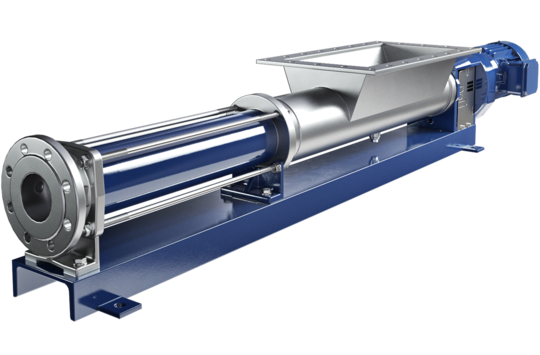

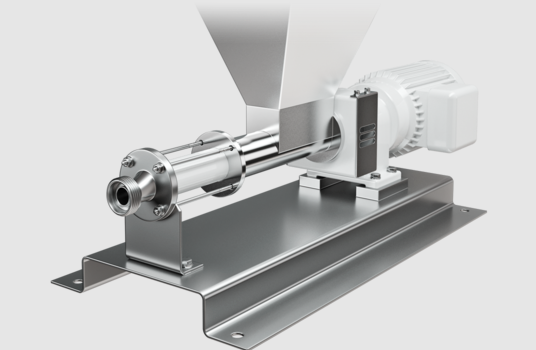

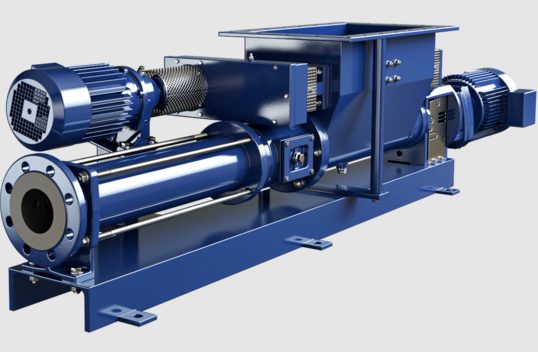

MOYNO G3 BRIDGE BREAKER Long-Coupled Pump

G3 – BRIDGE BREAKER High-performance 2000 Pumps offer low maintenance, minimal downtime and long service life for low total cost of ownership. People Also Ask

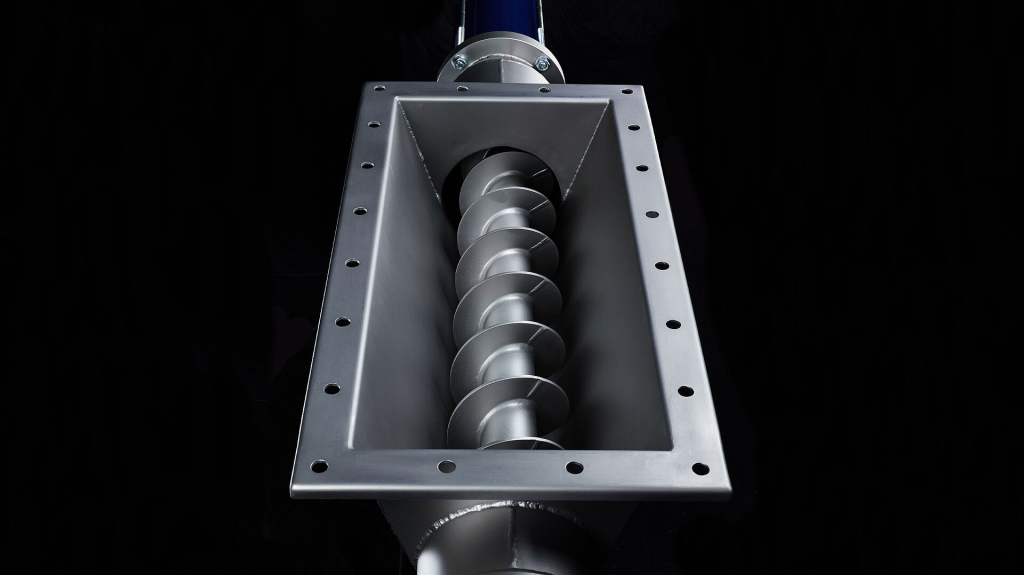

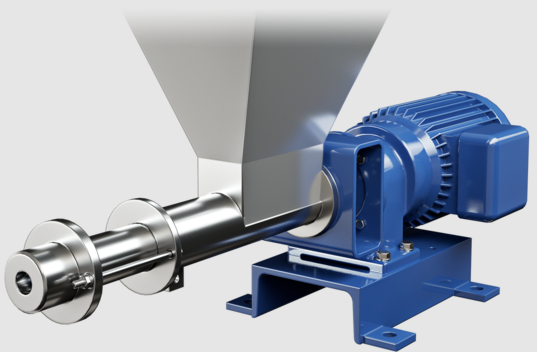

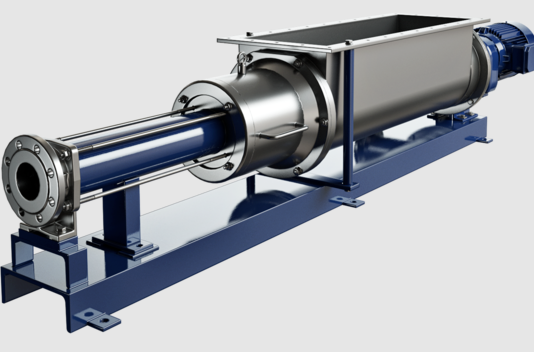

The hopper pump is an internal meshing rotary positive displacement pump. Its main working parts are the eccentric screw (rotor) and the fixed bushing (stator). Due to the special geometric shapes of the rotor and stator, several separate sealed cavities are formed. The operation of the rotor continuously and evenly transports the medium in each sealed cavity from the suction end to the discharge end. The internal flow rate is low, the volume remains unchanged, and the pressure is stable, so there will be no eddy current and agitation.

It can be used to transport neutral or corrosive liquids, clean or abrasive liquids, liquids containing gas or prone to bubble generation, high viscosity or low viscosity liquids, including liquids containing fibers and solid substances. It can work continuously for a long time and maintain a stable flow rate, and has good self-priming ability.

Because the stator is made of a variety of elastic materials, this pump is not suitable for conveying high-viscosity fluids and mediums containing hard suspended particles or fibers. Its flow rate is proportional to the speed. The transmission can be directly driven by a coupling, or by speed-adjusting motors, V-belts, gearboxes and other devices. This pump has few parts, compact structure, small size, and easy maintenance. The rotor and stator are the vulnerable parts of this pump, with a simple structure and easy assembly and disassembly.

Excellent medium conveying capacity

Requires continuous, stable pressure, and no periodic pressure fluctuations.

Convey high viscosity media.

Convey media containing solid particles or fibers.

Lower noise.

Non-pipeline connection, convenient and flexible feeding.

Requires small agitation and does not damage the inherent structure of the conveyed medium.

The length of the rectangular feed hopper can be adjusted according to the upstream components

Oil industry: heavy oil transportation, oil and gas mixing, oil-water separation and waste oil recovery system, sewage treatment, polymer transportation;

Chemical and pharmaceutical: various pastes, emulsions, suspensions, gas-containing and solid-containing liquids, and media that cannot be stirred and sheared;

Environmental engineering: various sewage transportation, dewatering, sludge transportation, metering and dosing of flocculants and their chemical preparations, oil-water separation and waste gas deterioration;

Mineral engineering: water-coal slurry equipment and production equipment for transportation of titanium dioxide, kaolin, calcium carbonate, etc., feeding cyclone fluids and filter bodies, chemical dosing and grouting, electrolyte treatment;

Food industry: dairy products, juice, puree, vegetable sauce, minced meat and condiments, beer and brewing;

Paper industry: raw material equipment, coating and coloring process, chemical dosing, pulping and wastewater treatment.

G3 – BRIDGE BREAKER High-performance 2000 Pumps offer low maintenance, minimal downtime and long service life for low total cost of ownership. People Also Ask

Open Hopper Cavity Pump Introduction Open Hopper Cavity Pump is a type of positive displacement pump that is designed to handle viscous and shear-sensitive materials. It has an open hopper or feeding area which allows for easy loading and unloading of the material being pumped. The pump’s unique design features a rotor that rotates inside…

The Description of Pump Hopper A pump hopper is an equipment used in the process of transferring materials from one location to another using a pump. It is designed to receive, store and feed material into the pump system efficiently and safely. The Application of Pump Hopper Pump hoppers are widely used in various industries…

DESIGNED TO IMPROVE INTAKE EFFICIENCY ON HIGHLY VISCOUS MEDIA SEEPEX MDT range pumps are used to convey highly viscous media such as peanut butter, molasses, resins, and other media with low flowability. The open hopper on the pump directs media to the auger feed screw on the coupling rod which feeds the media into the…

DESIGNED TO IMPROVE INTAKE EFFICIENCY ON HIGHLY VISCOUS MEDIA The MDTC range is the hygienic food grade version of the open hopper metering pump. It is used in a variety of applications in the food, beverage, pharmaceutical, and cosmetic industries to convey low to highly viscous media with low flowability. The pumps meet the highest…

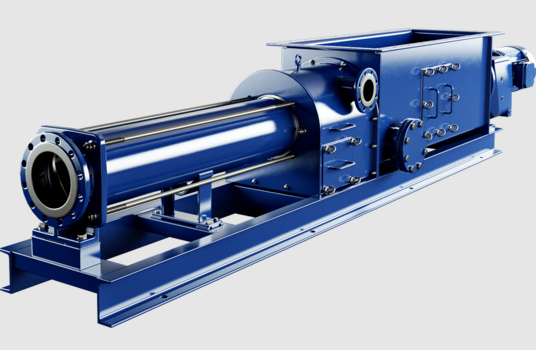

MADE FOR EXTREMES Powerful under extreme conditions: the BTEX hopper pumps SEEPEX are robustly built and designed with reinforced individual components for tough applications – e.g. for fermentation products in the agriculture and biogas industries. They are designed to allow contaminants to settle at the base of the hopper and be removed quickly and easily…

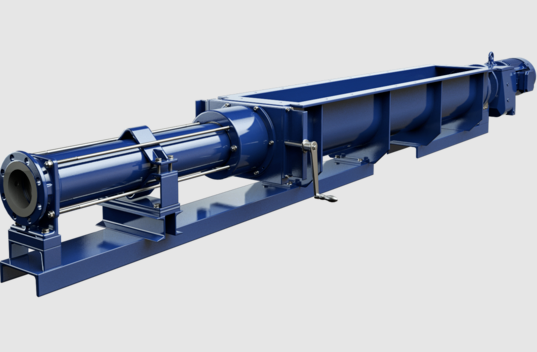

BTES – HOPPER PUMP FOR SILO SYSTEMS Made for silos: With their long hoppers, BTES hopper pumps from SEEPEX are ideal for installation under a silo. The construction of the rectangular hopper can then be optimally adapted to a wide variety of silo discharge systems. The pumps are ideal for pumping e.g. dewatered sewage sludge…

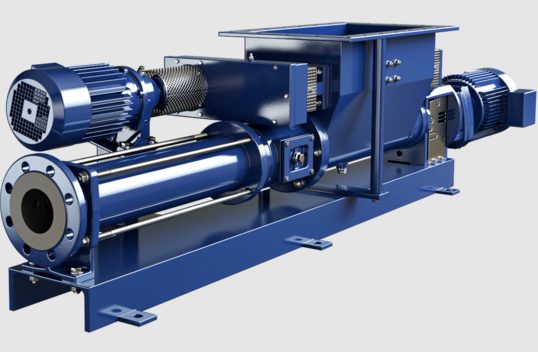

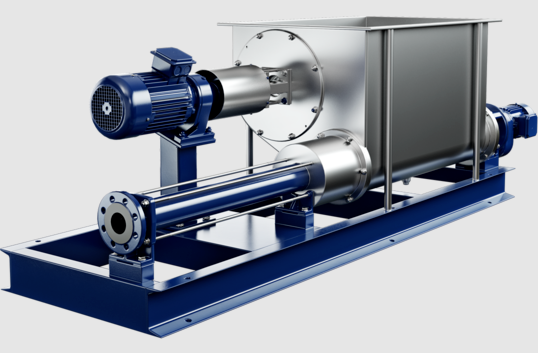

PERPETUAL MOTION No stoppages, no bridging: to ensure the feed medium can be optimally pumped at all times, there is a bridge breaker above the screw conveyor in the rectangular hopper of the BTEI hopper pump from SEEPEX. The separately driven rotating paddle keeps the medium in constant motion, thus avoiding the formation of bridges….

REALLY WELL MIXED When media are inclined to bridging, smooth product delivery to the conveying elements cannot always be assured. The BTI hopper pumps from SEEPEX provides a solution. The rectangular hopper contains two counter-running paddle shafts equipped with their own drive system. These mix highly viscous media so thoroughly that bridging cannot even begin…

FROM HIGHLY VISCOUS TO SEMI-SOLID BTVE hopper pumps from SEEPEX provide the ability to transport dewatered sludge with a dry matter content of up to 30%. A large, rectangular intake hopper with screw conveyor allows them to easily be fed with highly viscous and semi-solid products with no tendency towards bridging. A roller-mounted sliding compression…