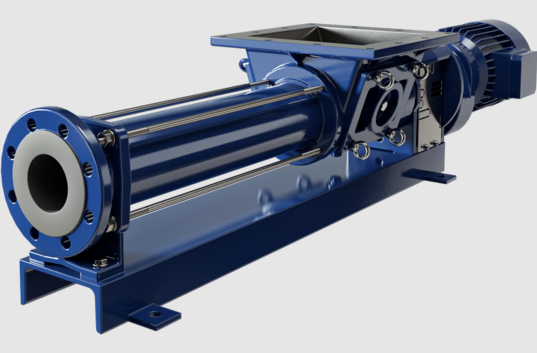

Technical Features of Seepex BN5-6L Stator

The Seepex BN5-6L stator is a highly efficient screw pump component designed specifically for conveying viscous and non-viscous fluids. Its main function is to work with the rotor to push the fluid from the feed port to the discharge port. Its special geometry and material selection enable the stator to maintain excellent performance under high pressure and high flow conditions.

The BN5-6L stator is usually made of highly wear-resistant rubber or polyurethane, which has excellent corrosion and wear resistance and can provide long-term reliability in different working environments. In addition, the design of the component also takes into account the problems of thermal expansion and temperature changes, ensuring stability under extreme conditions.

Application Areas

The Seepex BN5-6L stator is widely used in many industries, including:

- Chemical Industry: When handling chemicals, solvents and slurries, the corrosion and wear resistance of the stator ensures safe and stable operation.

- Sewage treatment: In sewage and wastewater treatment, this stator can effectively convey high-viscosity fluids, reducing pump clogging and maintenance frequency.

- Food processing: In the food industry, the hygienic design of the Seepex BN5-6L stator ensures food safety while providing efficient fluid delivery.

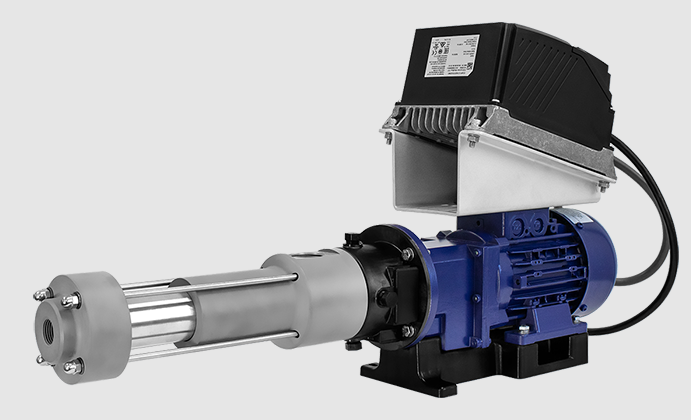

Performance advantages

- High efficiency and energy saving

Compared with traditional pumps, the Seepex BN5-6L stator is more compact and can provide higher flow rates with lower energy consumption. This efficiency not only helps to reduce energy costs, but also has a positive impact on environmental protection. - Strong adaptability

Whether conveying light liquids or high-viscosity fluids, the BN5-6L stator can maintain good performance. Its flexibility makes it an ideal choice for a variety of applications and users can customize it according to specific needs. - Easy maintenance

Seepex’s design concept emphasizes easy maintenance. The BN5-6L stator is relatively simple to replace and does not require complex tools or expertise, which greatly reduces user maintenance costs.

Choose the right stator

When choosing a Seepex BN5-6L stator, users need to consider the following factors:

| Fluid properties: Choose the right material and design according to the application to ensure the compatibility of the stator with the fluid. |

| Operating conditions: Determine at what temperature and pressure the stator operates to select the appropriate specifications. |

| Maintenance strategy: Consider the maintenance cycle and cost and choose a solution that suits you. |

people also ask

Send Your Enquiry :