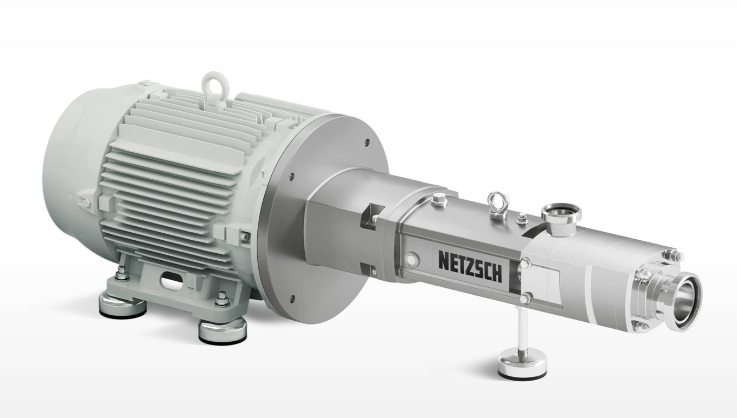

Direct-Coupled Progressing Cavity Pumps in Industrial Design

Q=0.5-300 m³/h (2.2 USGPM – 1321 USGPM)

P=0~2.4 Mpa (0~348 psi)

What is adirect-coupled progressing cavity pump in industrial design ?

Direct-connected progressive cavity pump has no bearing seat, and the prime Mover bears the axial force of the progressive cavity pump, connecting the driving end and the flange at the end of the pump into a whole.

Direct coupled pump structure is compact and its axial dimension is short. Low investment, use and maintenance costs.

It is mainly used in environmental protection technology, food and chemical industries, etc., and can also meet various pressures of the petroleum industry, with stable delivery or precise administration.

[video_lightbox_youtube video_id=”JWkoODah0vY&rel=0″ width=”640″ height=”480″ alt=”Sludge Screw Pump” anchor=”https://pumpvv.com/wp-content/uploads/2023/03/pump-cover1.png”]

The direct-Coupled Progressing Cavity Pumps features

- Gentle transportation

- Suitable for all kinds of media with high viscosity and containing solid particles

- Convenient disassembly and maintenance

- Rotor / stator with various geometry and materials

- Compact structure and small occupied area

- The right joint for any application

- Small mechanical vibration, no vibration and stable operation

- Standard mechanical seal, other seals optional

- Speed is proportional to rotational speed

PMV Direct-Coupled Progressing Cavity Pumps Parameter Table

| Pump Type | Pressure Range (bar) | Capacity Range (m³/h) | Speed Range (rpm) | Inlet Size (G/DN) | Outlet Size (G/DN) | Motor Power (KW) |

|---|---|---|---|---|---|---|

| MJN025-2S | 0~12 | 0~0.25 | 0~350 | G1¼ | G1¼ | 0.37 |

| MJN05-1L | 0~6 | 0~0.5 | 0~350 | G1¼ | G1¼ | 0.37 |

| MJN05-2S | 0~12 | 0~0.5 | 0~350 | G1¼ | G1¼ | 0.75 |

| MJN1-1L | 0~6 | 0~1 | 0~350 | G1¼ | G1¼ | 0.75 |

| MJN1-2S | 0~12 | 0~1 | 0~350 | 50 | 50 | 1.5 |

| MJN1-4S | 0~24 | 0~0.5 | 0~250 | 50 | 50 | 3 |

| MJN3-1L | 0~6 | 0~3 | 0~350 | 50 | 50 | 2.2 |

| MJN3-2S | 0~12 | 0~2.5 | 0~350 | 65 | 65 | 3 |

| MJN3-4S | 0~24 | 0~1.5 | 0~250 | 65 | 65 | 5.5 |

| MJN5-1L | 0~6 | 0~5 | 0~320 | 65 | 65 | 3 |

| MJN5-2S | 0~12 | 0~5 | 0~320 | 80 | 80 | 4 |

| MJN5-3S | 0~18 | 0~3 | 0~250 | 80 | 80 | 5.5 |

| MJN5-4S | 0~24 | 0~2 | 0~200 | 80 | 80 | 7.5 |

| MJN10-1L | 0~6 | 0~10 | 0~300 | 80 | 80 | 4 |

| MJN10-2S | 0~12 | 0~7 | 0~300 | 80 | 80 | 5.5 |

| MJN10-3S | 0~18 | 0~6 | 0~250 | 80 | 80 | 7.5 |

| MJN10-4S | 0~24 | 0~4 | 0~200 | 80 | 80 | 11 |

| MJN15-1L | 0~6 | 0~15 | 0~300 | 80 | 80 | 5.5 |

| MJN15-2S | 0~12 | 0~12 | 0~300 | 100 | 100 | 7.5 |

| MJN15-3S | 0~18 | 0~10 | 0~250 | 100 | 100 | 11 |

| MJN15-4S | 0~24 | 0~7 | 0~200 | 100 | 100 | 15 |

| MJN25-1L | 0~6 | 0~25 | 0~280 | 100 | 100 | 7.5 |

| MJN25-2S | 0~12 | 0~22 | 0~300 | 125 | 125 | 11 |

| MJN25-3S | 0~18 | 0~15 | 0~250 | 125 | 125 | 15 |

| MJN25-4S | 0~24 | 0~12 | 0~200 | 125 | 125 | 18.5 |

| MJN50-1L | 0~6 | 0~50 | 0~280 | 125 | 125 | 11 |

| MJN50-2S | 0~12 | 0~35 | 0~250 | 150 | 150 | 22 |

| MJN50-3S | 0~18 | 0~30 | 0~230 | 150 | 150 | 30 |

| MJN50-4S | 0~24 | 0~26 | 0~200 | 150 | 150 | 37 |

| MJN80-1L | 0~6 | 0~80 | 0~280 | 150 | 150 | 22 |

| MJN80-2S | 0~12 | 0~60 | 0~280 | 150 | 150 | 37 |

| MJN80-3S | 0~18 | 0~42 | 0~200 | 150 | 150 | 45 |

| MJN80-4S | 0~24 | 0~25 | 0~150 | 150 | 150 | 55 |

| MJN120-1L | 0~6 | 0~120 | 0~250 | 150 | 150 | 37 |

| MJN120-2S | 0~12 | 0~100 | 0~270 | 200 | 200 | 45 |

| MJN120-3S | 0~18 | 0~60 | 0~180 | 200 | 200 | 55 |

| MJN120-4S | 0~24 | 0~50 | 0~150 | 200 | 200 | 55 |

| MJN180-1L | 0~6 | 0~180 | 0~220 | 200 | 200 | 45 |

| MJN180-2S | 0~12 | 0~170 | 0~220 | 200 | 200 | 55 |

| MJN300-1L | 0~6 | 0~300 | 0~220 | 200 | 200 | 55 |

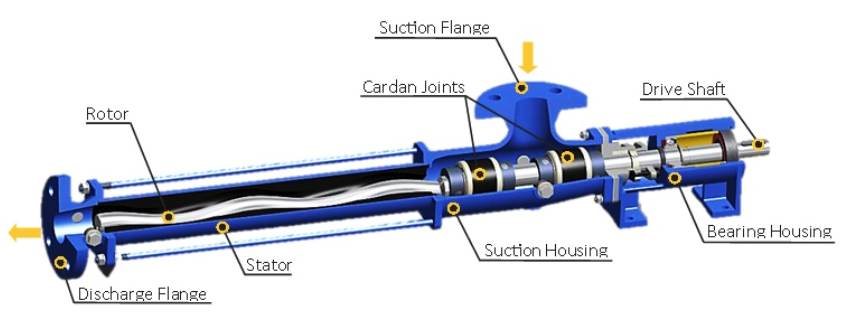

PMV progressive cavity pump parts

PMV progressive cavity pump for sale/progressive cavity pump design

The Applications of Direct-Coupled Progressing Cavity Pumps

Direct-connected progressing cavity pump can be used to transport neutral or corrosive liquids, clean and abrasive liquids, liquids containing gas or easily generating bubbles, and liquids with high viscosity or low viscosity (including liquids containing fibers or solid substances)

Environmental protection: the transportation of industrial sewage, domestic sewage and sludge turbid water containing solid particles and short fibers, especially suitable for oil-water separators, plate filter presses and other equipment

Shipbuilding industry: used for transporting residual oil, cleaning tanks, sewage, seawater, etc.;

Petrochemical industry: used for transportation of various oils, especially crude oil;

Textile industry: used for conveying synthetic fiber liquid, viscose liquid, dye, nylon powder, etc.

Medicine and daily chemicals: transportation of various viscous pastes, emulsions and various ointment cosmetics, etc.

Canned food industry: transportation of all kinds of sticky starch, edible oil, honey, sugar sauce, fruit pulp, cream, fish and leftovers;

Brewing industry: all kinds of fermented viscous liquids, concentrated distiller’s grains, grain product residues, all kinds of sauces, pulps and mucus containing massive solid substances, etc.;

Construction industry: spraying and conveying of cement slurry, lime slurry, paint and other pastes;

Metallurgy and mining industry: used to transport oxides and wastewater, mine drainage and liquid explosives, etc.;

Chemical industry: transportation of various suspensions, grease, colloidal slurries, adhesives, paper making, printing, high viscosity ink, black liquor of paper pulp, PVC polymer plastic paste of paper, pulp with various concentrations, short fiber slurry, etc.progressive cavity pump design

People Also Ask

Send Your Enquiry :