Overview

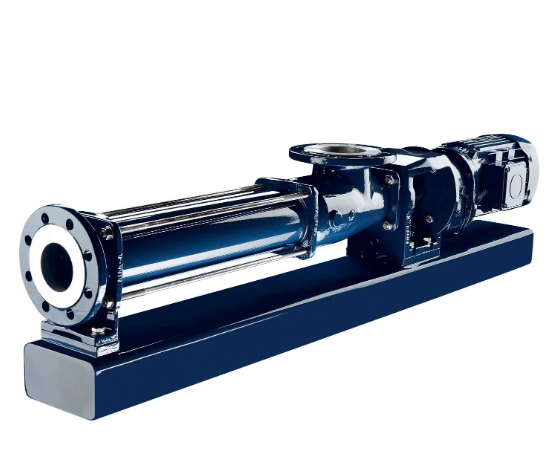

seepex BN70-12L adopts an advanced modular design, and uses detachable parts for quick and easy maintenance and repair. Daily maintenance can be completed without disassembling the entire pump body, greatly improving the service life and operating efficiency of the pump.

The pump body is made of corrosion-resistant materials, which can not only withstand harsh working environments, but also ensure the hygienic safety of the fluid delivery process. At the same time, the sealing system inside the pump has also been carefully designed to minimize the risk of leakage and contamination.

Parameters

| Performance: high pressure, stable | Brand: SEEPEX |

| Model: BN70-12 | Specifications: BN70-12 |

| Transport medium: sewage pump, impurity pump | Pressure: 1.2Mpa |

| Scope of application: sludge and sewage | Application: sewage pump |

| Drive mode: electric | Product features: no pulsation |

| Voltage: 380V | Speed: 200RPM |

| Pump shaft position: horizontal | Weight: 256kg |

| Material: cast steel | Impeller suction mode: single suction |

| Working pressure: 1.2MPa | Impeller structure: single impeller |

| Flow rate: 18m³/h | Lift: 120m |

Technical features

seepex BN70-12L adopts a number of advanced technologies to greatly improve the performance of the pump. Mainly including:

High-efficiency and low-noise screw design: The unique screw and rotor shape not only improves the efficiency of the pump, but also reduces noise and vibration.

Flexible rotor material selection: According to different application scenarios, rotors of different materials, such as stainless steel, ceramic, etc., can be selected to meet various working conditions.

Intelligent pressure monitoring system: Built-in high-precision pressure sensor, real-time monitoring of working pressure, helps prevent overpressure accidents.

Removable sealing system: With modular design, seals can be quickly replaced, greatly shortening maintenance time.

Wear-resistant and anti-corrosion materials: The pump housing and rotor are made of high-quality wear-resistant and corrosion-resistant materials with longer service life.

The seepex BN70-12L uses an advanced rotor and stator design. The seepex BN70-12L rotor is made of wear-resistant materials and can withstand long-term high-speed rotation without excessive wear. The seepex BN70-12L stator adopts a special spiral cavity design to effectively prevent the medium from accumulating inside. This unique rotor-stator combination ensures that the pump can maintain stable and efficient operation under various working conditions.

Application areas

With excellent performance and excellent design, seepex BN70-12L is widely used in various industrial fields. Mainly including:

- Chemical industry: conveying various corrosive chemicals, such as acid, alkali, etc.

- Papermaking industry: conveying pulp, filler slurry, etc.

- Food and beverage industry: conveying various viscous liquids, such as syrup, juice, etc.

- Pharmaceutical industry: conveying various pharmaceutical raw materials and intermediate products.

- Mining industry: conveying sludge, slurry, etc.

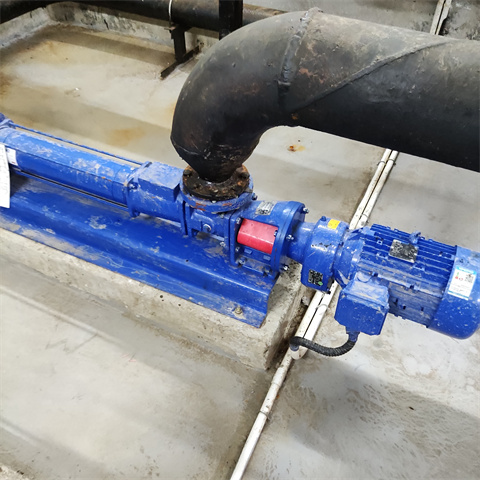

- Environmental protection industry: conveying sewage and sludge containing solid particles.

Product advantages

Compared with traditional industrial pumps, seepex BN70-12L stands out with the following advantages:

High efficiency and energy saving: The optimized flow channel design and high-efficiency and low-noise screw make the pump's energy consumption significantly lower than similar products.

Long service life: Wear-resistant and corrosion-resistant materials, as well as a detachable sealing system, greatly extend the service life of the pump.

Convenient maintenance: The modular design makes daily inspection and maintenance simple and fast, reducing maintenance costs.

Strong adaptability: The appropriate rotor material can be selected according to different application scenarios to meet various working conditions.

Safe and reliable: The intelligent pressure monitoring system can prevent overpressure accidents in time and improve operational safety.

people also ask

Fill up and submit the below inquiry form, or directly write us an email: info@pumpvv.com