The Versatility of SEEPEX Progressive Cavity Pumps with N Module

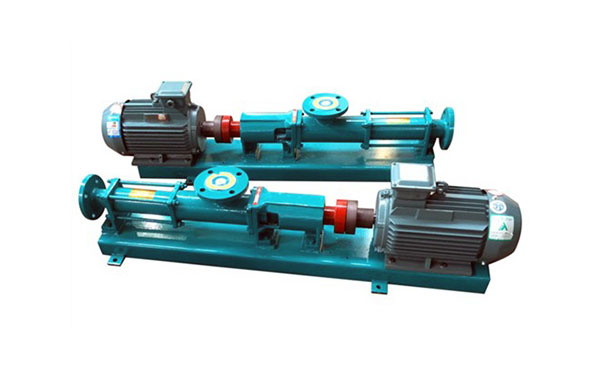

The BN module forms the robust basis for all SEEPEX progressive cavity pumps. It can pump low-viscosity to viscous media, with and without solids, and can be used in virtually all industries from the environmental industry to the chemical industry and food production. The seepex pumps are fitted with round flanged suction and pressure connections, as well as large spherical inlet openings for the simple intake of media that contain solids.

High Performance and Reliability

SEEPEX BN pumps with block design are progressive cavity pumps that offer a high level of performance and reliability. These pumps are designed to handle a wide range of fluids, including highly viscous and abrasive liquids.

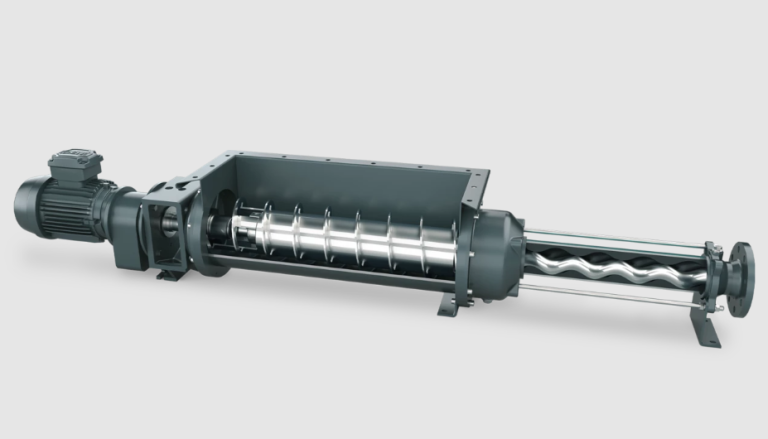

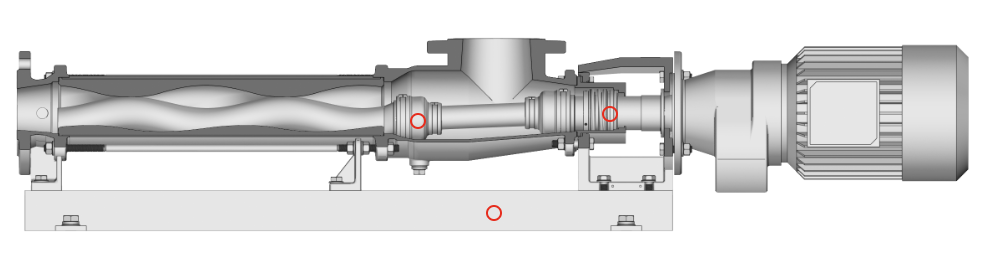

The block design of the SEEPEX BN pump provides many benefits, including a compact size, reduced installation space requirements, and simplified maintenance. The pump’s rotor and stator are housed in a single block, which reduces the number of parts required for assembly and makes maintenance easier. These seepex pumps are ideal for a variety of applications, including chemical processing, food and beverage production, wastewater treatment, and more. They offer excellent flow rates and can handle solids up to 1 inch in diameter.

Versatile Applications of SEEPEX BN Pumps with Block Design

- Block Design: The seepex pump housing and bearing bracket are designed as a single-piece block, which provides excellent stability and rigidity, as well as enhanced resistance to external forces.

- Low Noise: EEPEX BN pumps feature a unique impeller and diffuser design, which results in minimal hydraulic noise and vibration levels during operation.

- High Efficiency: These pumps are designed for high efficiency, with optimized hydraulic components that provide maximum energy savings.

- Easy Maintenance: SEEPEX progressive cavity pump is designed for easy maintenance, with simple access to all wearing parts and a modular design that allows for quick and easy replacement of components.

- Wide Range: The pumps are available in a wide range of sizes and materials, making them suitable for a variety of applications in various industries.

- Corrosion-resistant: The progressive cavity pump housing is made of stainless steel, which makes the pump highly resistant to corrosion and rust.

- Self-Priming: EEPEX BN pumps are self-priming and can handle liquids with up to 10% gas content, making them ideal for pumping fluids from tanks or pits.

The Application of SEEPEX BN Progressive Cavity Pump

SEEPEX BN pumps with block design are versatile and can be used in various industries for efficient fluid transfer. They are suitable for pumping corrosive chemicals, sludge, sewage, viscous substances, and more. The stainless steel construction makes them corrosion-resistant, and their self-priming capability allows them to handle liquids with up to 10% gas content. With their low noise, high efficiency, and easy maintenance features, EEPEX BN pumps are a reliable and cost-effective solution for many fluid transfer applications.

People Also Ask

Send Your Enquiry :