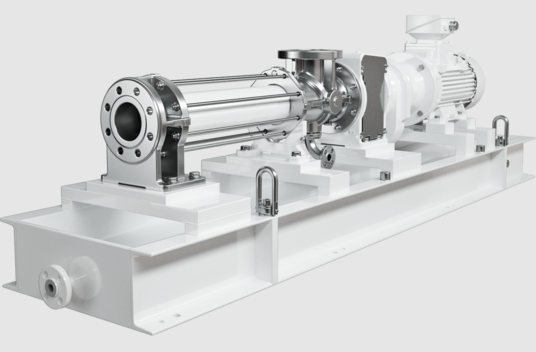

MD0005-24 stator seepex

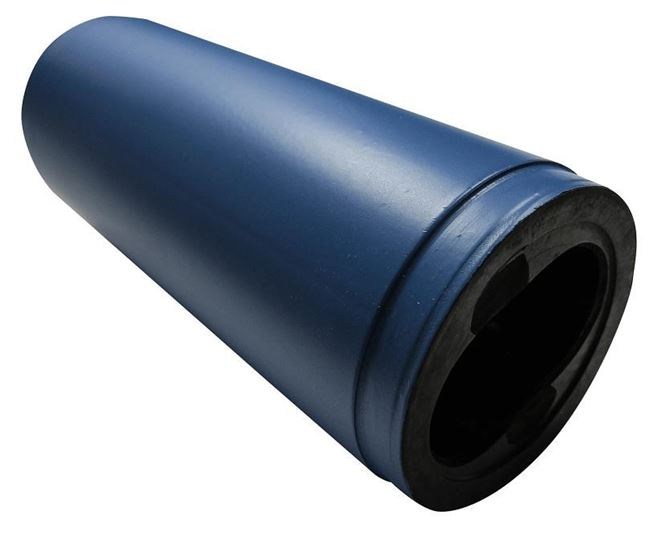

The main function of the Seepex MD0005-24 stator is to work with the screw rotor to form a powerful closed conveying space. This structure can effectively handle various viscous and non-flowing fluids, ensuring the smoothness and continuity of the fluid during the conveying process. Whether in the chemical, food, or pharmaceutical industries, the Seepex MD0005-24 stator can provide strong support to make fluid conveying more efficient.

Advantages

- Low energy consumption

- The optimized design makes it low in energy consumption during the conveying process, while ensuring efficient flow, it reduces the operating costs of the enterprise.

- Efficient fluid conveying

- The Seepex MD0005-24 stator cooperates with the rotor to form a closed conveying space, which effectively improves the conveying efficiency of the fluid, especially suitable for high-viscosity fluids.

- Strong durability

- Made of high-quality materials, it can resist corrosion and wear, extend service life, and reduce maintenance costs.

- Easy to maintain

- The design is simple, easy to disassemble and clean, and the maintenance process is fast, reducing downtime.

Features

| Installation process | The design takes into account the need for easy installation and can quickly adapt to different working environments. |

| Flexible and applicable | Suitable for a variety of working conditions and liquid types, can be configured according to different needs. |

| Stable operation | Maintain a stable output flow under a variety of fluid conditions to ensure the continuity of the production process. |

| Hygienic design | Meets the hygiene requirements of the food and pharmaceutical industries and can prevent fluid contamination during transportation. |

Application areas

- Food and beverages

- Suitable for the transportation of products such as juice, syrup, dairy products, etc., meeting strict hygiene standards.

- Coatings and plastics

- Efficiently transport various high-viscosity media in the production process of coatings and plastics.

- Pharmaceutical industry

- Used for high-viscosity liquid transportation in pharmaceutical production to ensure the purity and stable flow of drugs.

- Chemical industry

- Used for the transportation of various chemicals and viscous slurries to ensure the stability of chemical reactions.

- Wastewater treatment

- Treats wastewater and related solids to improve the efficiency of sewage treatment plants.

people also ask

Send Your Enquiry :