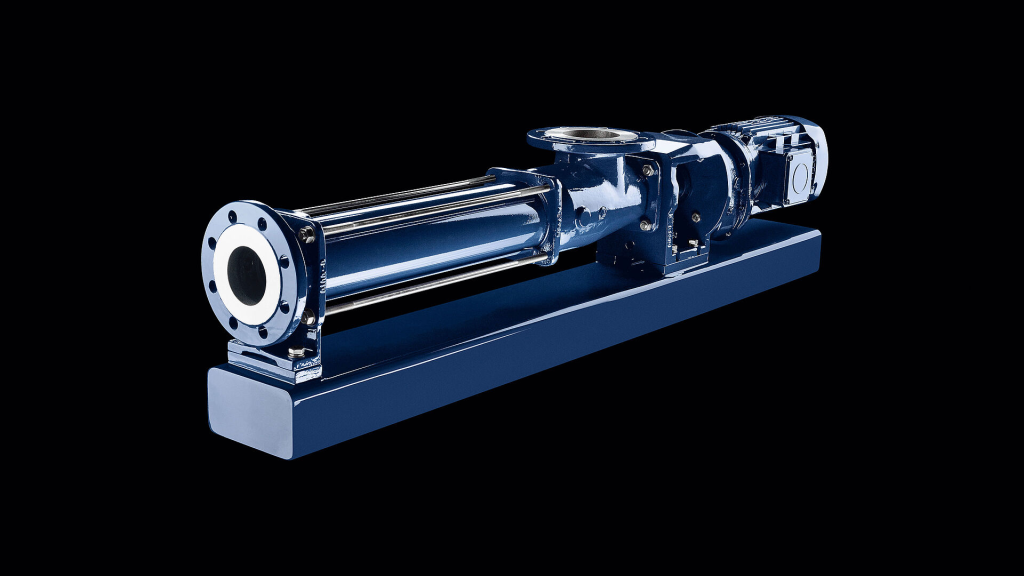

Parameters

| Voltage: 380V | Lift: 60m |

| Pump shaft position: horizontal | Impeller suction mode: single suction |

| Material: stainless steel | Weight: 78kg |

| Flow rate: 1.5m³/h | Speed: 200RPM |

| Drive mode: electric | Pressure: 0.5Mpa |

| Scope of application: sewage treatment | Application: metering pump |

| Model: BN2-6L | Brand: SEEPEX |

Advantages

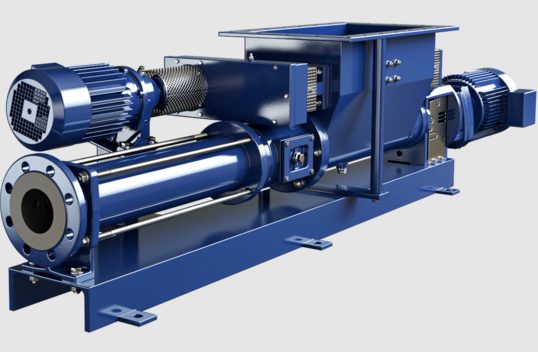

Compared with traditional centrifugal pumps, the unique design of seepex BN2-6L brings many advantages. First, it has excellent self-priming ability and can directly suck liquid from the bottom of the tank without auxiliary suction device. Secondly, the flow adjustment flexibility of seepex BN2-6L is very strong and can meet the needs of various working conditions.

Furthermore, it performs well in handling high-viscosity and easy-to-agglomerate media, avoiding the problem of pipeline blockage. In addition, seepex BN2-6L also has the advantages of wear resistance and low noise, which greatly improves the user experience.

It is worth mentioning that the seepex BN2-6L adopts a modular design, which is convenient for users to customize and maintain according to actual needs. The rotor and stator are wearing parts, which can be replaced separately according to changes in working conditions, greatly reducing the cost of use.

At the same time, this model of pump body has a compact structure and small installation space requirements, and can be widely used in small sites.

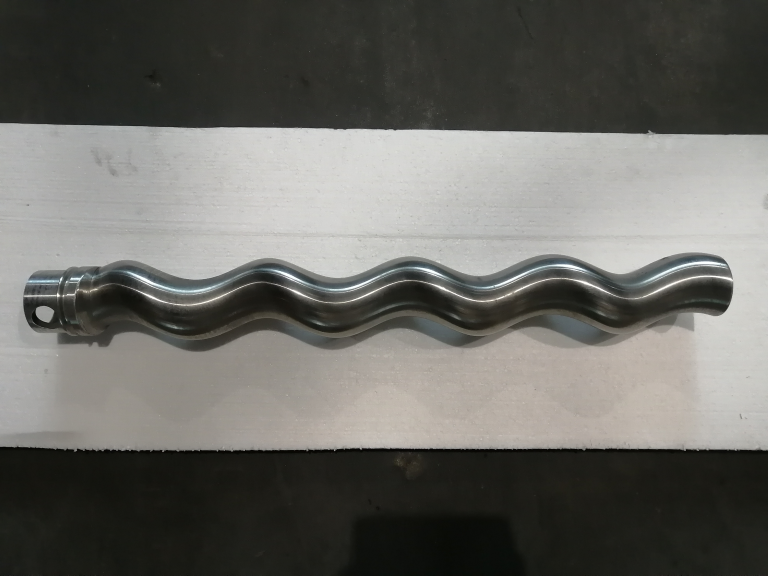

The rotor is the core component of the pump. Its spiral blades cooperate with the special curved shape of the inner wall of the stator to form a closed cavity.

When the rotor rotates under the action of the drive motor, these cavities will move one by one along the pump shaft, thereby transporting the medium from the inlet end to the outlet end.

people also ask

Send Your Enquiry :