The Description of Pump Hopper

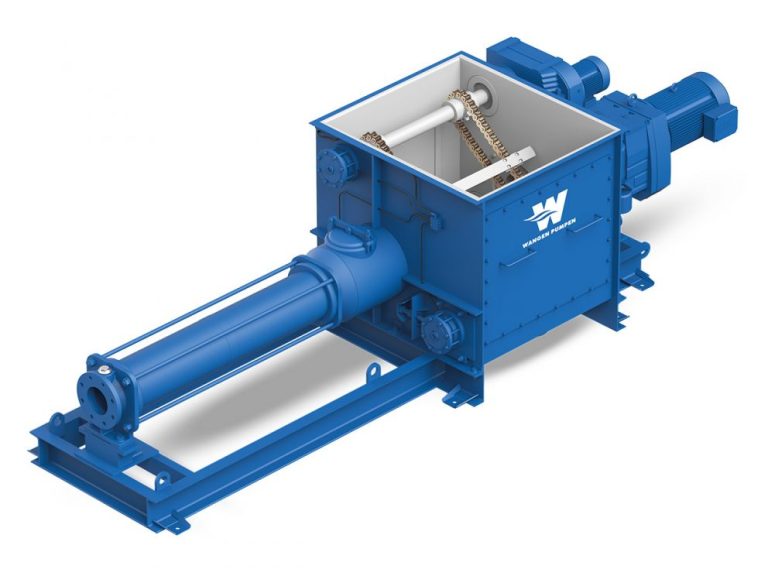

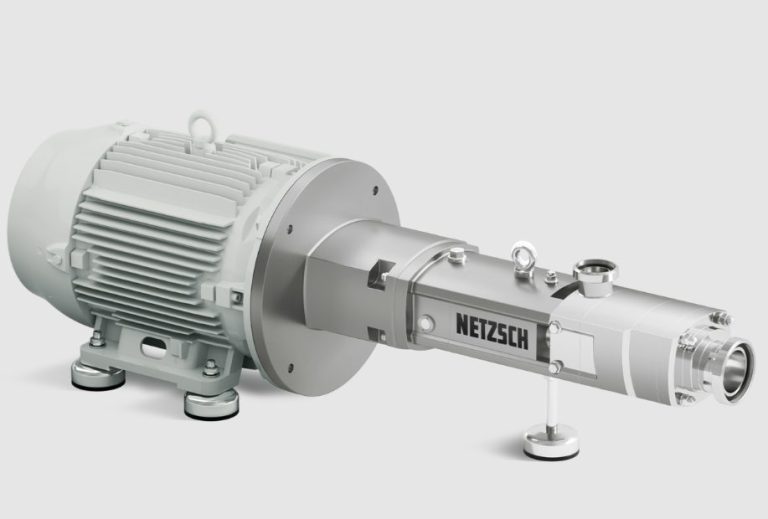

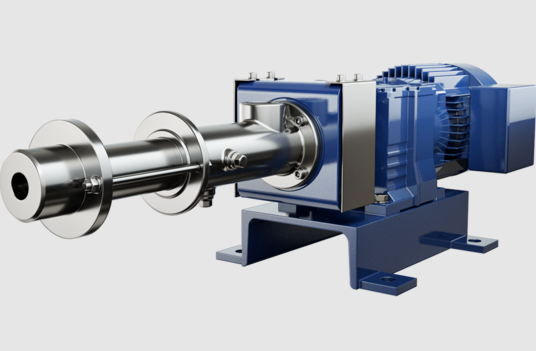

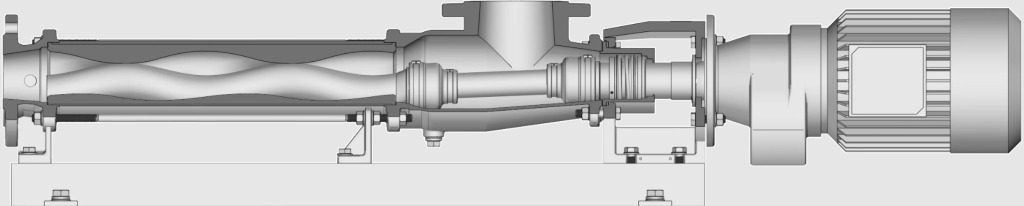

A pump hopper is an equipment used in the process of transferring materials from one location to another using a pump. It is designed to receive, store and feed material into the pump system efficiently and safely.

The Application of Pump Hopper

Pump hoppers are widely used in various industries such as agriculture, food processing, chemical manufacturing, and construction. They are particularly useful in situations where the material being transferred needs to be stored temporarily before being pumped to its final destination.

The Features of Pump Hopper

Efficient Material Handling: The pump hopper enables efficient storage and handling of material, ensuring smooth and uninterrupted pumping operations.

Improved Safety: With its enclosed design, the pump hopper ensures safe operation by minimizing the risk of spillage, contamination, and worker injury.

Versatile Design: Screw Pump hoppers are available in different sizes and configurations to suit various material handling requirements. They can be customized to fit specific pumps or integrated into existing systems.

Conclusion

Pump Hoppers are essential equipment for enhancing pumping efficiency and safety in various industries. With their versatile design and efficient material handling capabilities, they provide a reliable solution for storing and feeding materials into the pumping system.