Direct-Coupled Progressing Cavity Pumps in Industrial Design

What is a direct-coupled progressing cavity pump in industrial design ? Direct-connected progressive cavity pump has no bearing seat, and the prime Mover …

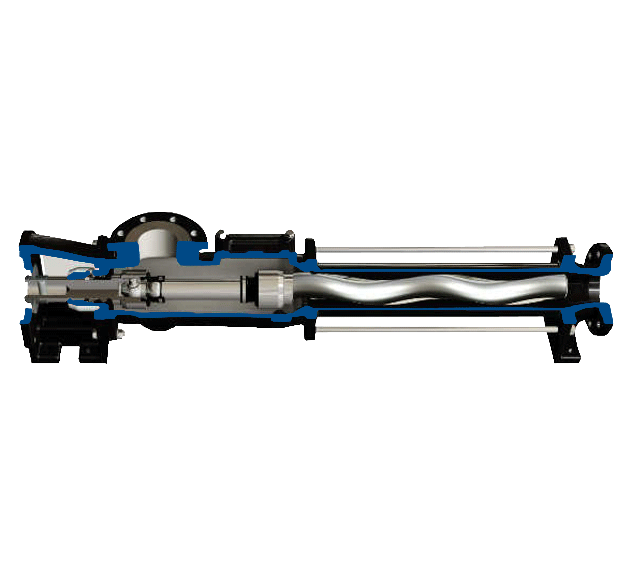

The industrial progressive cavity pump is a key equipment widely used in various industrial fields. This unique pump structure consists of a spiral rotor and a fixed stator, which can achieve efficient, smooth and low-pulsation fluid delivery.

The biggest advantage of the progressive cavity pump is its excellent self-priming ability, which can handle media containing solid particles or fibers. This makes it an ideal choice for chemical, food processing, environmental protection and other fields. At the same time, this pump type has the characteristics of wear resistance and corrosion resistance, and can be widely used in the delivery of viscous fluids such as lubricating oil, grease, syrup, etc.

In addition, the industrial progressive cavity pump is very compact in structure, easy to install and maintain, and runs smoothly, with low noise and high reliability. With the continuous advancement of technology, the performance of this pump type has been continuously optimized, occupying an important position in many industries, meeting the needs of modern industry for high efficiency, energy saving and environmental protection.

What is a direct-coupled progressing cavity pump in industrial design ? Direct-connected progressive cavity pump has no bearing seat, and the prime Mover …

Food grade progressive cavity pump is also a kind of progressive cavity pump, its biggest feature is that the material can meet the requirements of food industry. The common material of current passing parts is stainless steel 304 and 316L, and the stator …

PMV Pump has launched a new progressive cavity pump designed specifically to enable the precise dosing of fluids and pastes proportionate to …