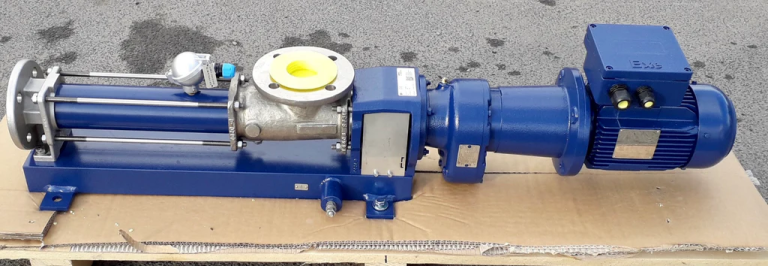

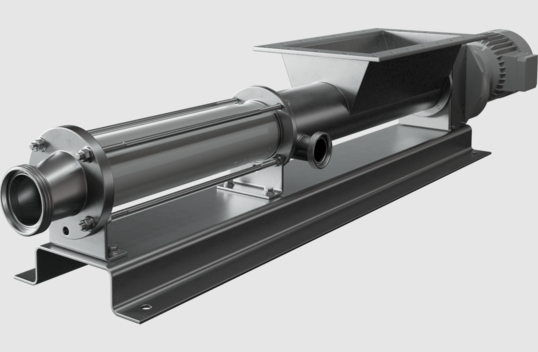

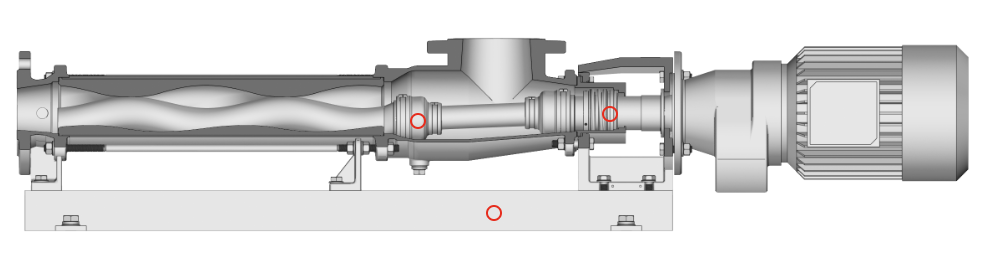

BT STANDARD OPEN HOPPER PUMP

The SEEPEX BT STANDARD OPEN HOPPER PUMP is the universal range within the SEEPEX hopper pump group. With its large rectangular hopper, screw conveyor and a compression zone, it effortlessly conveys highly viscous products with low flowability.

Efficient Handling of Viscous and Solid-Laden Media: The SEEPEX BT Standard Open Hopper Pump

The SEEPEX BT Standard Open Hopper Pump is a high-performance pump that is specifically designed for the efficient handling of viscous and solid-laden media. This pump features an open hopper design, which allows for easy access and cleaning, as well as the ability to handle a wide range of materials with varying viscosities and concentrations. The pump also boasts a robust construction and features high-quality components, ensuring reliable and long-lasting performance. In addition, the pump’s design allows for low pulsation and shear, minimizing product degradation and ensuring optimal product quality. Overall, the SEEPEX BT Standard Open Hopper Pump is an ideal solution for applications requiring efficient and reliable pumping of challenging media.

The SEEPEX BT Standard Open Hopper Pump offers a variety of features that make it an ideal choice for handling challenging media

- Open hopper design for easy access and cleaning

- Ability to handle viscous and solid-laden media with varying viscosities and concentrations

- Robust construction and high-quality components for reliable and long-lasting performance

- Low pulsation and shear, minimizing product degradation and ensuring optimal product quality

- Versatility to handle a wide range of applications across multiple industries

- Compact design for easy installation in tight spaces

- Energy-efficient operation for reduced operating costs

- Customizable options to meet specific application needs

The SEEPEX BT Standard Open Hopper Pump is suitable for a wide range of applications in various industries

- Chemicals: The pump can handle viscous chemicals, abrasive media, and hazardous liquids with ease, making it ideal for chemical processing.

- Food and Beverage: The open hopper design allows for easy cleaning and handling of solid and semi-solid food products, making it ideal for the food and beverage industry.

- Wastewater Treatment: The pump’s ability to handle solids-laden media makes it an excellent choice for wastewater treatment plants.

- Mining: The pump’s robust construction and ability to handle abrasive slurries make it well-suited for mining applications.

- Oil and Gas: The pump can handle high-viscosity oils and other challenging fluids found in oil and gas production.

- Pharmaceuticals: The low-pulsation and low-shear features make it an ideal choice for transferring sensitive pharmaceutical products.

People Also Ask

Send Your Enquiry :