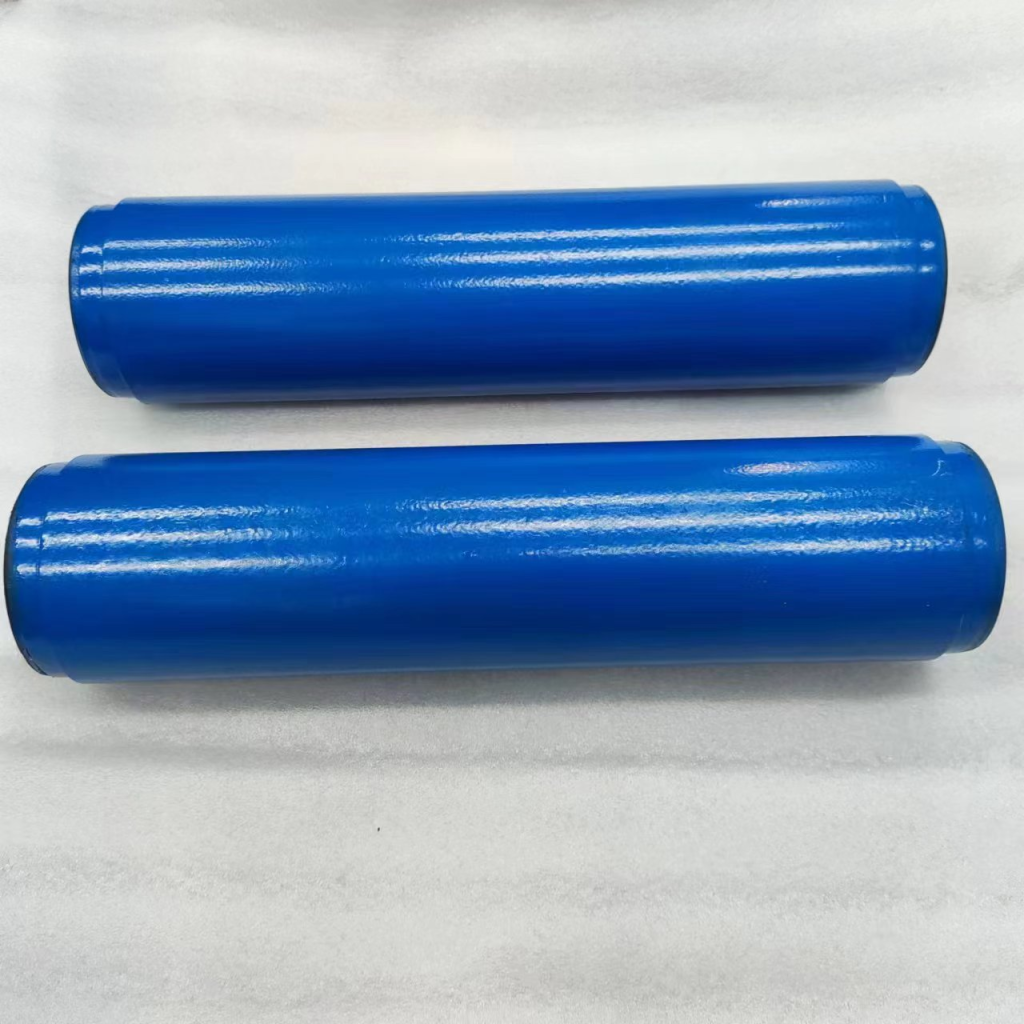

Stator Overview

seepex BN2-12L stator is a high-performance stator launched by seepex, which is widely used in various fields. As one of the core components of the pump, the performance of the stator directly affects the working efficiency and service life of the entire pump.

Application Field

seepex BN2-12L stator can be widely used in:

| Food and beverage industry | used to transport various thick, viscous or solid particle-containing fluids, such as chocolate, sauces, etc. |

| Papermaking industry | used to transport pulp and other fibrous slurries. |

| Chemical industry: | used to transport various chemical raw materials and products, such as acids, alkalis, solvents, etc. |

| Environmental protection field: | used to transport sludge, sewage, etc. |

| Mining field: | used to transport slag, slurry, etc. |

| Pharmaceutical industry: | used to transport various pharmaceuticals and biological products. |

Advantages Summary

- Wide applicability: seepex BN2-12L stator can be widely used in multiple industries to meet the transportation needs under various working conditions.

- Excellent performance: high-quality materials and careful design ensure the high efficiency, reliability and safety of the stator during use.

- Convenient use: the integral structural design greatly reduces the difficulty of maintenance and repair, and reduces the operation and maintenance costs.

- Economical and practical: with high comprehensive cost performance, it is an ideal choice for users in various industries.

Technical characteristics

- Excellent materials: the seepex BN2-12L stator is made of high-quality rubber material, with strong wear resistance and long service life.

- High sealing: the unique sealing design inside the stator can effectively prevent leakage and ensure the airtightness of the conveying process.

- High flow: the unique spiral channel structure inside the stator can achieve high flow conveying.

- Low pulsation: the optimized flow channel design can effectively reduce the pulsation during the conveying process and improve the smoothness of the conveying.

- Easy maintenance: the stator adopts an integral structural design, which is relatively simple to disassemble and repair.

people also ask

Send Your Enquiry :