BTQ – WITH RECTANGULAR HOPPER

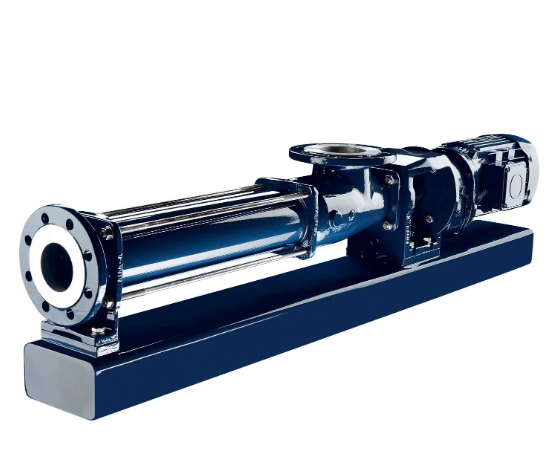

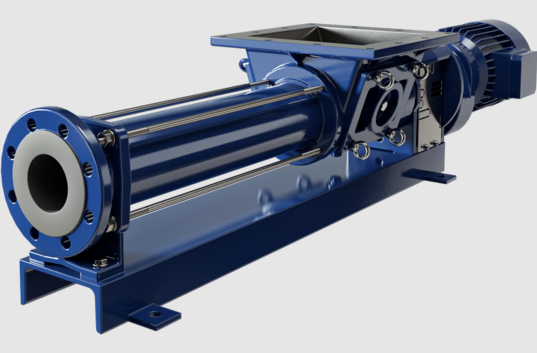

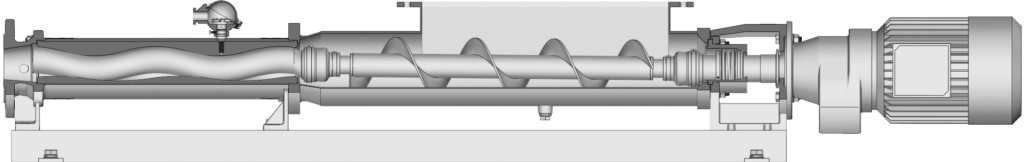

Rectangular upstream process systems require perfectly fitted hopper solutions. With its large rectangular hopper, the BTQ hopper pump from SEEPEX can easily be installed e.g. under thickeners in wastewater treatment plants. A screw conveyor on the coupling rod supports onward transport into the rotating unit. Alternatively, the coupling rod can also be fitted with mixing blades. As the dimensions of the BTQ hopper pump and the BN standard pump are identical, they are readily interchangeable.

The Description of BTQ – WITH RECTANGULAR HOPPER

The SEEPEX BTQ – WITH RECTANGULAR HOPPER is a specialized piece of equipment designed for the efficient handling of bulk materials. With its rectangular hopper design and high-quality stainless steel construction, it can handle a wide range of materials, including powders, granules, and pellets. Its unique discharge valve allows for precise control over flow rate, ensuring accurate batching and blending. Equipped with safety features like overload protection and automatic shut-off, the BTQ is a reliable and high-performance solution for handling bulk materials across various industries.

Application of BTQ – WITH RECTANGULAR HOPPER: Ideal for Bulk Material Handling

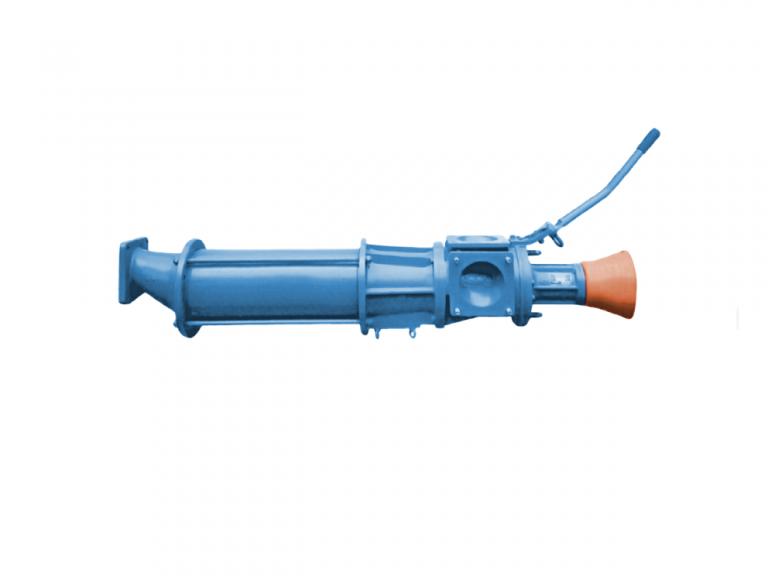

The BTQ – WITH RECTANGULAR HOPPER is a highly effective bulk material handling solution that is widely used in industries such as agriculture, mining, and construction. Its unique design combines a rectangular hopper with a belt conveyor to provide efficient and reliable material transfer.

This system is ideal for handling a wide variety of dry materials, including grains, sand, gravel, and minerals. Its rectangular hopper design allows for easy loading and reduces the risk of material bridging or jamming. The belt conveyor then ensures a steady flow of material to the desired destination.

Overall, the BTQ – WITH RECTANGULAR HOPPER is a versatile and efficient solution for any industry that requires bulk material handling.

Easy maintenance

Easy accessibility to the coupling rod and hopper through inspection ports mounted on the sides of the hopper

Optimum product conveyance

Optimal conveyance to the rotating unit by a very short screw conveyor installed on the coupling rod in the hopper – with optional mixing blades

Variable

Available in block design with directly flanged-on drive system, or as a variant with free bare shaft and plug connection

SCT retrofit option

Can be upgraded with a retrofit kit to use the particularly easy-to-maintain Smart Conveying Technology (SCT)

People Also Ask

Send Your Enquiry :