[wpseo_breadcrumb]

Description of SEEPEX Pump Manual

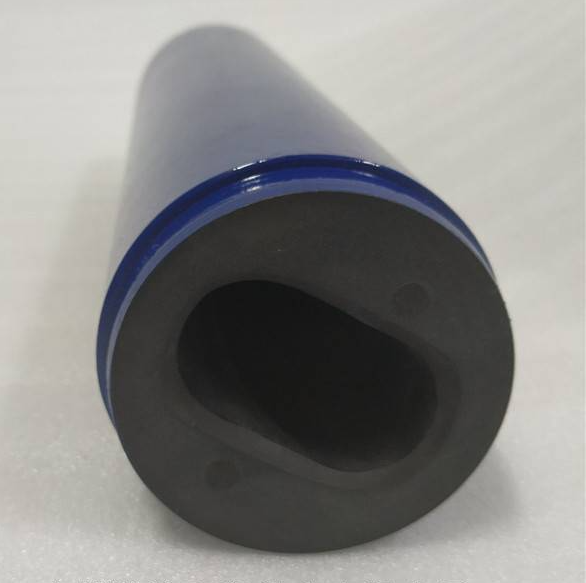

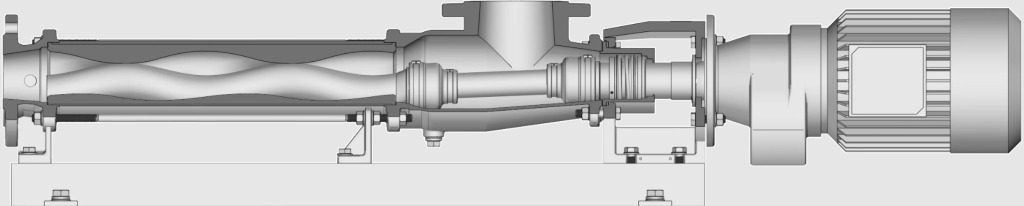

The SEEPEX pump is a type of progressive cavity pump that is designed for handling viscous and abrasive materials. It consists of a helical rotor that rotates inside a stator with a double helix internal profile. The interaction between the rotor and stator creates a series of sealed cavities that move the material from the inlet to the discharge port.

Application of SEEPEX Pump Manual

The SEEPEX pumps can handle a wide range of materials including liquids, semi-solids, and solids. It is commonly used in industries such as food and beverage, pharmaceutical, chemical, wastewater treatment, and oil and gas. Some common applications include transferring thick sludge, dosing additives, mixing and blending, and filling and packaging.

Features of SEEPEX Pump Manual

Gentle pumping action – The SEEPEX pump provides a consistent and gentle pumping action that minimizes shear and damage to the material being pumped.

High efficiency – The unique design of the SEEPEX pump ensures high volumetric efficiency and low energy consumption.

Easy maintenance – The simple construction of the SEEPEX pump allows for easy maintenance and replacement of parts without the need for special tools or training.

Flexible installation – The SEEPEX pump can be installed horizontally, vertically, or at any angle, making it suitable for a wide range of installations.

Hygienic design – The SEEPEX pump is available in a hygienic design with FDA-approved materials for use in food and beverage and pharmaceutical applications.

SEEPEX Pump Manual

The SEEPEX pump is a versatile and reliable pump that offers gentle pumping action, high efficiency, easy maintenance, flexible installation, and hygienic design. It is an ideal choice for handling viscous and abrasive materials in a variety of industrial applications.

Send Your Enquiry :