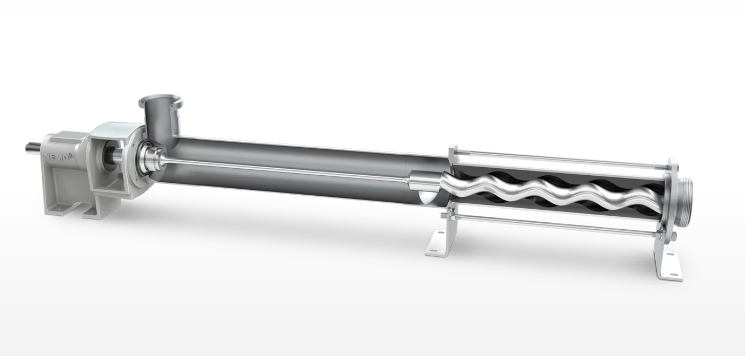

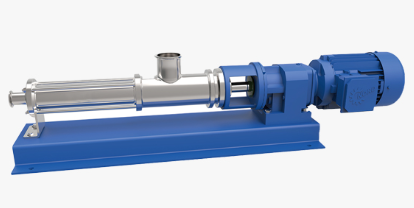

Progressive cavity pumps, specifically those manufactured by Moyno, are renowned for their efficiency and reliability in various industrial applications. Understanding the pump curves associated with these devices is essential for optimizing performance and achieving desired outcomes in fluid handling systems. This article will delve into the significance of Moyno progressive cavity pump curves, their features, and how to interpret them effectively.

Understanding Pump Curves

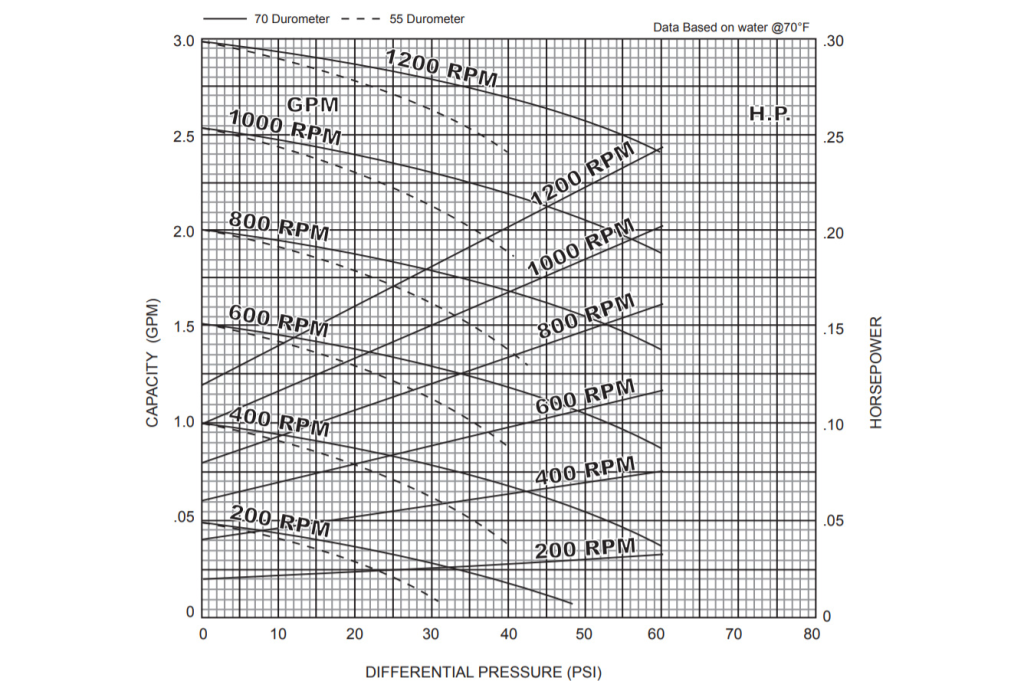

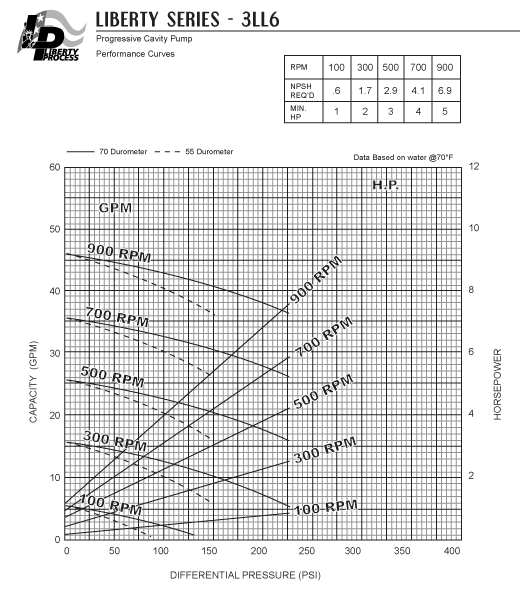

Pump curves are graphical representations that illustrate the relationship between flow rate and pressure for a specific pump model. They provide critical insights into how the pump will perform under varying conditions. For Moyno progressive cavity pumps, these curves are particularly useful for:

- Identifying Operating Points: The curves help users determine the optimal operating point for their specific application.

- Evaluating Performance: Users can assess the pump’s efficiency across different flow rates and pressures.

- Selecting the Right Pump: When comparing different models, pump curves can guide users in selecting the most suitable option for their needs.

Key Features of Moyno Pump Curves

Moyno progressive cavity pump curves exhibit several key characteristics that are important for users to understand:

- Flow Rate vs. Pressure: The primary feature of the curve, showing how flow rate changes concerning discharge pressure.

- Efficiency Zones: Areas on the curve indicate where the pump operates most efficiently, allowing for better energy management.

- NPSH Requirements: The curves often include information on Net Positive Suction Head (NPSH), which is critical for preventing cavitation.

Interpreting the Curves

To effectively utilize Moyno pump curves, users should follow these steps:

- Identify the Application Requirements: Understand the specific needs of the application, including flow rate and pressure.

- Locate the Operating Point: Use the pump curves to find the intersection of the desired flow rate and pressure.

- Evaluate Efficiency: Check whether the identified operating point falls within the efficiency zones of the curve.

- Consider NPSH: Ensure that the NPSH available in the system meets the requirements indicated on the pump curve to avoid operational issues.

Conclusion

Moyno progressive cavity pump curves are invaluable tools for engineers and operators in the field. By understanding how to read and interpret these curves, users can make informed decisions that enhance the performance and reliability of their fluid handling systems. Whether selecting a new pump or optimizing an existing system, familiarity with these curves is essential for achieving operational excellence.

Send Your Enquiry :