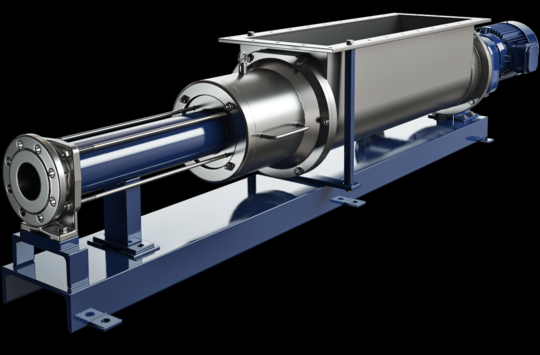

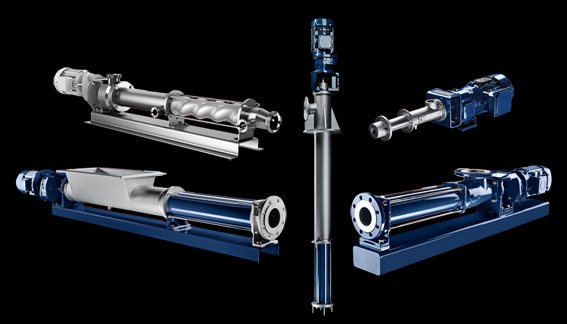

BN52-12L seepex BN

Technical parameters Pump shaft position: Horizontal Suction diameter: DN100 (mm) Power: 7.5kW Model: BN52-12 Conveying medium: Clean water pump Speed: 276 (rpm) Weight: 100kg Material: Cast iron Performance: Wear-resistant Lift: 60m Output flow: 200 Application: Chemical pump Drive mode: Electric Flow rate: 10-60 (m3/h) Efficiency: 98% Working temperature: Normal temperature Brand: SEEPEX Number of impellers:…