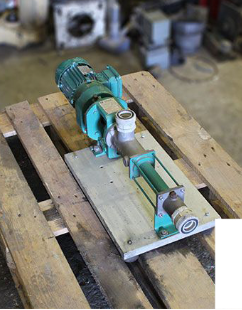

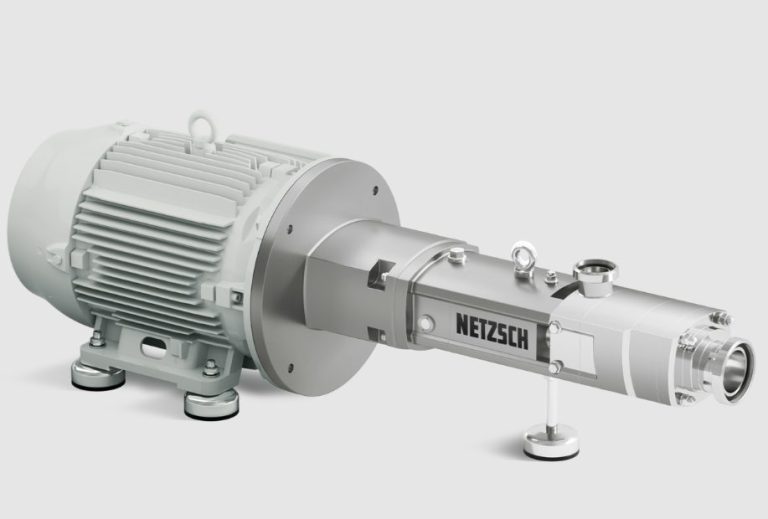

Netzsch NM021by01l06b

Netzsch NM021by01l06b

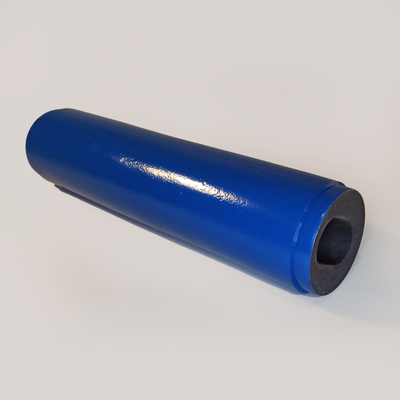

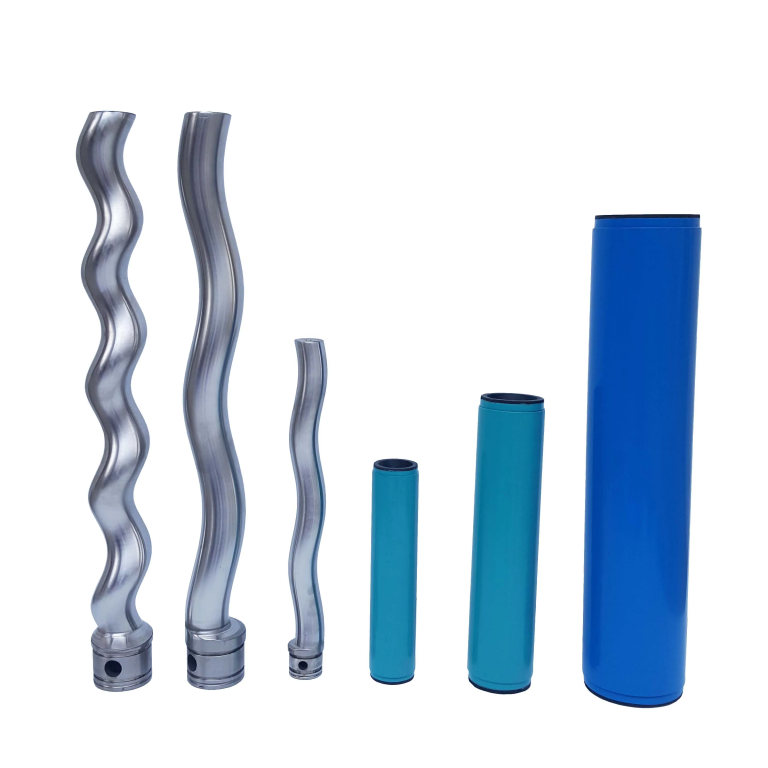

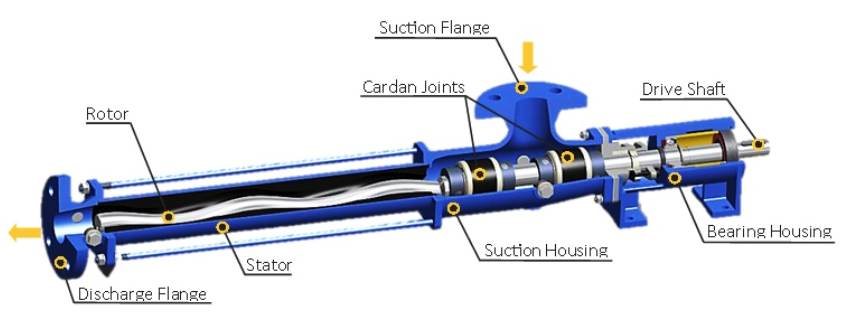

- The Netzsch NM021by01l06b connecting Rod Group is an important Netzsch pump parts, comprising connecting rod, universal joint, coupling rod, guide bush, rubber rings, and a rubber sheath, connecting rod pin, retaining sleeve, steel wire rings, drive shaft, etc.

- The connecting Rod Group must withstand both the force of the drive shaft and its own swinging longitudinal and transverse forces. These forces are cyclical and cause the connecting rods to be subjected to alternating loads such as compression and stretching, which can cause fatigue failure. Therefore, it’s crucial for Netzsch pump parts, especially the coupling rod, to have sufficient fatigue strength and structural stiffness. Otherwise, insufficient fatigue strength can lead to breakage of the connecting rod body or interface, resulting in major accidents and damage to the whole machine.

Netzsch NM021by01l06b function of connecting rod:

- High-quality construction: The Netzsch NM021by01l06b is built with high-quality materials to ensure durability and longevity.

- Compact design: This device is designed to be small and compact, making it easy to install in tight spaces.

- Low noise operation: The Netzsch NM021by01l06b operates quietly, making it suitable for use in environments where noise levels must be kept to a minimum.

- Efficient performance: With a maximum flow rate of 17 liters per minute, this pump delivers efficient performance for a wide range of applications.

- Easy maintenance: The Netzsch NM021by01l06b is designed for easy maintenance, with simple access to all components and easy-to-replace parts.Wide temperature range: This device can operate in temperatures ranging from -20°C to 90°C, making it suitable for use in a variety of environments.

- Chemical resistance: The Netzsch NM021by01l06b is resistant to a wide range of chemicals, making it suitable for use in demanding applications.

Netzsch NM021by01l06b Parameter Liat

| BRAND | Netzsch |

| INLET/OUTLET CONNECTION TYPE | NPT |

| INLET SIZE | 1-1/4 in |

| MATERIAL – HOUSING | 316 SS |

| MOTOR VOLTAGE | 230-460 VAC |

| HORSEPOWER | 1 |

People also ask :

[video_lightbox_youtube video_id=”JWkoODah0vY&rel=0″ width=”640″ height=”480″ alt=”Sludge Screw Pump” anchor=”https://pumpvv.com/wp-content/uploads/2023/03/pump-cover1.png”]

Send Your Enquiry :