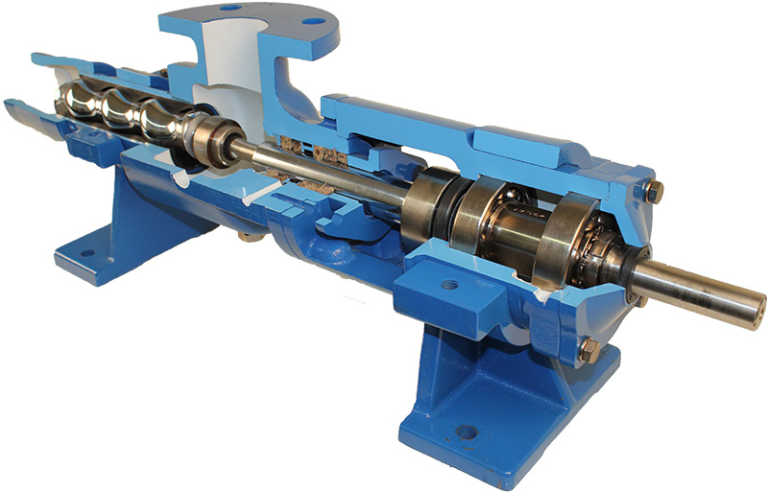

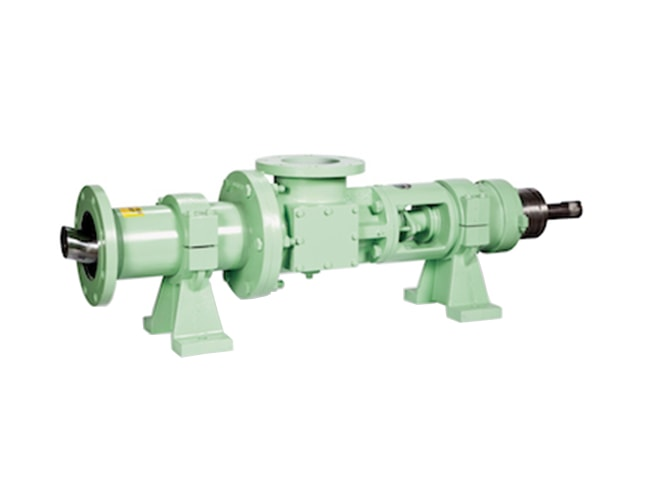

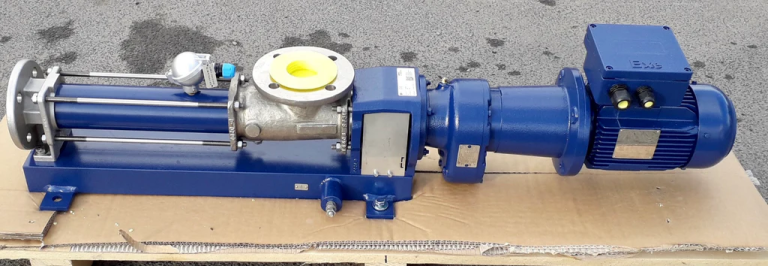

API 676 Progressive Cavity Pumps

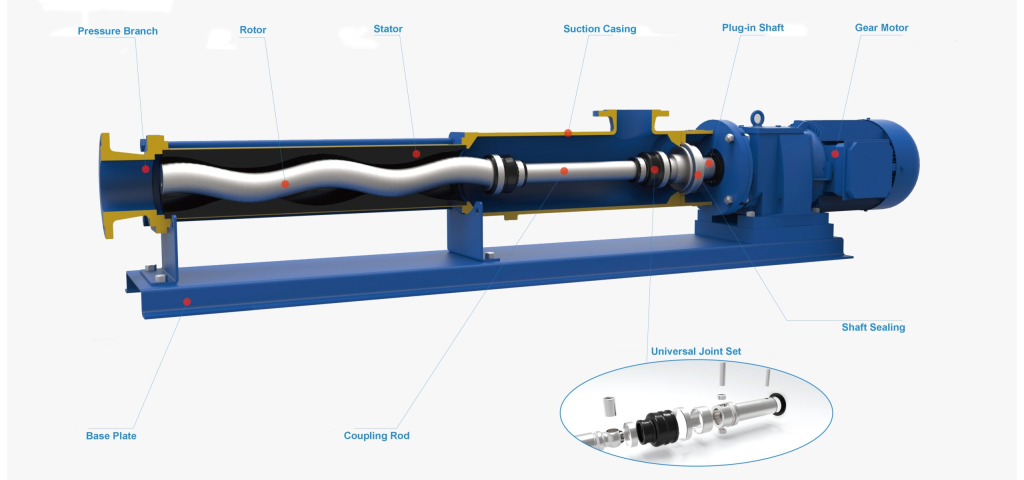

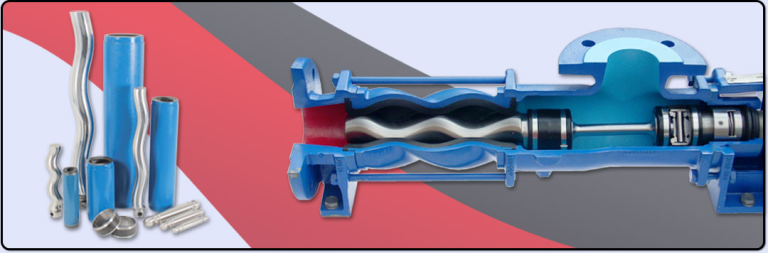

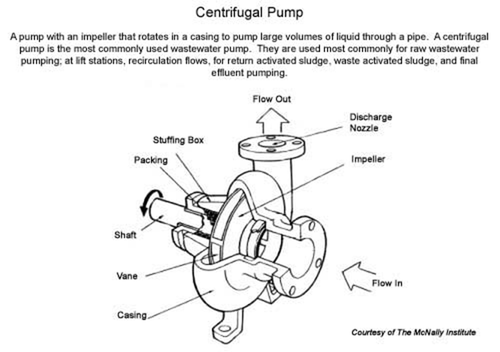

Progressive cavity pumps are widely used fluid transfer devices in various industrial sectors, particularly in oil, chemical, and food industries. Their unique structure and operating principles meet the demands of transporting complex fluids. This article explores the API 676 standard for progressive cavity pumps, including their features, applications, advantages and disadvantages, as well as maintenance…