Parameters

- Voltage: 380V

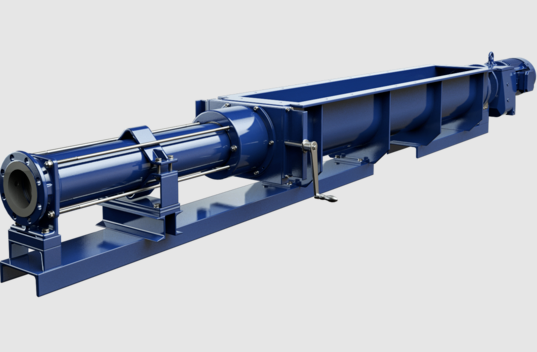

- Pump shaft position: horizontal

- Material: stainless steel

- Working pressure: 0.6MPa

- Flow rate: 50m³/h

- Drive mode: electric

- Scope of application: sludge and sewage

- Transport medium: sewage pump, impurity pump

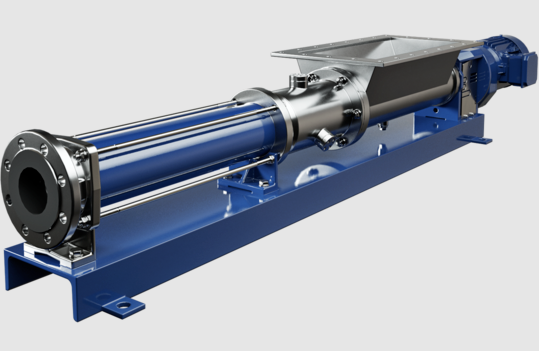

- Model: BN100-6L

- Lift: 60m

- Impeller structure: single impeller

- Weight: 180kg

- Speed: 180RPM

- Product features: no pulsation

- Application: sewage pump

- Pressure: 0.6Mpa

- Brand: SEEPEX

Introduction

The rotor is the core component of seepex BN100-6L, responsible for driving the flow of fluid. Its design uses high-strength alloy materials with excellent wear resistance and corrosion resistance. In contrast to the rotor, the stator is the fixed part of the seepex BN100-6L, providing an excellent flow channel for the fluid.

The stator is usually made of high-performance rubber materials to reduce friction losses and improve the overall efficiency of the pump.

The wide range of applications of seepex BN100-6L makes it the first choice for many industries. In the chemical industry, BN100-6L can handle a variety of corrosive and viscous liquids, providing strong support for production.

In the environmental protection industry, BN100-6L can efficiently transport sewage and wastewater, help treat various types of sewage, and ensure compliance with environmental standards. In sewage treatment plants, pumps are responsible for transporting sewage to treatment facilities to ensure smooth flow.

Although the seepex BN100-6L has a sturdy structure, regular maintenance cannot be ignored. Regularly checking the wear of the rotor and stator and replacing worn parts in time will help extend the service life of the pump.

people also ask

Send Your Enquiry :