[wpseo_breadcrumb]

Introduction

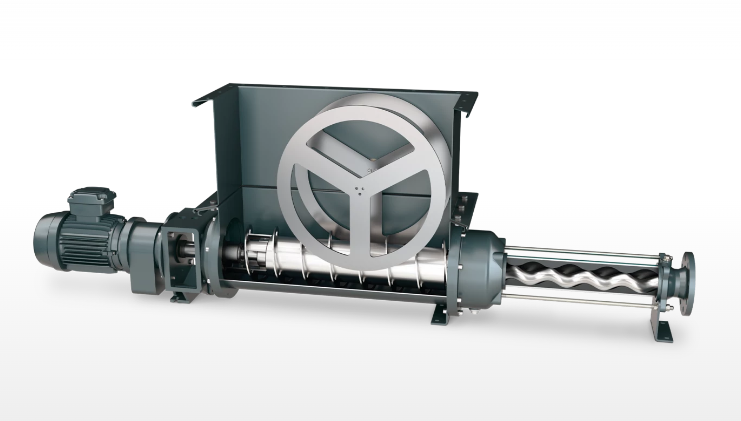

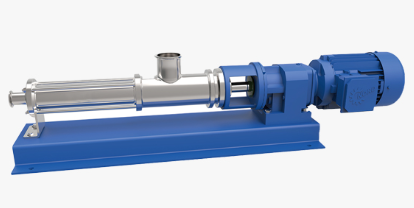

Low volume progressive cavity pumps are essential devices in various industries, serving unique functions that cater to the needs of specific applications. These pumps are known for their ability to handle viscous fluids and deliver precise flow rates, making them invaluable in sectors such as food processing, wastewater management, and chemical manufacturing.

How They Work

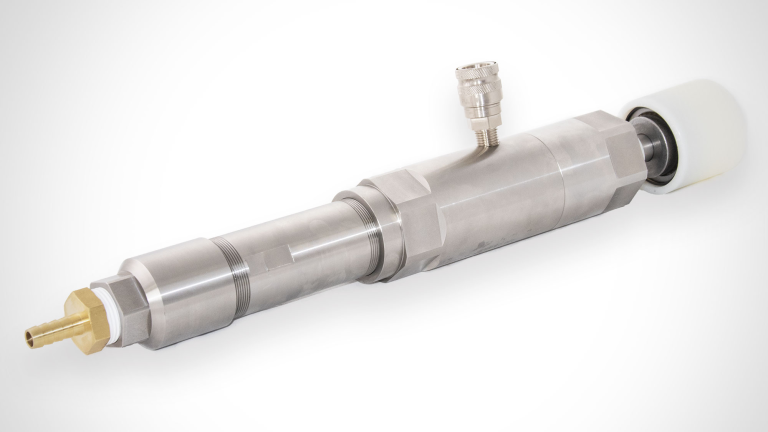

Progressive cavity pumps operate using a helical rotor that rotates within a stator. This unique design creates cavities that progressively move the fluid from the inlet to the outlet. The following points highlight the main features of these pumps:

- Positive Displacement: They move a consistent volume of fluid with each rotation, offering reliable flow rates.

- Smooth Flow: The design ensures a continuous and smooth flow, reducing pulsation and increasing efficiency.

- Self-Priming: These pumps can handle low suction pressures, making them effective for various applications.

Advantages

Low volume progressive cavity pumps offer several benefits that make them suitable for demanding environments. Here are some of the key advantages:

- Versatility: They can handle a wide range of fluids, including slurries, viscous liquids, and shear-sensitive materials.

- Durability: Constructed from robust materials, these pumps have a long operational life and can withstand harsh conditions.

- Low Maintenance: Their simple design minimizes wear and tear, leading to reduced maintenance efforts and costs.

Applications

Due to their unique characteristics, low volume progressive cavity pumps find applications in several industries, including:

- Food and Beverage: Used for transferring sauces, pastes, and other viscous products while maintaining product integrity.

- Wastewater Treatment: Ideal for handling sludge and other challenging materials in sewage systems.

- Chemical Processing: Employed in the transfer of chemicals, ensuring precise flow rates and safe handling.

Conclusion

In summary, low volume progressive cavity pumps play a crucial role in various industrial processes. Their ability to handle different types of fluids, combined with their efficiency and reliability, makes them a preferred choice for many applications. As industries continue to evolve, these pumps will remain integral to ensuring smooth operations and high-quality output.

People also ask

Send Your Enquiry :