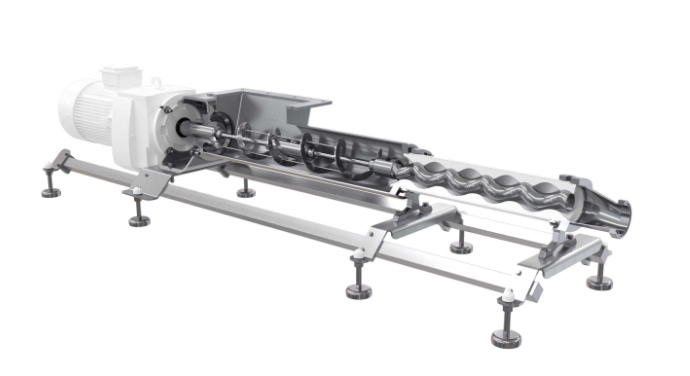

Features of Seepex BN5-48 Rotor

First of all, the Seepex BN5-48 rotor is designed with highly wear-resistant materials and can work stably for a long time in various harsh environments. This rotor is particularly suitable for handling viscous liquids and solid particles, and is widely used in industries such as food, medicine, chemical industry and sewage treatment. Its unique spiral shape design makes the liquid flow more stable, significantly improves the efficiency of the pump and reduces energy consumption. This allows companies to effectively control maintenance and operating costs.

The maintenance of the Seepex BN5-48 rotor is also very convenient. The maintenance of traditional pumps usually requires complex disassembly and assembly, while the Seepex design effectively simplifies this process. Users can quickly replace rotor components, reduce equipment downtime, and ensure the continuous operation of the production line. This efficient maintenance method enables companies to respond to various emergencies more flexibly in daily operations.

The Seepex BN5-48 rotor also has significant advantages in environmental protection. With the global attention to environmental protection, the use of high-efficiency and low-energy consumption equipment has become an inevitable trend. Seepex BN5-48 rotor helps enterprises reduce emissions through its excellent energy efficiency performance, which is in line with the concept of green production. This not only wins market competitiveness for enterprises, but also promotes sustainable development.

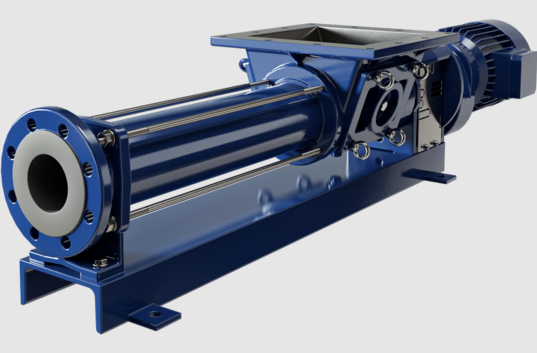

Seepex BN5-48 rotor has shown strong competitiveness in applications in different industries due to its excellent performance characteristics, convenient maintenance design and environmentally friendly operation mode. From food processing to chemical industry, this rotor can meet high standards of fluid transportation requirements. Choosing Seepex BN5-48 rotor will play an important role in improving production efficiency, reducing operating costs and achieving sustainable development goals.

Areas of application of seepex BN5-48 Rotor

- Food and Beverage Industry

In food processing, the seepex BN5-48 rotor safely and efficiently conveys viscous materials such as syrups, purees and dairy products. Its materials meet food safety standards, ensuring that product quality is not affected during processing. - Chemical Industry

In the chemical industry, this rotor is used to convey high-viscosity liquids and media containing solid particles, such as coatings, paints and chemical solvents. Its corrosion resistance ensures stability and safety when handling a variety of chemicals. - Wastewater Treatment

The seepex BN5-48 rotor plays an important role in wastewater treatment facilities, effectively handling solids and thick sludge. Its self-cleaning properties reduce the risk of clogging and improve equipment reliability and maintenance efficiency. - Pharmaceutical Industry

In the pharmaceutical industry, this rotor is used to convey pharmaceutical raw materials and other high-viscosity fluids to ensure a pollution-free and high-precision production process. This is essential to ensure the quality of drugs. - Papermaking industry

In the papermaking process, seepex BN5-48 rotor is used to transport pulp and additives. Its stable flow control effect helps to improve paper quality and production efficiency.

people also ask

Send Your Enquiry :