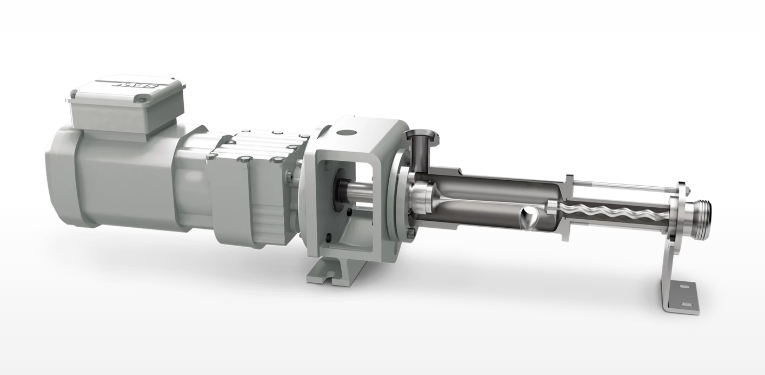

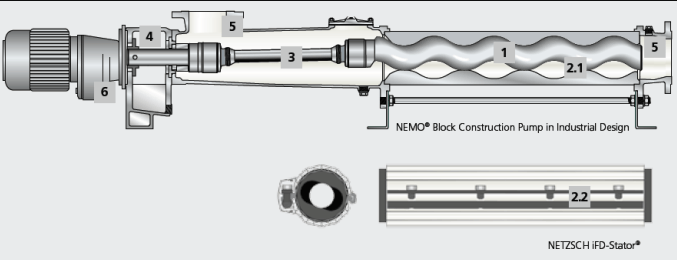

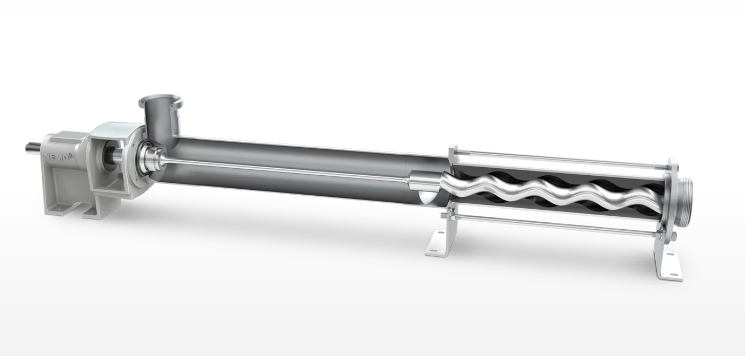

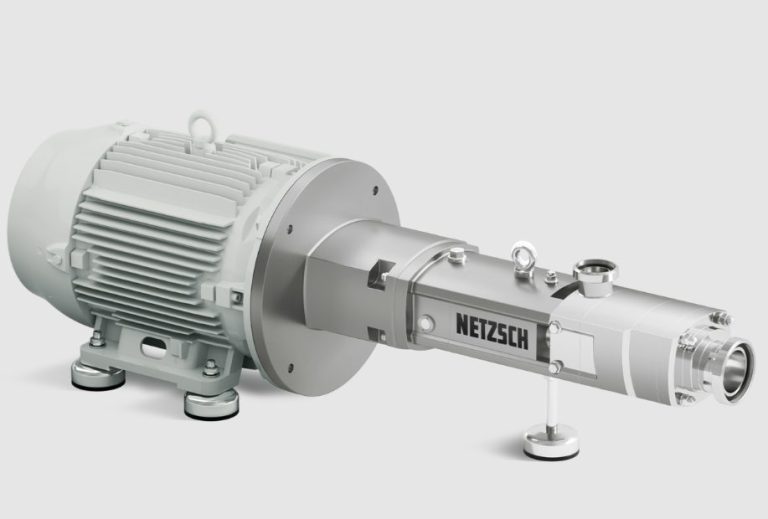

NETZSCH NEMO® BH Mini Hygienic Progressing Cavity Pump

NEMO® BH Mini Hygienic Pump The NEMO® BH Mini hygienic pump ensures continuous and low-pulsation conveying and is used for hygienic applications and optimum cleaning, especially in the food, pharmaceutical, cosmetics, chemical and biochemical industries. People Also Ask