[wpseo_breadcrumb]

Description of Progressive Cavity Metering Pump

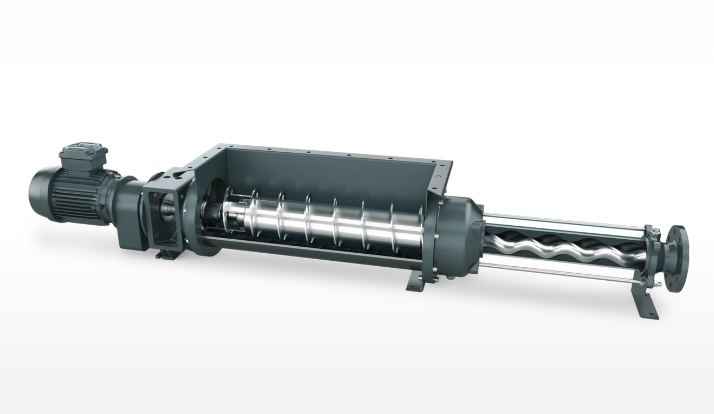

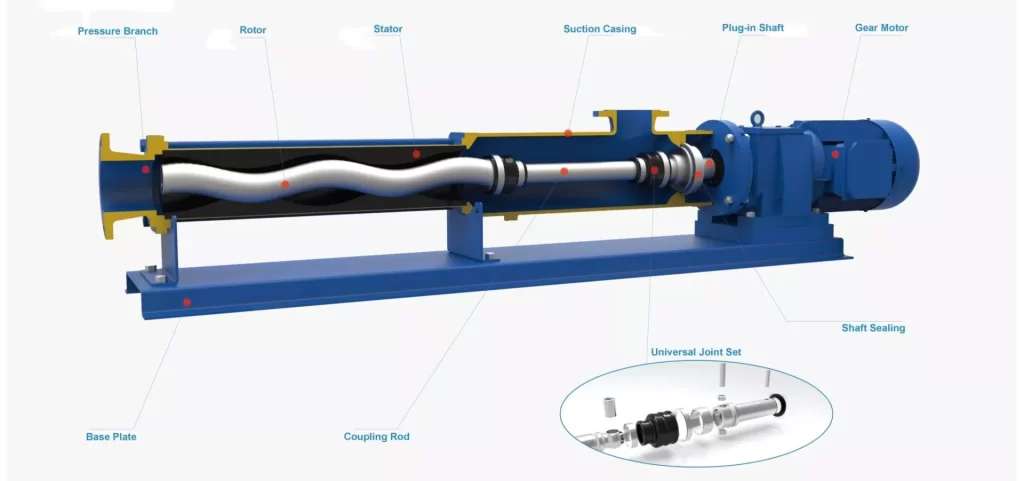

The Progressive Cavity Metering Pump is a precision-engineered fluid dispensing solution characterized by a helical rotor encased within a flexible elastomeric stator. This design ensures accurate and controlled pumping for various liquids, meeting the demands of industries requiring precision dosing.

Application of Progressive Cavity Metering Pump

Ideal for chemical dosing, food and beverage processing, and wastewater treatment, the Progressive Cavity Metering Pump excels in applications demanding precise fluid metering. Its versatility makes it a reliable choice across diverse industries.

Features of Progressive Cavity Metering Pump

Compact in design, with low pulsation and the ability to handle a broad viscosity range, this pump offers customizable flow rates for accurate fluid delivery. Its robust features make it well-suited for applications where consistent and controlled dosing is essential.

Benefits of Our Custom Manufacturing

Our custom manufacturing approach ensures that the Progressive Cavity Metering Pump aligns precisely with your specific requirements. This tailored production process guarantees optimal performance, reliability, and efficiency, meeting the unique needs of your application.

People Also Ask

Send Your Enquiry :