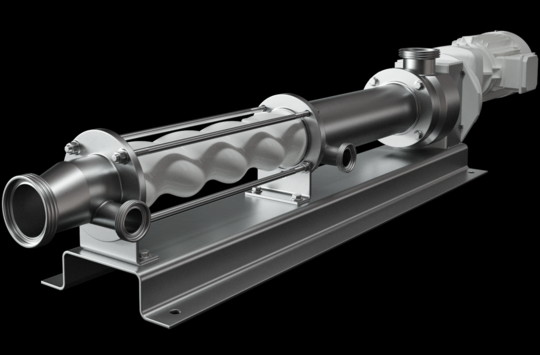

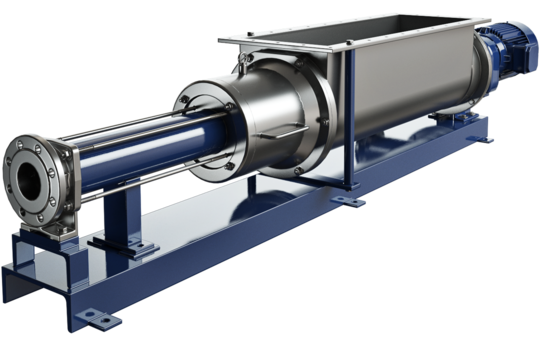

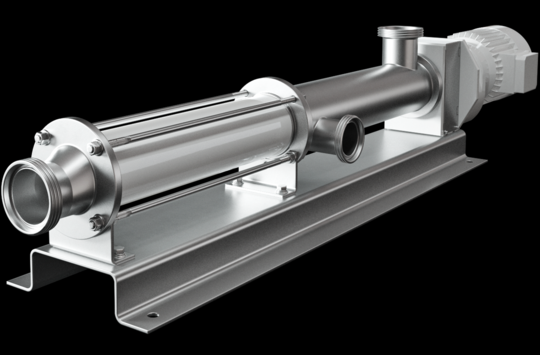

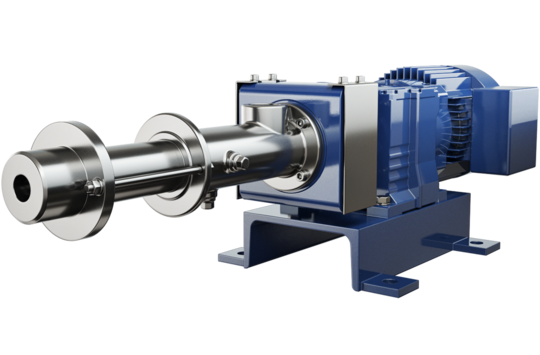

BN10-12L seepex BN

Technical parameters Drive mode: Electric Lift: 60m Output flow: 200 Model: BN10-12 Weight: 80kg Conveying medium: Clean water pump Efficiency: 98% Material: Stainless steel Flow rate: 2.6-12 (m3/h) Pump shaft position: Horizontal Discharge diameter: DN50 (mm) Application: Metering pump Performance: Wear-resistant Number of impellers: Single stage Suction diameter: DN65 (mm) Working temperature: Normal temperature Brand:…