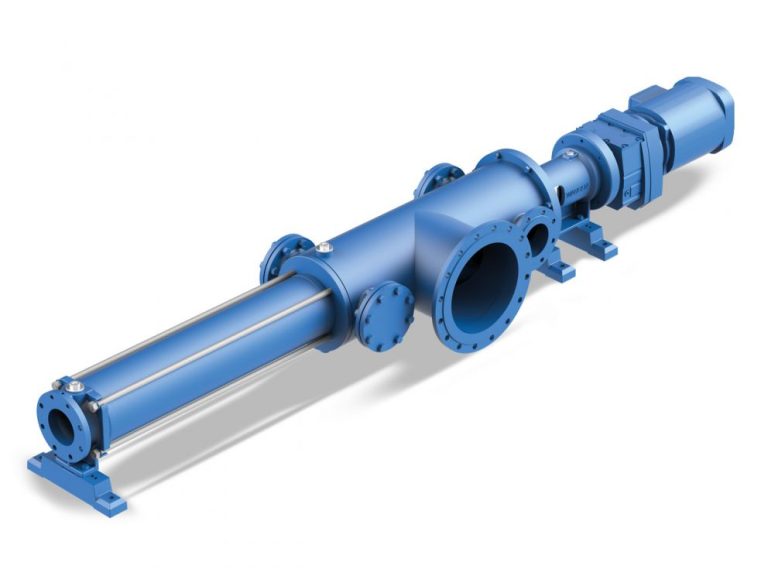

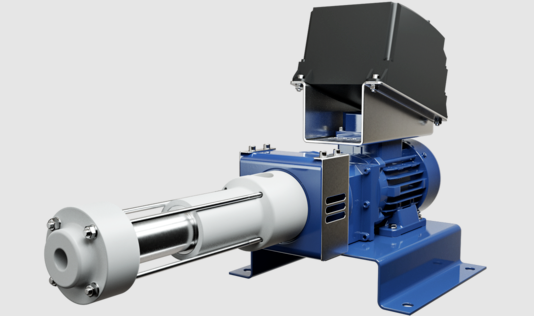

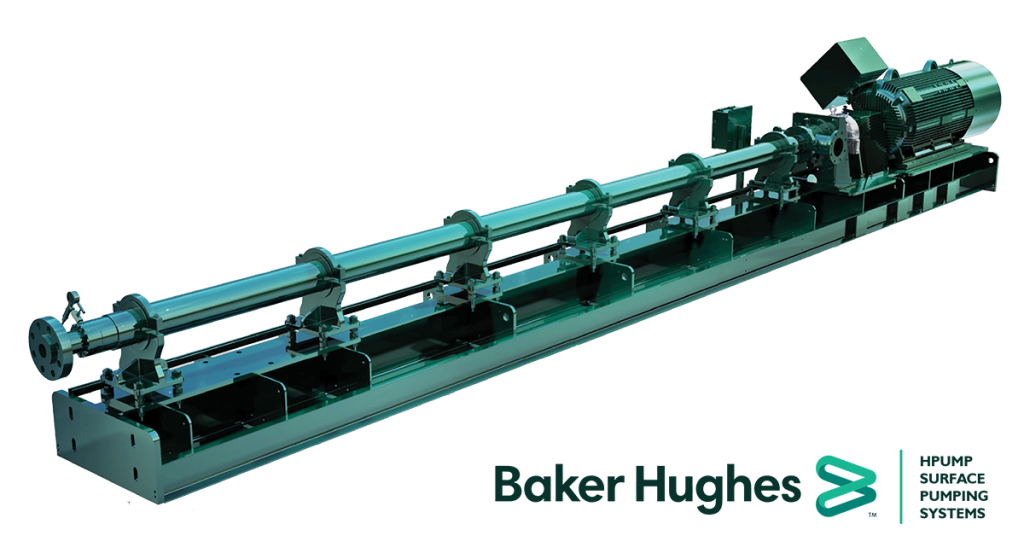

Working Principle of Progressive Cavity Pumps

The working principle of progressive cavity pumps is relatively simple yet highly efficient. They consist of a helical rotor and a stator. As the rotor rotates inside the stator, it creates multiple progressive cavities that transport fluid from the inlet to the outlet. This process can occur at lower pressures, making it suitable for pumping high-viscosity fluids.

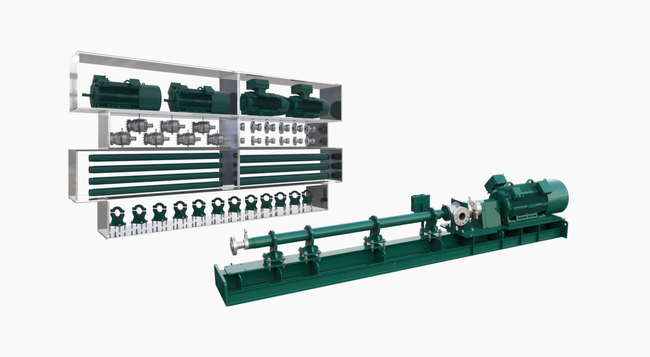

Main Components

- Rotor: Responsible for moving the liquid by generating suction through rotation.

- Stator: Provides a channel for fluid flow, typically made of elastic material to accommodate the rotor’s movement.

- Drive Mechanism: Transmits power to the rotor, ensuring continuous rotation.

Applications of Progressive Cavity Pumps

Baker Hughes’ progressive cavity pumps have widespread applications across various industries, including:

Oil and Gas Industry

In this sector, progressive cavity pumps are commonly used for:

- Extracting crude oil and natural gas

- Transporting high-viscosity fluids

- Handling liquids containing solid particles

Chemical Industry

The chemical industry requires handling diverse types of fluids, where progressive cavity pumps are applied for:

- Transporting chemical raw materials

- Processing viscous and corrosive liquids

- Mixing liquids in reactors

Food and Beverage Industry

In the food and beverage sector, safety and hygiene are paramount. Progressive cavity pumps can:

- Transport various food ingredients and beverages

- Ensure the integrity of fluids during transport

- Meet stringent hygiene standards

Environmental Industry

In the environmental sector, progressive cavity pumps are utilized for:

- Treating wastewater

- Transporting chemical agents

- Conducting water treatment and recycling

Advantages of Progressive Cavity Pumps

Baker Hughes’ progressive cavity pumps have several advantages that make them stand out in the market:

High Efficiency

- Capable of handling high-viscosity fluids with lower energy consumption.

- Adjustable flow rates to meet different operational needs.

Low Maintenance Costs

- Simple structure for easy maintenance, reducing downtime.

- Minimal wear on the stator and rotor, resulting in a longer lifespan.

Strong Adaptability

- Can handle various fluid types, including corrosive liquids and those containing solid particles.

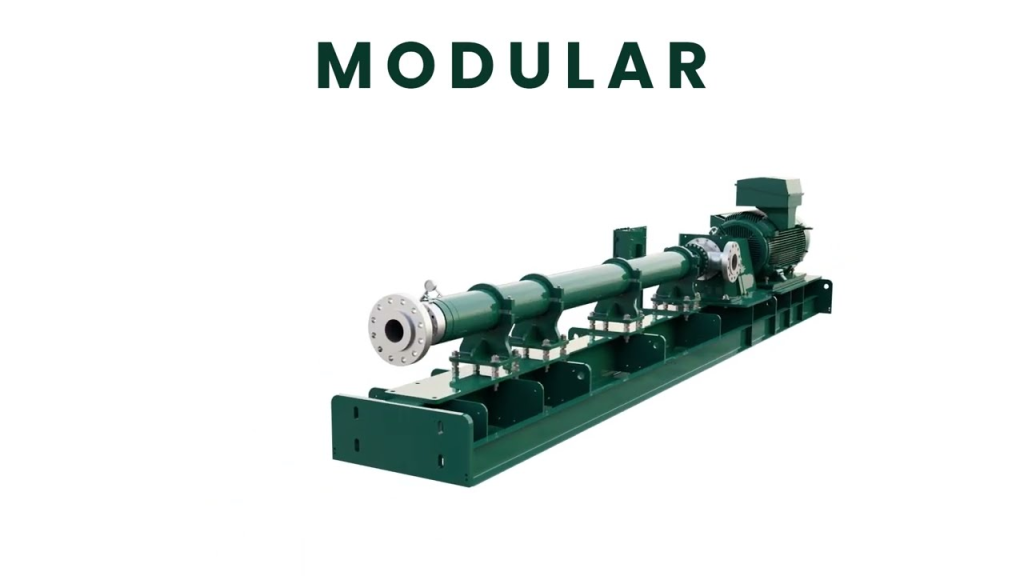

- Offers customized solutions based on different industry needs.

High Safety Standards

- Designed to minimize leakage risks, ensuring operational safety.

- Complies with industry standards to guarantee fluid safety during transport.

Conclusion

Baker Hughes’ progressive cavity pumps have become indispensable equipment across numerous industries due to their outstanding performance and versatility. Whether in oil and gas, chemical, food and beverage, or environmental sectors, these pumps demonstrate unique advantages. Through continuous technological innovation, Baker Hughes will continue to lead the development of progressive cavity pumps, providing customers with more efficient and safer solutions.

People also ask

Send Your Enquiry :