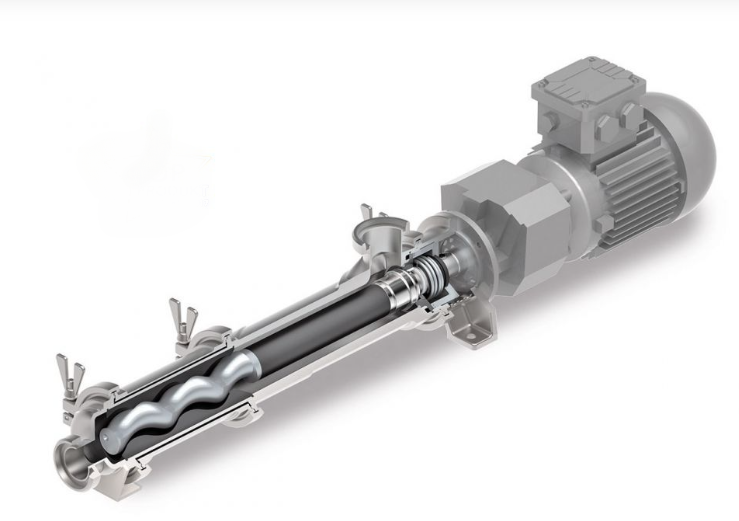

What is a stator?

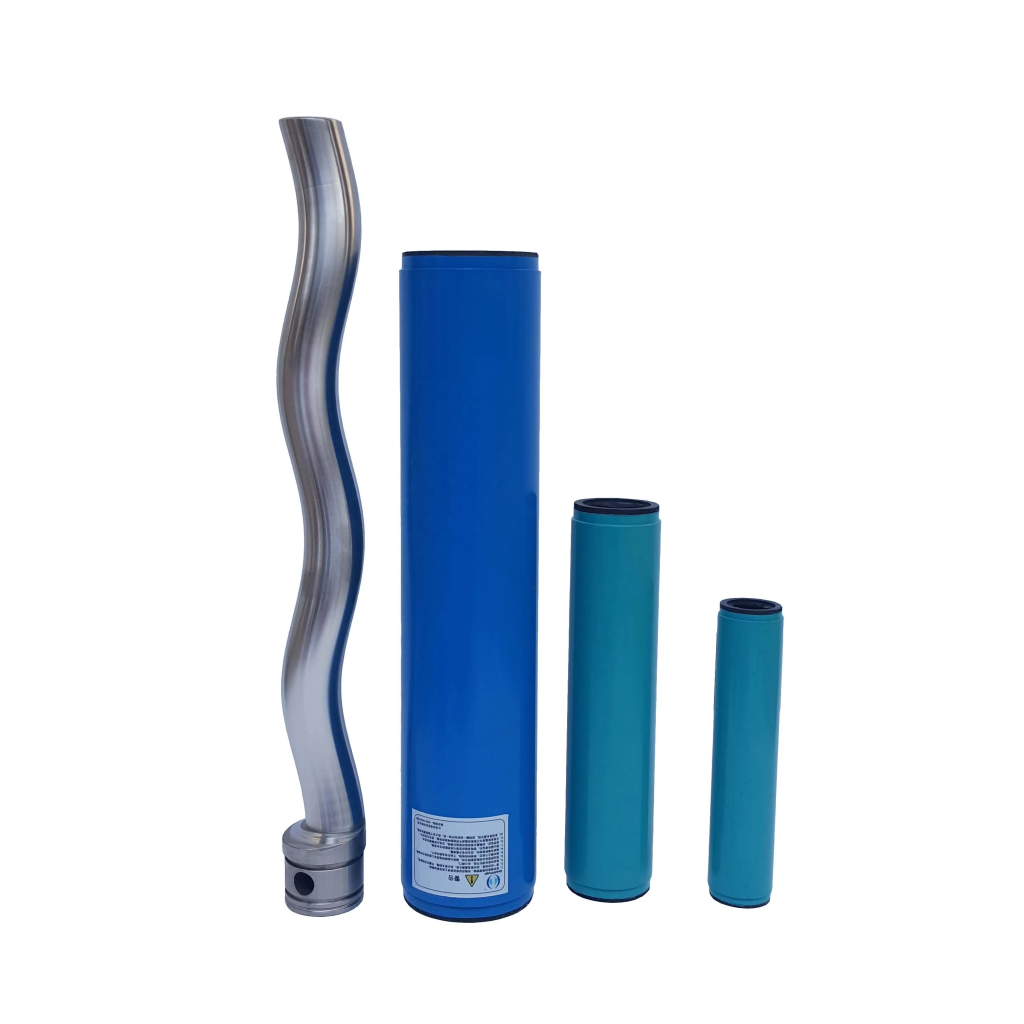

The stator of a screw pump is one of the core components of a screw pump. It consists of a stator core and a stator sleeve. The stator core is made of cast iron or steel plate, and has a certain rigidity and strength to support the work of the stator sleeve and the screw. The stator sleeve is made of rubber, polytetrafluoroethylene and other materials, and has good wear resistance and sealing performance.

Main features of BN75-6L stator

- Efficient fluid delivery

The BN75-6L stator adopts advanced materials and design to ensure efficient flow of fluid in the pump. Its unique geometry and surface treatment technology reduce friction and energy loss of the fluid, thereby improving the overall efficiency of the pump.

- Superior durability

Seepex’s stator has been rigorously tested and has excellent wear resistance and corrosion resistance. This enables the BN75-6L to work for a long time in harsh environments, reducing the frequency of maintenance and replacement, and reducing operating costs.

- Flexible adaptability

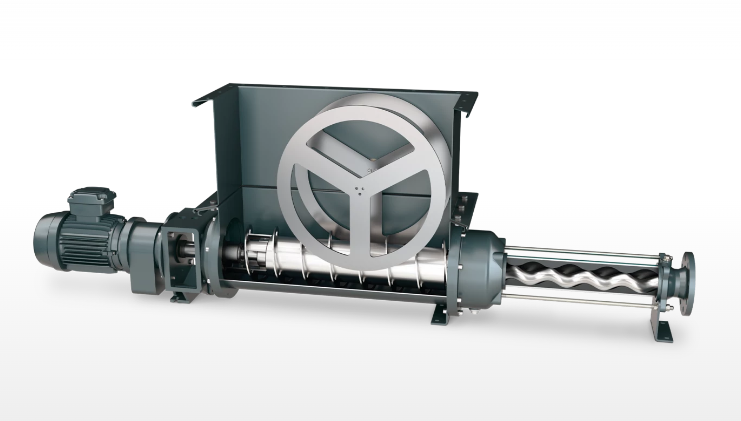

The BN75-6L stator is widely used in a variety of industries, including food processing, chemical industry and sewage treatment. Its design enables the stator to handle different types of fluids, including viscous, granular and corrosive fluids, showing extremely high adaptability.

Application areas

In the food industry, the BN75-6L stator is widely used in juice delivery and dairy processing. Its efficient fluid transmission ability can ensure product quality and avoid material damage during transportation.

In the chemical industry, the corrosion resistance of the BN75-6L stator enables it to safely handle a variety of chemicals and reduce environmental risks. At the same time, its wear resistance ensures long-term reliability.

Maintenance and care

In order to ensure the optimal performance of the BN75-6L stator, regular maintenance and care are essential. Here are some maintenance precautions:

- Regular inspection

Regularly check the wear of the stator to detect potential problems in time. Pay attention to the appearance of the stator to ensure that there are no obvious cracks or deformations.

- Cleaning

Keep the stator clean and avoid the accumulation of dirt and impurities. This will not only help extend the life of the stator, but also improve the efficiency of the pump.

- Lubrication

Regularly lubricate the stator according to the manufacturer’s recommendations to ensure smooth and stable operation. Proper lubrication can reduce friction and extend the life of the equipment.

people also ask

Send Your Enquiry :