Introduction

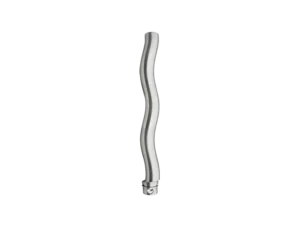

The seepex BN35-6L rotor uses high-strength materials to ensure stable operation in harsh environments. This rotor design effectively reduces the shear force of the fluid in the pump and protects the fragile material properties, especially when handling emulsions or suspensions. In addition, the rotor geometry has been carefully calculated to ensure efficient flow under different working conditions.

Secondly, the superior performance of the seepex BN35-6L rotor is not only reflected in the flow rate, but also in its lower energy consumption. Compared with traditional pumps, the seepex BN35-6L rotor consumes significantly less energy during operation, thus saving operating costs for enterprises.

The seepex BN35-6L rotor is also very easy to maintain. Its modular design allows maintenance personnel to quickly replace or repair the rotor, greatly reducing downtime and improving production efficiency.

Application areas

In the food industry, the leak-free design and hygiene level of the seepex BN35-6L rotor make it an ideal choice for handling food and beverages. Many food processing plants use this rotor to convey juices, sauces and other viscous materials, ensuring product quality and safety.

In terms of environmental protection, the use of the seepex BN35-6L rotor can reduce energy consumption because it can achieve efficient fluid transportation with lower power requirements. This not only reduces the company’s operating costs, but also reduces the impact on the environment.

Advantages

- High Wear and Corrosion Resistance

- The Seepex BN35-6L rotor is made from high-quality materials, ensuring durability in various media, making it particularly suitable for the chemical and food industries.

- Stable Flow Output

- This rotor design provides consistent flow, reducing fluctuations and ensuring stable processes and product quality.

- Low Energy Consumption

- Compared to traditional pumps, the BN35-6L rotor operates with lower energy consumption, helping businesses save on operational costs and improve economic efficiency.

- Easy Maintenance

- Its modular design simplifies the process of replacement and maintenance, reducing downtime and enhancing production efficiency.

- Strong Adaptability

- The rotor can operate reliably under extreme conditions, such as high temperatures and pressures, making it versatile for various industrial applications, including wastewater treatment and petrochemicals.

- Increased Production Efficiency

- With its efficient design, the rotor can quickly respond to production demands, helping companies achieve higher efficiency and flexibility.

people also ask

Send Your Enquiry :