[wpseo_breadcrumb]

Design features

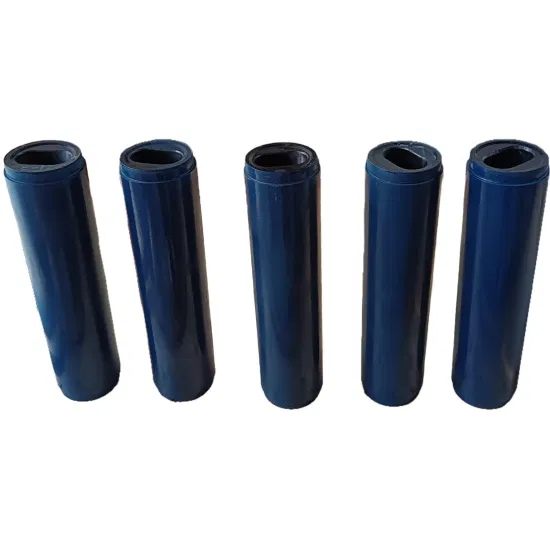

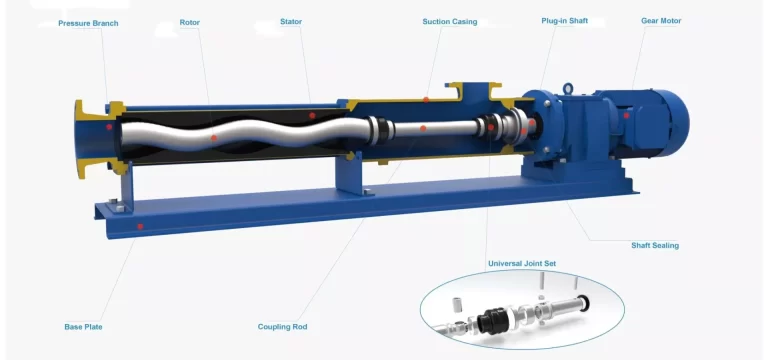

The design of the seepex BN1-6L rotor focuses on efficient conveying and durability. The rotor is made of high-quality materials and performs well in terms of resistance to wear and corrosion. This allows it to operate continuously in a variety of harsh environments and meet the needs of different fluid conveying. Its special geometry ensures uniform fluid conveying and reduces flow instability, providing reliable support for the handling of viscous liquids and applications containing solid particles.

Advantages

- Excellent durability

The BN1-6L rotor is made of high-quality materials and has excellent wear and corrosion resistance, ensuring long-term operation in harsh environments. - Efficient conveying

The design of the rotor ensures uniform fluid conveying, can effectively handle viscous and solid-containing liquids, and reduce flow instability. - Self-cleaning function

The design has the characteristics of preventing material retention, reducing the risk of blockage, reducing maintenance frequency, and improving the operating reliability of the equipment. - Compliance with hygiene standards

When used in the food and pharmaceutical industries, the rotor material meets the relevant hygiene standards to ensure safety and pollution-free during the conveying process. - Easy maintenance

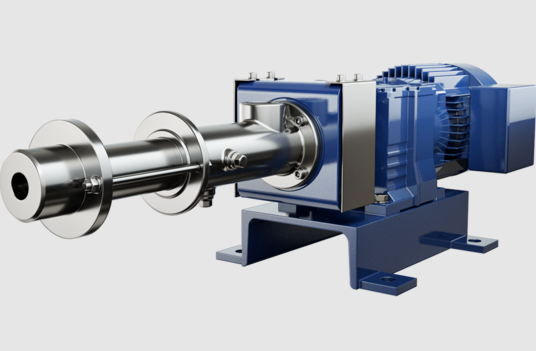

The rotor structure makes disassembly and cleaning simple, reducing downtime and thus improving production efficiency. - Wide applicability

It is suitable for a variety of industries, including food, chemical and pharmaceutical fields, and can meet the needs of different fluid conveying. - Energy saving effect

The efficient design reduces energy consumption, making it excellent in economic performance and suitable for long-term use.

Application areas

- Food and beverage industry

In the food and beverage industry, the seepex BN1-6L rotor is widely used to convey syrups, juices and other viscous materials. Its materials meet food safety standards to ensure that no contamination will occur during processing. - Chemical industry

In the chemical industry, the rotor can safely and effectively convey a variety of chemicals, including viscous liquids and slurries. Excellent corrosion resistance makes it perform well when handling irritating or corrosive substances. - Pharmaceutical industry

The seepex BN1-6L rotor has extremely high hygiene requirements in the pharmaceutical industry, so its design takes into account the anti-contamination factor to ensure the clean and safe delivery of pharmaceutical raw materials.

people also ask

Send Your Enquiry :