[wpseo_breadcrumb]

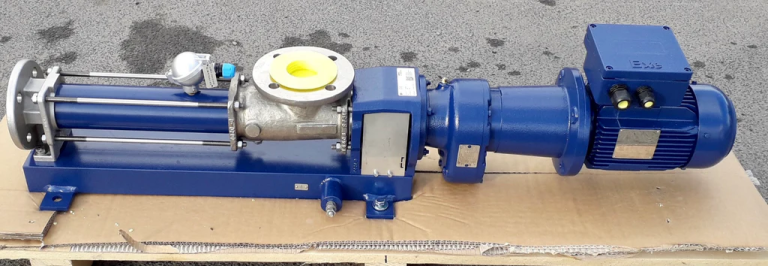

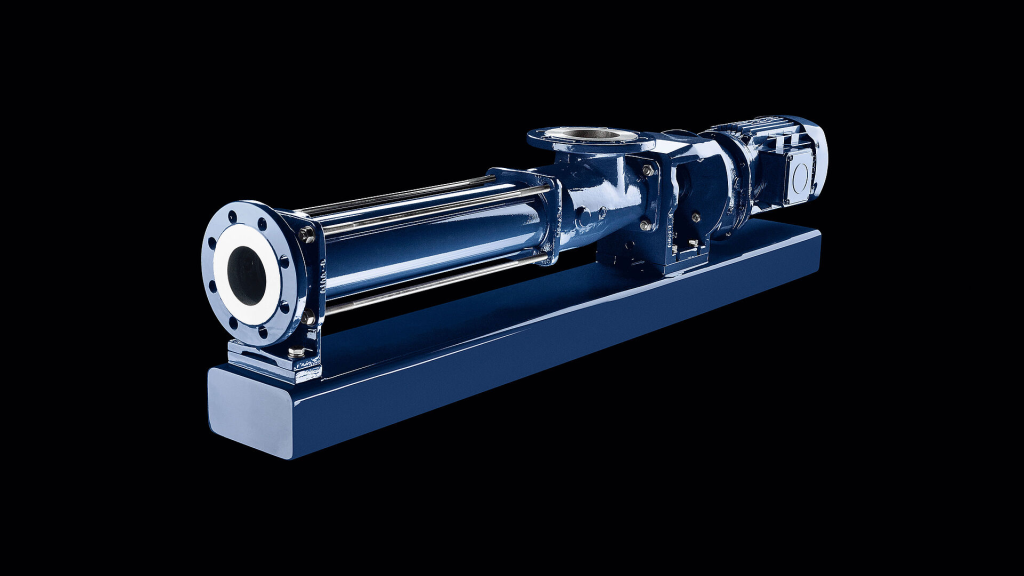

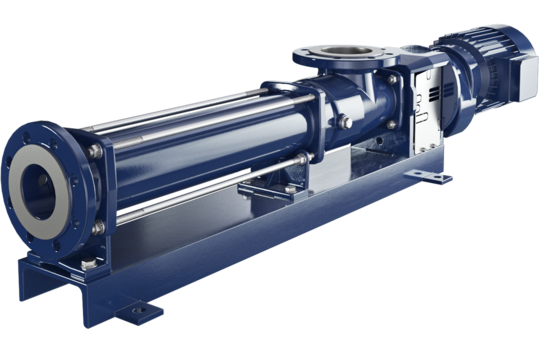

The N series screw pump is a classic pump type in the SEEPEX modular product system. In all industrial fields, this series of pumps is widely used to transport various media with different viscosities and different solid contents. Depending on the working conditions, various geometries (conventional, 6L long lead, triangular geometry, and constant wall thickness) of stators and rotors are available for selection. These and other advantages ensure efficient operation of the entire pump system.

seepex BN5-48 has excellent anti-clogging performance. It is equipped with a specially designed cutting device, which can effectively crush solid particles in the pumping process and prevent the occurrence of pipeline blockage. At the same time, the equipment uses wear-resistant materials and has a service life of more than 10 years, which greatly reduces the cost of maintenance and repair.

It is worth mentioning that seepex BN5-48 also performs well in pollutant removal efficiency. By optimizing the pumping process, the equipment can better separate and remove organic matter, suspended matter, etc. in sewage, providing a guarantee for subsequent deep treatment.

In addition, seepex BN5-48 also has excellent compatibility. This equipment can be seamlessly connected with various common sewage treatment systems without large-scale system transformation, which greatly reduces the user’s investment cost. At the same time, the maintenance of the equipment is relatively simple, and users can easily cope with daily maintenance work.

Main parameters

Conveying capacity: 30 l/h–500 m³/h

Pressure: up to 96 bar

Features

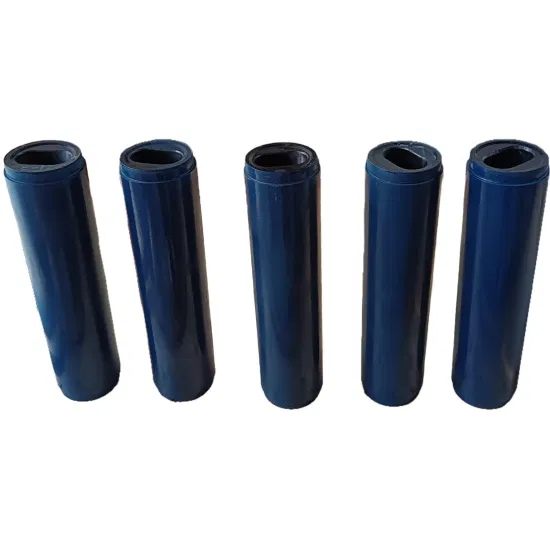

Various stator/rotor geometries (conventional, 6L long lead, triangular geometry, and constant wall thickness)

Low pulse, uniform and adjustable flow. No pulsation buffer or compensation device is required.

Strong self-priming ability, even if the medium is a gas-liquid mixture, it can reach 9 m water column

Flexible installation, can be installed horizontally or vertically, and the suction chamber inlet direction is adjustable

Large particle size material conveying capacity, improved solid handling capacity y Gentle conveying of materials containing solid components to ensure that the solid components are conveyed without loss

Reversing and reversing the input and output direction can improve NPSHr and sealing performance

Low shear performance.

Send Your Enquiry :