[wpseo_breadcrumb]

Moyno AugMentor Pump

The AugMentor® Pump Stuffer handles high-viscosity materials otherwise unpumpable by conventional means. Materials in excess of 1,000,000 cps, such as cold processed meats and bakery dough, are easily fed by the AugMentor’s slow-speed, bottom-drive auger.

The Description of Moyno AugMentor Pump

- Wastewater treatment: The Moyno Augmentor Pump can effectively move sludge and other thick, viscous materials commonly found in wastewater treatment facilities.

- Chemical processing: The pump’s ability to handle abrasive and corrosive materials makes it well-suited for use in chemical processing plants.

- Food processing: The Moyno Augmentor Pump is ideal for transferring food products that are sensitive to shear forces, such as dairy products and sauces.

- Oil and gas: The pump’s ability to handle high-viscosity fluids makes it well-suited for upstream and downstream oil and gas applications.

- Mining: The Moyno Pump is also commonly used in the mining industry, where it can effectively move abrasive and corrosive slurries.

The Application of Moyno AugMentor Pump

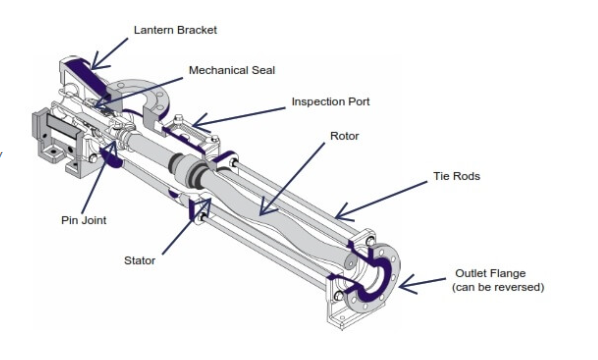

The Moyno AugMentor Pump is a highly efficient and reliable pumping solution. It combines the proven performance of Moyno’s progressive cavity pump technology with an integrated auger feed system. This innovative design ensures consistent and precise product handling, making it ideal for applications requiring accurate metering and gentle product transfer. The AugMentor Pump offers excellent suction capabilities, minimal pulsation, and low shear, making it suitable for a wide range of industries, including food processing, pharmaceuticals, and wastewater treatment.

Moyno AugMentor Pump Features

- The unique design of the AugMentor offers numerous performance enhancing features

- Low shear transfer with little smearing preserves product integrity

- Unobstructed, wide-open stuffer facilitates continuous positive feed of pumped material

- Hinged hopper permits easy clean-up and inspection

- Less costly to maintain than hydraulic feed systems

- 300 series stainless steel construction polished to a #4 finish for maximum corrosion resistance and cleaner sanitary surfaces

People Also Ask

Send Your Enquiry :