Parameters

| Material: stainless steel | Working pressure: 1.2MPa | Voltage: 380V | Pump shaft position: horizontal |

| Flow rate: 8m³/h | Application scope: 60% water content | Drive mode: electric | Transport medium: sewage pump, impurity pump |

| Impeller structure: single impeller | Speed: 2RPM | Weight: 80kg | Lift: 120m |

| Product features: 304 | Impeller suction mode: single suction | Application: sewage pump | Performance: high pressure |

| Brand: SEEPEX | Suction distance: 10m | Pressure: 1.2Mpa | Model: BN17-12 |

Introduction

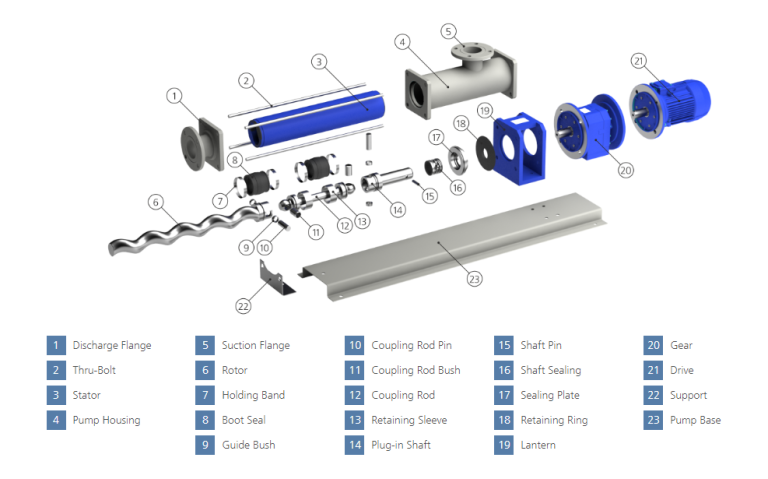

As the rotor rotates within the stator, a changing cavity is formed. Fluid is sucked into the cavity, and as the rotor rotates, the cavity volume gradually decreases, and the fluid is forced to move forward. This process not only ensures stable fluid delivery, but also operates at lower pressures, thereby improving the efficiency of the pump.

The Seepex BN17-12L pump is widely used in multiple industries.

In the food industry, the pump is often used to transport fluids such as syrups, juices, and dairy products, and is favored for its good hygiene standards and lossless delivery characteristics. In the chemical industry, it can efficiently transport viscous and corrosive fluids such as resins and adhesives. In addition, in the field of sewage treatment, the BN17-12L pump is also capable of handling sewage containing solid particles.

The design of the Seepex BN17-12L pump gives it a variety of advantages. First, the materials of its rotor and stator can be customized according to the properties of the specific fluid to improve its corrosion resistance and service life.

Secondly, the maintenance of the pump is relatively simple, and users can easily perform daily inspections and maintenance, reducing maintenance costs. Furthermore, due to its efficient fluid transfer capabilities, users can significantly reduce energy consumption, which is especially important during long operating hours.

people also ask

Send Your Enquiry :