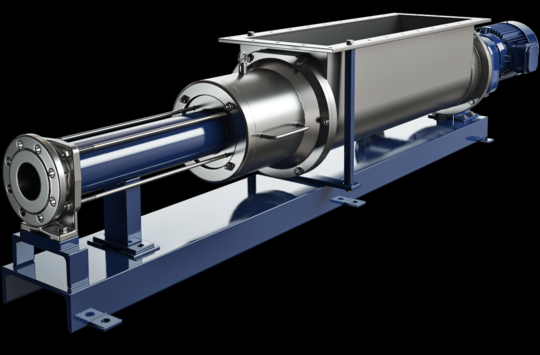

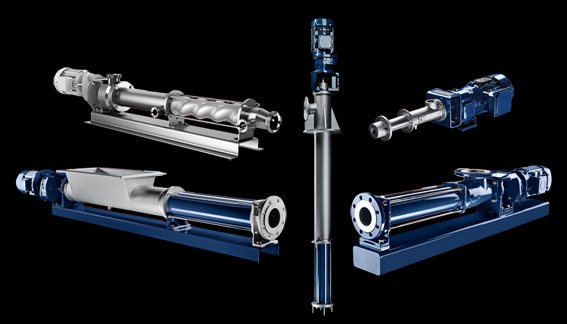

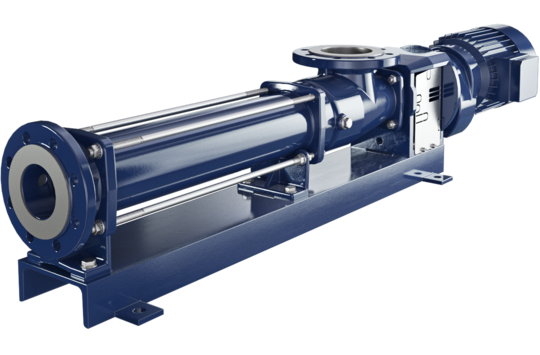

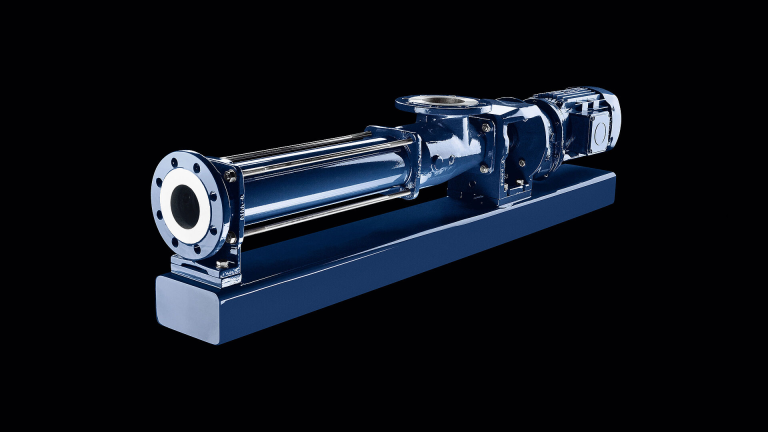

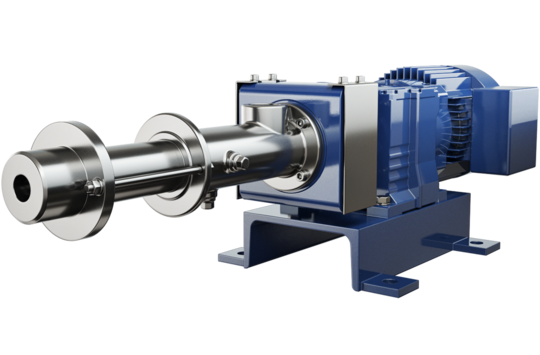

BN100-6L seepex BN

Parameters Introduction The rotor is the core component of seepex BN100-6L, responsible for driving the flow of fluid. Its design uses high-strength alloy materials with excellent wear resistance and corrosion resistance. In contrast to the rotor, the stator is the fixed part of the seepex BN100-6L, providing an excellent flow channel for the fluid. The…