[wpseo_breadcrumb]

Introduction

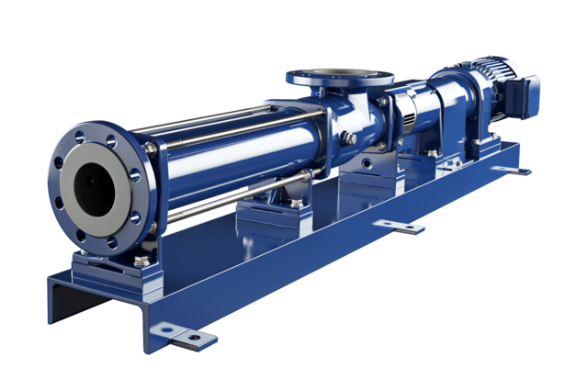

The low shear progressive cavity pump is an innovative solution designed for the efficient transfer of various types of fluids. This type of pump is especially favored in industries where maintaining the integrity of the fluid is crucial. Its unique design allows for gentle handling of shear-sensitive materials, making it an ideal choice for a wide range of applications.

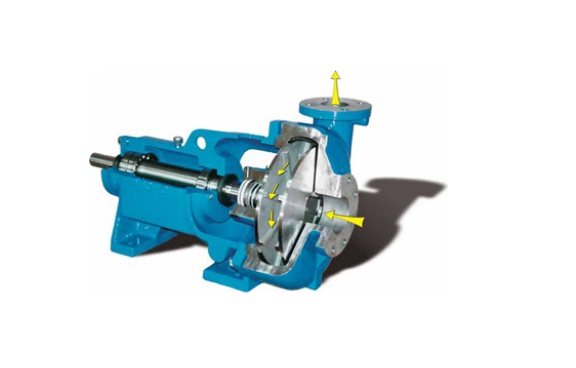

Working Principle

The progressive cavity pump operates on a simple yet effective principle. It consists of a helical rotor and a stator that work together to create a series of cavities. As the rotor turns, it moves the fluid through these cavities, ensuring a consistent flow. The design minimizes turbulence, which is vital for preserving the properties of sensitive fluids.

Key Components

- Helical Rotor: This component is responsible for moving the fluid through the pump. Its shape allows for smooth operation and minimal shear.

- Stator: The stator surrounds the rotor and creates the cavity that transports the fluid. It works in tandem with the rotor to ensure efficient fluid movement.

- Drive Unit: This component provides the necessary power to rotate the rotor, enabling the pump to function effectively.

Advantages

The low shear progressive cavity pump offers several benefits that make it an attractive option for various industries.

- Gentle Fluid Handling: The design of the pump ensures that fluids are moved without excessive shear, preserving their integrity and quality.

- Versatility: This pump can handle a wide range of viscosities, making it suitable for various applications, including wastewater treatment, food processing, and chemical manufacturing.

- Self-Priming Capability: The pump is capable of self-priming, which allows for easy operation and reduced downtime.

- Consistent Flow Rate: The progressive cavity design provides a steady flow rate, which is essential for processes that require precision.

Applications

Low shear progressive cavity pumps are utilized across multiple industries due to their unique benefits. Some common applications include:

- Food and Beverage Industry: Ideal for transferring delicate products like creams, sauces, and other shear-sensitive materials.

- Chemical Processing: Used for moving viscous chemicals and slurries without damaging their structure.

- Wastewater Treatment: Effective in handling sludge and other challenging materials typically found in wastewater.

- Pharmaceuticals: Ensures the safe transfer of sensitive compounds and formulations.

Conclusion

The low shear progressive cavity pump stands out as a reliable and efficient solution for fluid transfer in various industries. Its ability to handle shear-sensitive materials without compromising their integrity makes it a preferred choice for many applications. As technology continues to advance, the importance of such pumps in maintaining product quality and operational efficiency will only grow.

People also ask

Send Your Enquiry :