Advantages

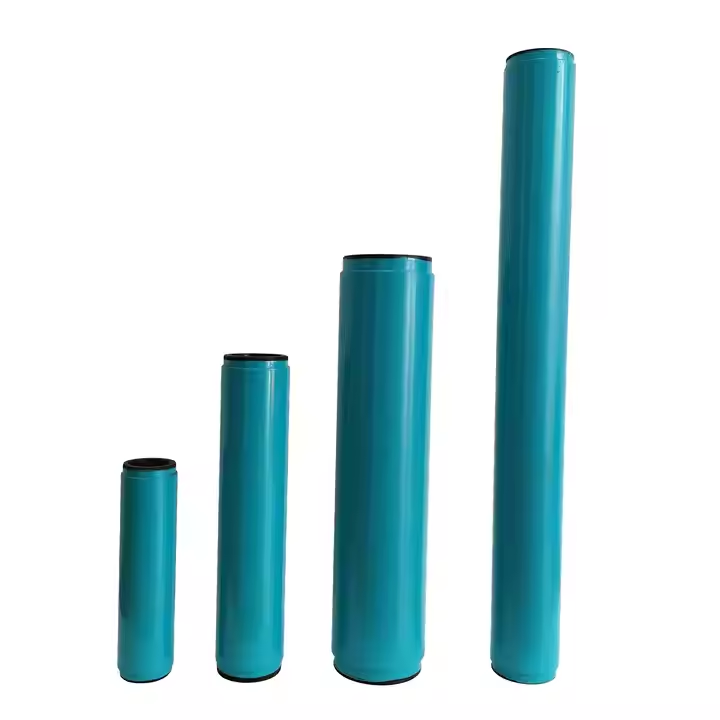

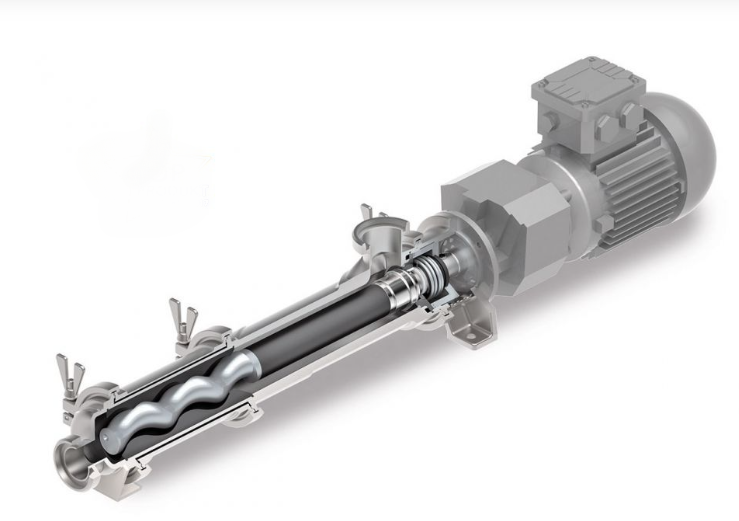

The Seepex BN17-12L rotor is made of high-quality materials and has excellent wear and corrosion resistance. Safety and hygiene are particularly important in the food processing and chemical industries. The BN17-12L’s dead-angle design ensures that the fluid will not be retained during the rotor flow, reducing the risk of bacterial growth. This feature enables it to meet strict hygiene standards when conveying juice, dairy products and other sensitive liquids.

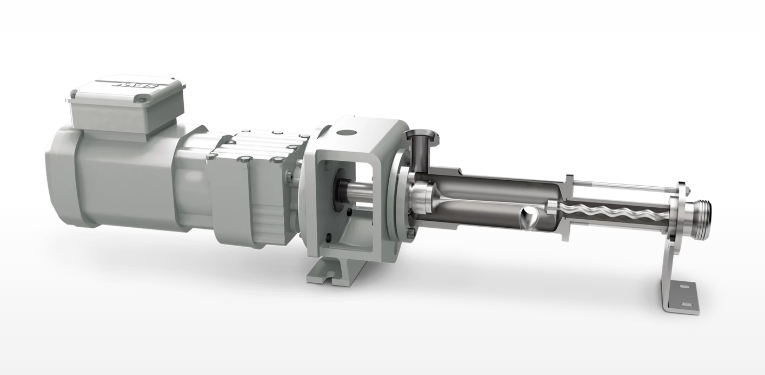

In addition, the rotor performs well in terms of energy consumption. Compared with traditional pumps, the seepex BN17-12L rotor requires significantly less energy during operation. This feature not only helps companies reduce operating costs, but also meets the current society’s needs for energy conservation and environmental protection, and promotes sustainable development.

In terms of installation and maintenance, the seepex BN17-12L rotor is simple in design, which is convenient for users to perform daily inspections and replacements. This not only reduces maintenance costs, but also improves the overall work efficiency of the equipment. In terms of environmental protection, the rotor reduces energy consumption during operation, which enables companies to achieve green production while pursuing economic benefits.

Applications

The Seepex BN17-12L rotor is particularly widely used in food processing, chemical industry, sewage treatment and other fields. For example, in the food industry, the safety and sanitation of the rotor are crucial. The BN17-12L rotor adopts a dead angle-free design, which can effectively prevent the accumulation of impurities and meet food safety standards. This enables it to maintain good flow performance and product quality when conveying liquids such as juices and seasonings.

In the chemical industry, the design of the annular rotor can efficiently handle liquids containing solid particles without clogging the system. This feature significantly improves the flowability of the production process and reduces maintenance costs. The high efficiency of the Seepex BN17-12L rotor ensures the optimization of energy utilization, thereby reducing operating costs and improving overall economic benefits.

Features

- High wear resistance

Made of advanced materials, it can resist wear and extend service life. - Superior self-priming ability

When handling viscous and granular materials, it can quickly and effectively self-prime. - Excellent corrosion resistance

Suitable for a variety of chemical processing to ensure the stability of the equipment. - Smooth conveying

The design ensures smooth fluid conveying and reduces cavitation and vibration. - Easy installation and maintenance

The structural design is easy to disassemble and assemble, reducing maintenance costs and improving work efficiency. - Meet hygiene standards

Ensure that the fluid is not contaminated in the food and beverage industry and meet industry requirements. - Energy saving and environmental protection

Low energy consumption during operation helps enterprises achieve green production goals.

people also ask

Send Your Enquiry :