[wpseo_breadcrumb]

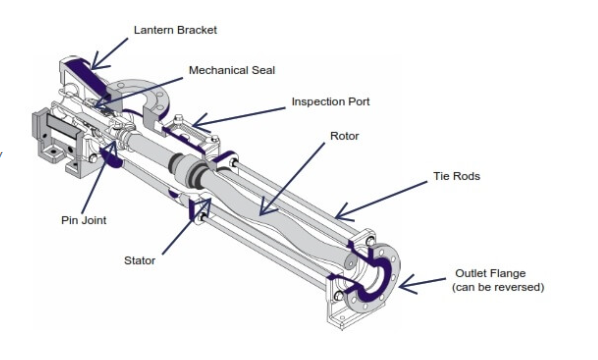

Design features

The design of Seepex BN2-6L rotor is both innovative and practical, suitable for a variety of industries, including chemical, food, pharmaceutical, etc. Its biggest features are:

- Efficient conveying: Thanks to the precise spiral structure, the fluid can remain stable during the conveying process, reducing the shear effect, and is suitable for conveying temperature-sensitive materials.

- Strong durability: Made of high-strength materials, it has excellent wear resistance and corrosion resistance, and can adapt to various complex working environments.

- Low maintenance cost: The design of Seepex BN2-6L rotor makes maintenance and servicing easier, reducing operating costs.

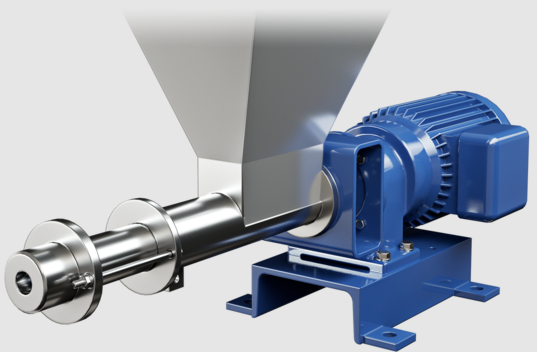

Applications

- Food Industry

In the food industry, the hygiene and safety of pumps are crucial. The Seepex BN2-6L rotor, with its smooth surface and high corrosion resistance, can effectively prevent bacterial growth and is easy to clean, meeting food safety standards. It is often used to transport dairy products, biological fermentation broth and other viscous foods. - Chemical Industry

In chemical production, the powerful performance of the BN2-6L rotor is reflected in its ability to handle a variety of corrosive liquids. Because its material can resist the erosion of a variety of chemicals, Seepex pumps have become an ideal choice for chemical companies to handle reactants and waste liquids. - Wastewater Treatment

Wastewater treatment is a field that requires the treatment of various fluids with complex physical and chemical properties. The Seepex BN2-6L rotor is designed to cope with the presence of solid particles in sewage, ensure smooth fluid transportation, and extend the service life of the equipment.

Performance Advantages

Efficient transportation: The BN2-6L Rotor has a stable flow output and can adapt to fluids of different viscosities, ensuring stability and continuity in the production process.

Easy to maintain: The design of the rotor makes daily maintenance very simple. Operators can quickly check and replace, reducing downtime.

Strong adaptability: Whether it is food processing, chemical industry or wastewater treatment, Seepex BN2-6L Rotor can perform well and adapt to different working environments and process requirements.

people also ask

Send Your Enquiry :