[wpseo_breadcrumb]

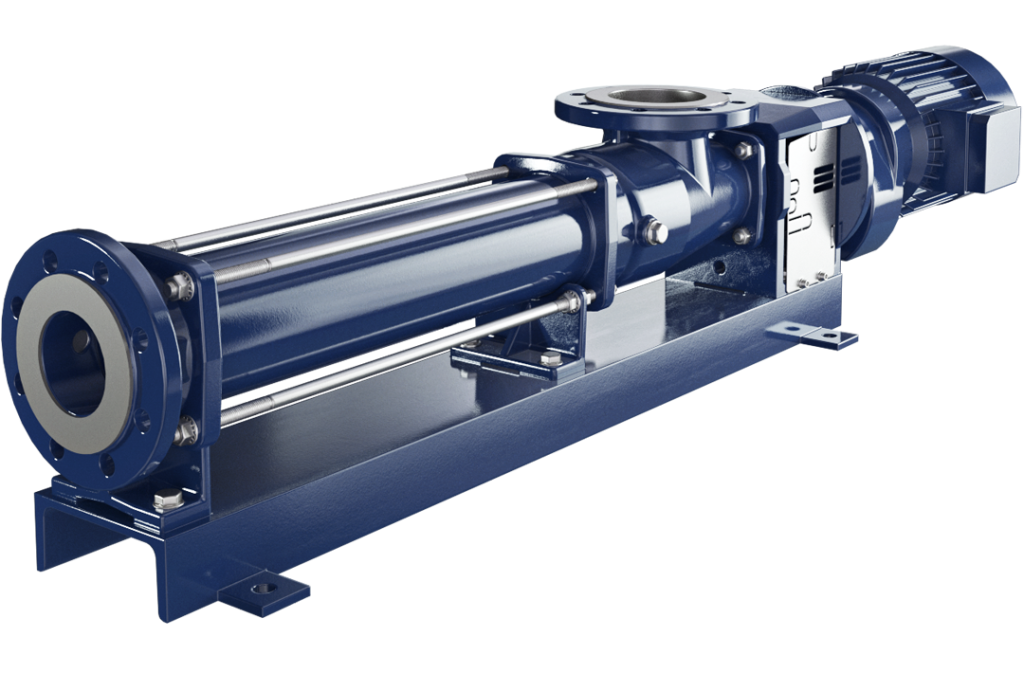

Parameters

- Parameters

- Power: 3.5 (kw)

- Lift: 60 (m)

- Suction diameter: DN100 (mm)

- Shaft power: 3.5

- Performance: wear-resistant

- Material: stainless steel

- Pump shaft position: horizontal

- Weight: 100 (kg)

- Conveying medium: clean water pump

- Brand: seepex

- Model: BN75-6LT

- Discharge diameter: DN100 (mm)

Introduction

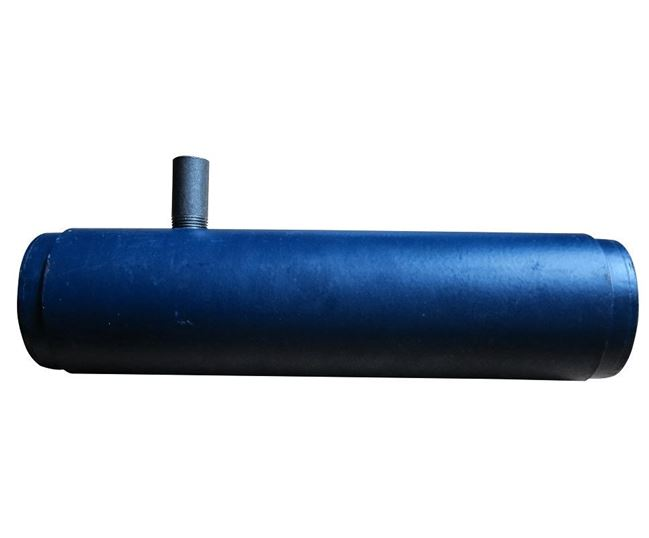

In the Seepex BN75-6LT, the rotor is the key component of the pump, which is responsible for driving the flow of fluid. The rotor changes the volume in the pump by rotating, thereby achieving the suction and discharge of liquid. The stator opposite the rotor is the fixed part of the pump, which is usually made of elastic material to ensure good sealing even under high pressure.

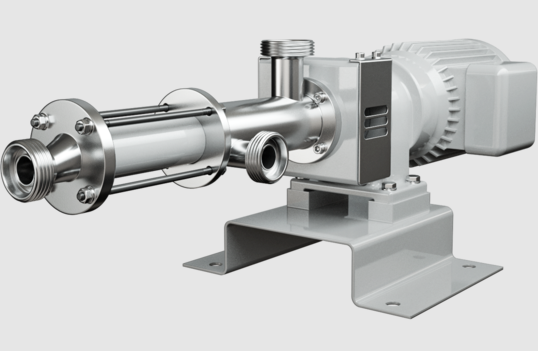

When the rotor rotates, the space in the stator gradually increases, forming a negative pressure, which in turn sucks the liquid in; when the rotor continues to rotate, the space gradually decreases, causing the liquid to be squeezed and discharged. This design not only improves the efficiency of liquid delivery, but also effectively reduces shear force and protects the structure of the liquid, especially when dealing with perishable fluids.

Seepex BN75-6LT has demonstrated its strength in many industries, including food processing, chemicals, and pharmaceuticals. In the food industry, it can gently handle viscous substances such as syrups and jams; in the chemical field, it is often used to transport high-viscosity resins or coatings. In the pharmaceutical industry, its pollution-free delivery characteristics make the production of drugs safer and more reliable.

people also ask

Send Your Enquiry :