Introduction

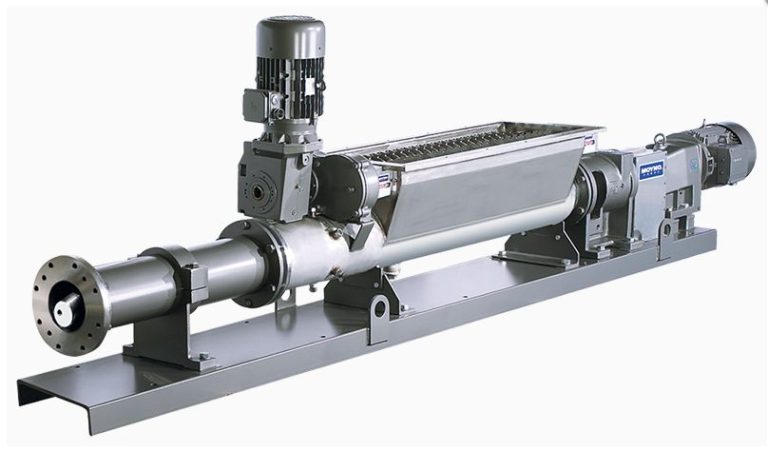

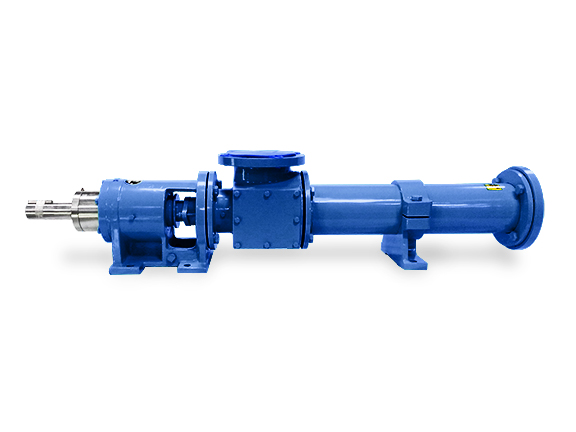

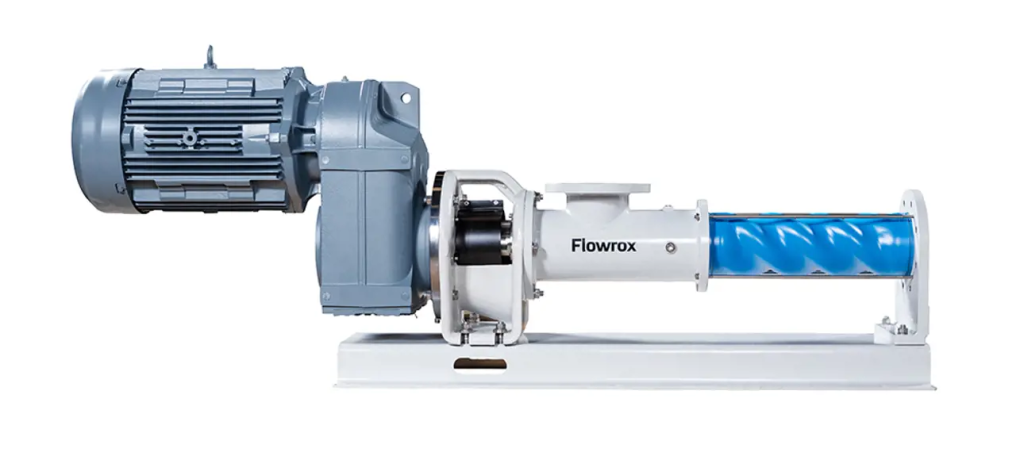

Progressive cavity pumps are widely used in various industries due to their ability to handle viscous fluids and provide a steady flow. Among these pumps, low cost progressive cavity pumps have gained popularity for their affordability and efficiency. This article explores the features, advantages, and applications of low cost progressive cavity pumps.

Features of Low Cost Progressive Cavity Pumps

Low cost progressive cavity pumps come with several key features that make them an attractive option for many applications:

- Simple Design: These pumps have a straightforward design that allows for easy manufacturing and maintenance.

- Versatile Material Options: They can be constructed using various materials, making them suitable for different fluid types and conditions.

- Compact Size: Their compact design allows for installation in tight spaces without compromising performance.

- Low Maintenance Requirements: With fewer moving parts, these pumps generally require less maintenance compared to other types.

Advantages of Low Cost Progressive Cavity Pumps

Choosing a low cost progressive cavity pump offers numerous benefits:

- Cost-Effectiveness: The initial investment is lower, making them accessible for small to medium-sized businesses.

- Energy Efficiency: These pumps often consume less energy, leading to reduced operational costs over time.

- Reliable Performance: They provide a consistent flow rate, ensuring reliable operation across various applications.

- Adaptability: Low cost progressive cavity pumps can handle a wide range of viscosities and fluid types, making them versatile in different settings.

Applications of Low Cost Progressive Cavity Pumps

Low cost progressive cavity pumps are utilized in various industries, including:

- Food and Beverage: Ideal for transferring viscous liquids like sauces, syrups, and pastes without damaging the product.

- Wastewater Treatment: Effective for pumping sludge and other thick fluids in treatment plants.

- Chemical Processing: Suitable for handling corrosive and abrasive materials, thanks to their durable construction.

- Oil and Gas: Used for transferring crude oil and other petroleum products due to their robustness.

Conclusion

Low cost progressive cavity pumps offer a practical solution for industries looking to optimize fluid transfer processes without breaking the bank. Their simple design, energy efficiency, and versatility make them a valuable addition to various applications. As businesses continue to seek ways to enhance productivity while managing costs, low cost progressive cavity pumps are likely to remain a popular choice in the market.

People also ask

Send Your Enquiry :