Design Concept and Technical Features

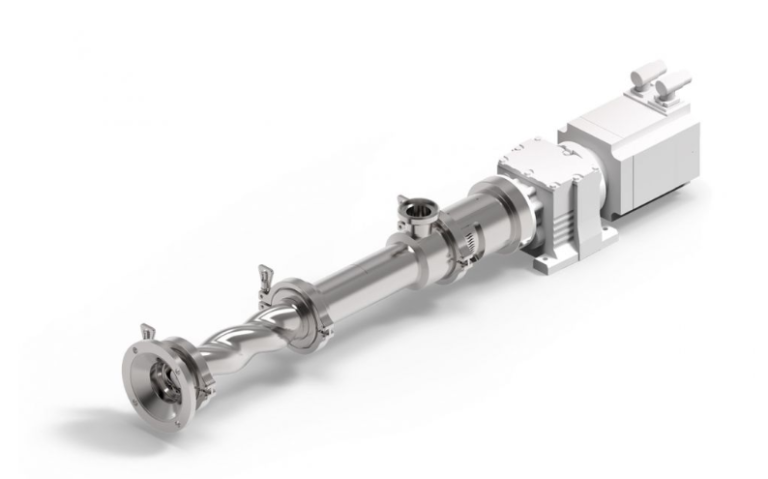

The seepex BN130-6L rotor is a screw pump rotor designed to improve the efficiency and reliability of fluid delivery. The rotor is made of highly wear-resistant alloy materials and combined with precision machining technology to ensure its extremely high durability and corrosion resistance under various working conditions. This allows it to operate continuously under extreme temperatures and pressures, meeting the modern industry’s demand for equipment durability.

The spiral shape of the rotor allows the fluid to maintain a good flow state during the delivery process, reducing the impact of shear force on the fluid. This feature is not only suitable for ordinary liquids, but also can effectively handle high-viscosity fluids, making it widely used in industries such as food, chemicals and medicine.

Material Selection

The use of high-quality materials is a major feature of the seepex BN130-6L rotor. The rotor is usually made of wear-resistant alloy materials and can withstand high temperatures, high pressures and corrosive media. This enables the rotor to effectively handle a variety of complex fluids in industries such as chemicals, food and pharmaceuticals.

Application Scenarios

The Seepex BN130-6L rotor is widely used in many industries due to its excellent performance.

- Chemical Industry

In the chemical production process, many raw materials are highly viscous and corrosive. The corrosion resistance and efficient conveying capacity of the Seepex BN130-6L rotor make it an ideal choice for this industry. - Food Industry

In food production, the performance of the pump directly affects the quality of the product. The Seepex BN130-6L rotor can efficiently convey fluids without damaging the ingredients, ensuring the safety and taste of the product. - Sewage Treatment

Sewage treatment plants require efficient and reliable pumping equipment. The Seepex BN130-6L rotor shows great advantages in treating sewage containing solid particles, which can effectively reduce treatment costs.

Efficiency and Economy

Another notable feature of the seepex BN130-6L rotor is its high energy efficiency. Compared with traditional pumps, this rotor pump consumes less energy at the same flow and head, saving the company’s operating costs. Energy saving can not only reduce the company’s electricity expenditure, but also conform to the concept of sustainable development advocated by today’s society.

In modern industry, the requirements for improving production efficiency and reducing energy consumption have become the core goals of enterprises. BN130-6L rotor has brought tangible benefits to the company’s production with its excellent design and high-efficiency working performance.

people also ask

Fill up and submit the below inquiry form, or directly write us an email: info@pumpvv.com