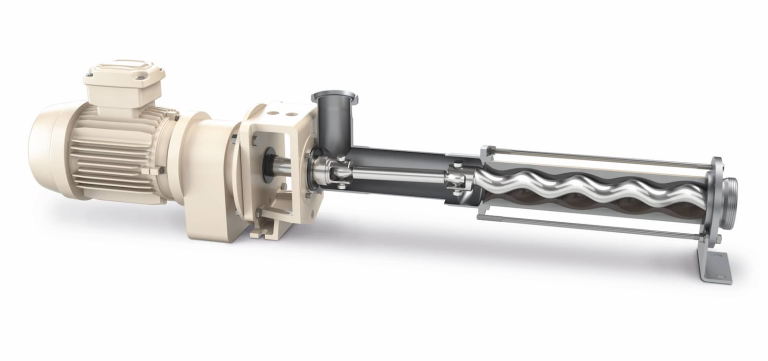

Progressing cavity pumps, often referred to as PC pumps, have gained significant attention in various industries due to their unique design and operational advantages. Liberty, a notable brand in this field, provides innovative solutions that cater to diverse applications. In this article, we will explore the features, benefits, and applications of Liberty progressing cavity pumps.

Understanding Progressing Cavity Pumps

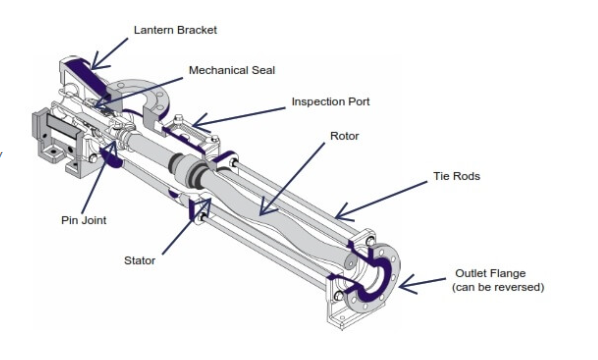

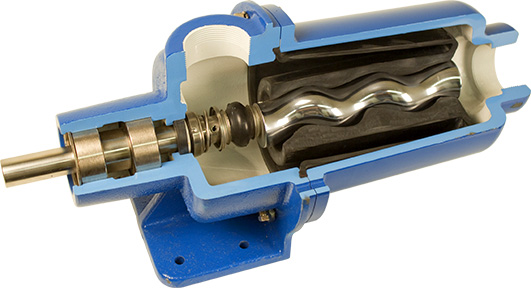

Progressing cavity pumps operate using a helical rotor that turns within a stator, creating a series of cavities that move fluid from the inlet to the outlet. This positive displacement mechanism allows for a consistent flow rate and makes these pumps suitable for handling viscous fluids.

Key Features of Liberty Progressing Cavity Pumps

- Versatility: These pumps can handle a wide range of fluids, including those with high viscosity and solids content.

- Low Shear: The design minimizes shear forces, making it ideal for sensitive materials that cannot be aerated or damaged.

- Continuous Flow: They provide a steady flow rate regardless of pressure changes, ensuring reliable performance in various conditions.

- Self-Priming: Liberty pumps can efficiently self-prime, reducing the need for additional equipment and simplifying installation.

- Durability: Constructed from high-quality materials, these pumps are designed for longevity, even in harsh environments.

Benefits of Using Liberty Progressing Cavity Pumps

- Efficiency: The design of Liberty pumps allows for energy-efficient operation, which can lead to cost savings over time.

- Low Maintenance: With fewer moving parts compared to traditional pumps, maintenance requirements are minimized, reducing downtime.

- Adaptability: Liberty pumps can be tailored to specific applications, offering customizable solutions that meet unique operational needs.

- Ease of Operation: The user-friendly design allows for straightforward operation and monitoring, making it accessible for personnel at all skill levels.

Applications of Liberty Progressing Cavity Pumps

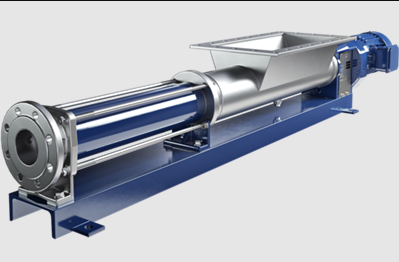

Liberty progressing cavity pumps have a wide range of applications across various industries, including:

- Oil and Gas: Used for transferring crude oil and other viscous fluids.

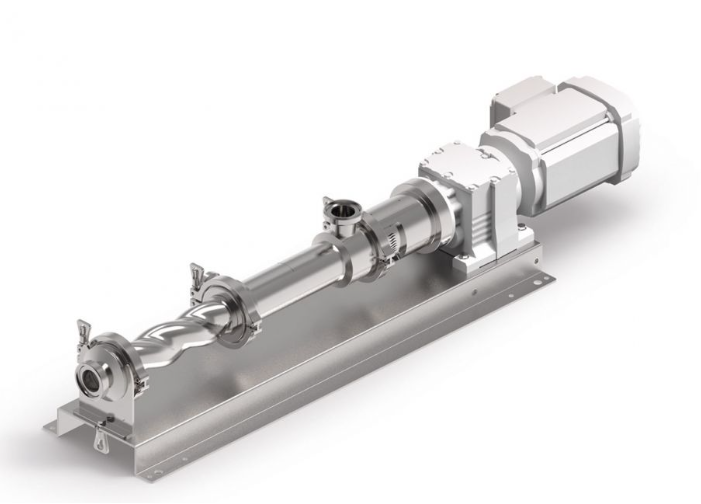

- Food and Beverage: Ideal for handling food products, sauces, and other sensitive materials.

- Chemical Processing: Suitable for transporting chemicals, slurries, and other industrial fluids.

- Wastewater Treatment: Effective in moving sludge and other byproducts in treatment facilities.

- Pharmaceuticals: Employed in the transfer of active ingredients and other critical materials.

Conclusion

Liberty progressing cavity pumps offer a reliable and efficient solution for a multitude of applications. Their unique design and operational advantages make them a preferred choice in industries that require the handling of challenging fluids. By investing in Liberty’s innovative pump technology, businesses can enhance productivity, reduce maintenance costs, and ensure the smooth operation of their processes. Whether in oil and gas, food processing, or wastewater management, Liberty progressing cavity pumps stand out as a testament to modern engineering and design excellence.

Send Your Enquiry :