[wpseo_breadcrumb]

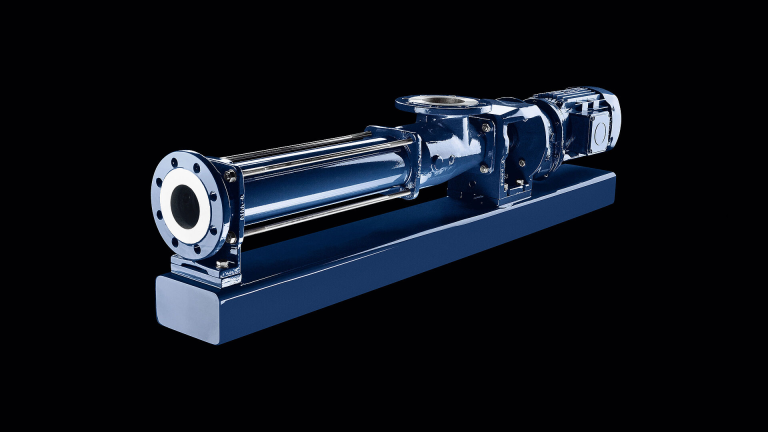

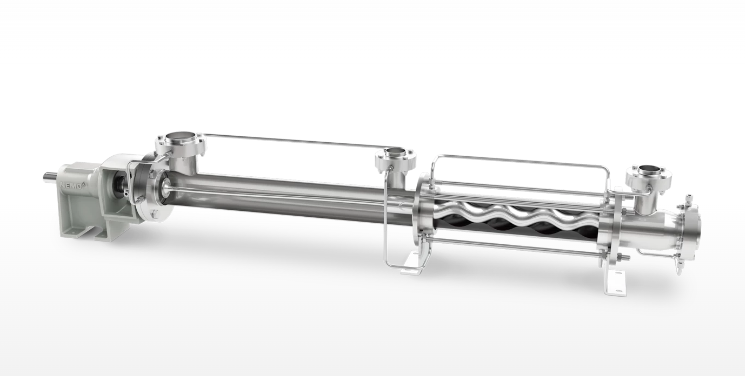

Features of Seepex BN70-18L stator

- Superior materials

The Seepex BN70-18L stator is made of high-quality materials with good corrosion resistance and wear resistance. This means that in harsh working environments, the stator can still maintain stable performance and ensure the normal operation of the pump. Its material selection takes into account the needs of various application scenarios, allowing it to perform well in industries such as chemical and food.

- Efficient fluid dynamic design

The design of the BN70-18L stator focuses on fluid dynamics principles and optimizes the fluid flow path. This design not only improves the working efficiency of the pump, but also effectively reduces energy consumption and helps companies save operating costs. The efficient fluid dynamic design enables the pump to maintain good performance when handling various liquids.

- Flexible compatibility

The Seepex BN70-18L stator is compatible with a variety of rotor models, and users can choose according to specific needs. This flexibility enables the BN70-18L stator to adapt to different application scenarios, improving the versatility and adaptability of the equipment.

Applications

- Chemical Industry

In the chemical industry, the BN70-18L stator is widely used to transport various chemical liquids. Its corrosion resistance enables it to safely handle hazardous chemicals such as strong acids and alkalis.

- Food Industry

The food industry has extremely high requirements for the hygiene and safety of pumps. The design of the Seepex BN70-18L stator meets food safety standards and can effectively prevent contamination while maintaining the purity of the fluid.

- Environmental Protection Industry

In sewage treatment and wastewater management, the BN70-18L stator plays an indispensable role. Its strong conveying capacity and durability ensure the efficient operation of sewage treatment facilities.

Maintenance and Maintenance

In order to ensure the long-term and stable operation of the Seepex BN70-18L stator, regular maintenance and maintenance are essential. Here are some maintenance suggestions:

- Regular Inspection

Perform a comprehensive inspection of the stator regularly, paying attention to wear and corrosion. If any abnormality is found, it should be replaced or repaired in time to avoid greater losses and failures.

- Cleaning and maintenance

During use, clean the stator regularly, especially when handling liquids that are easy to precipitate. Keeping the stator clean can not only improve the efficiency of the pump, but also extend its service life.

- Lubrication management

Regularly check the status of the lubricating oil to ensure that the lubricating oil is sufficient and clean. Good lubrication can reduce friction, improve work efficiency, and reduce energy consumption, thereby ensuring the stable operation of the equipment.

people also ask

Fill up and submit the below inquiry form, or directly write us an email: info@pumpvv.com