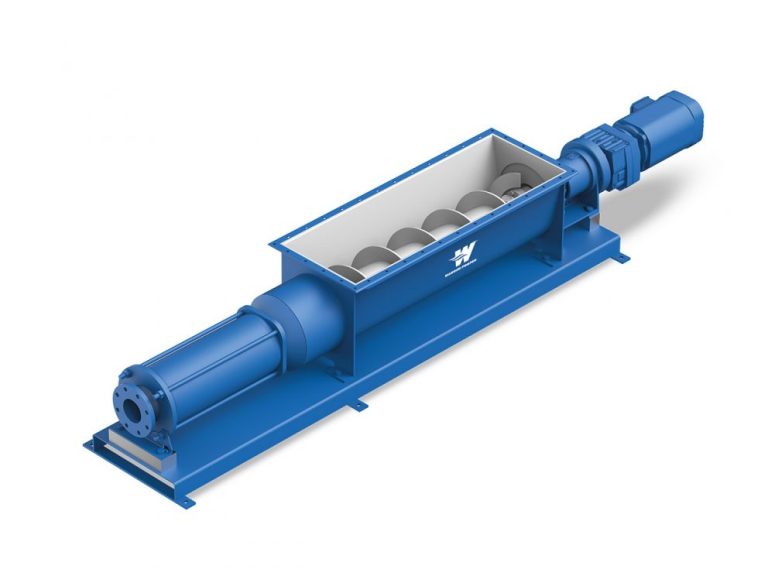

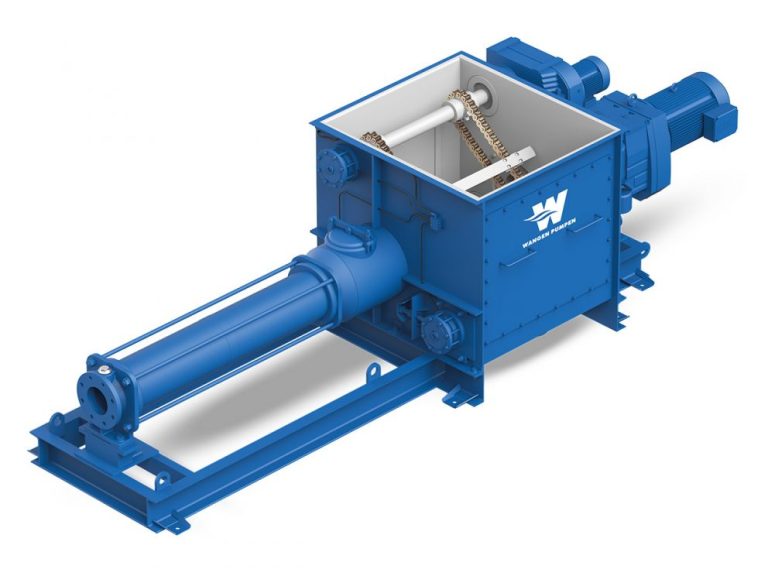

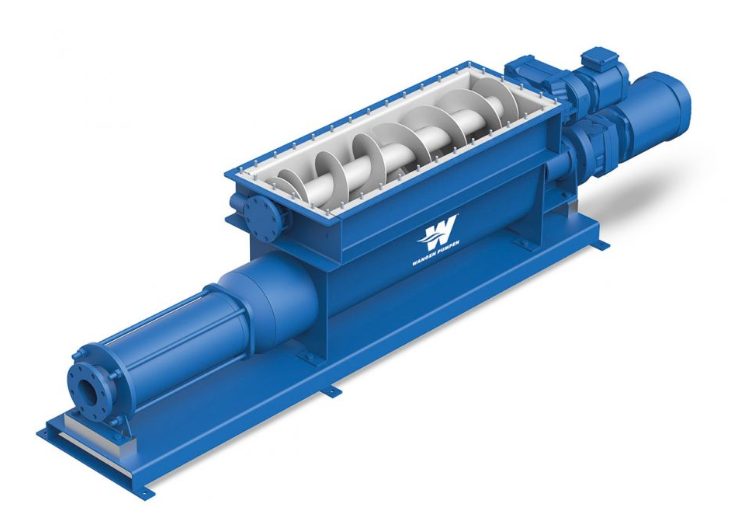

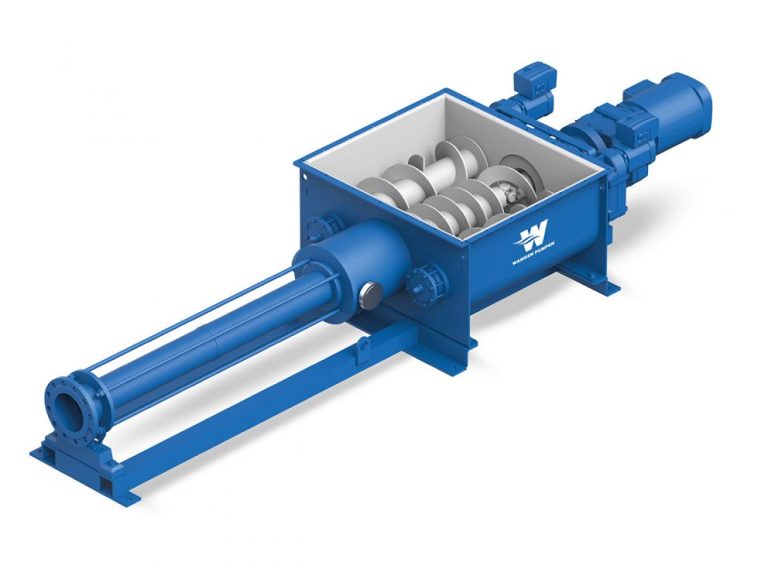

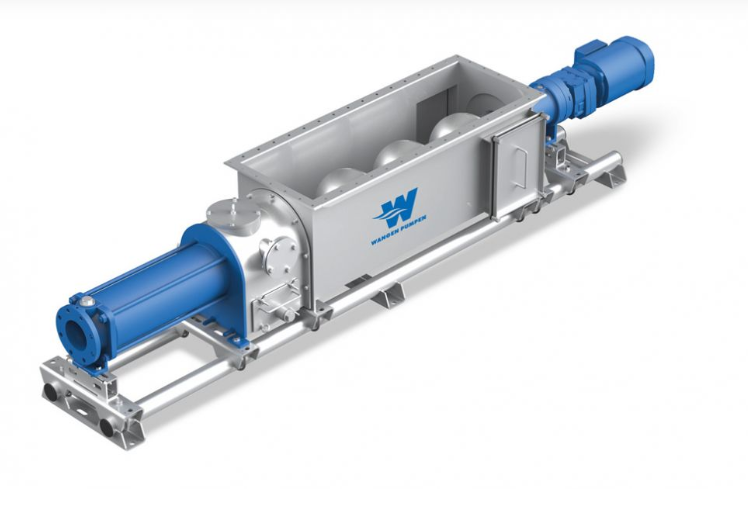

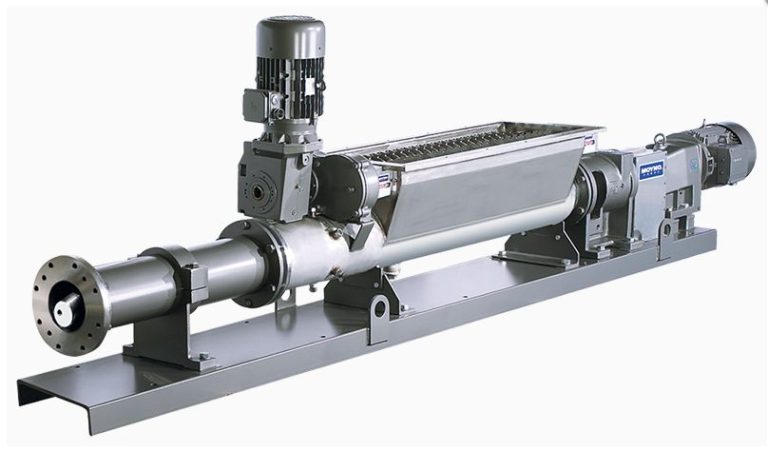

WANGEN Type KL-RF Hygienic Hygienic Hopper Feed Pump

Hygienic hopper feed pump Type KL-RF Hygienic The hygienic hopper feed pumps of the series WANGEN KL-RF have an inspection cover, a maintenance-free mechanical seal, which is independent of the rotation direction, and the dis-charge nozzle has a self-emptying design. The KL-RF is available with different rotor/stator geometric forms (S-, L- and H shapes). People Also Ask