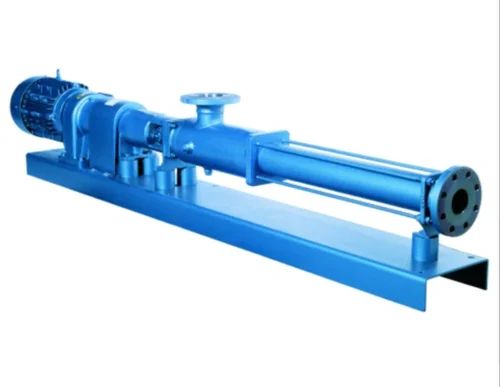

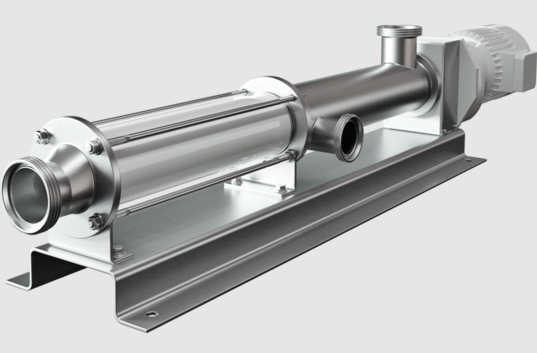

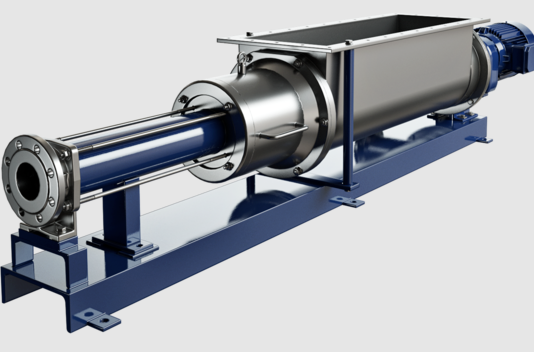

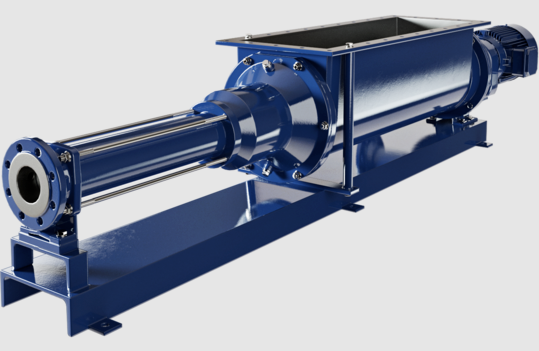

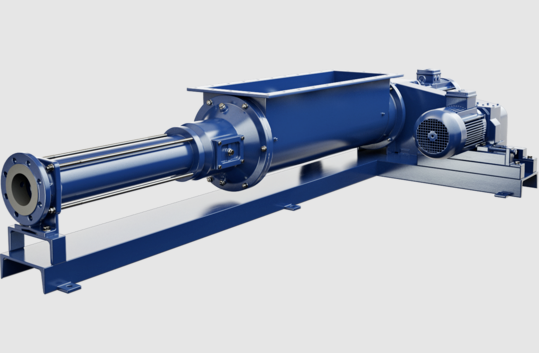

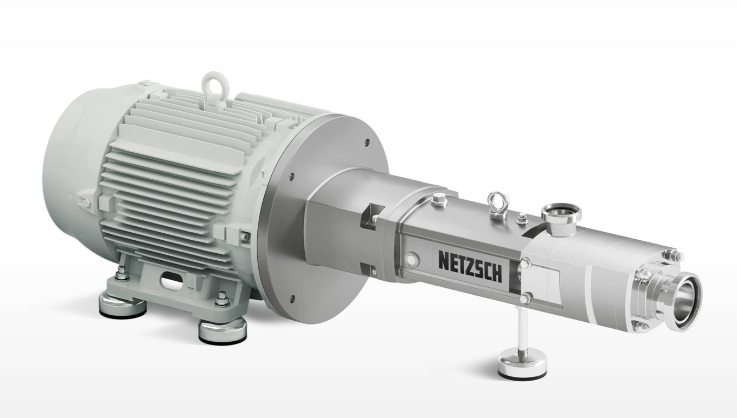

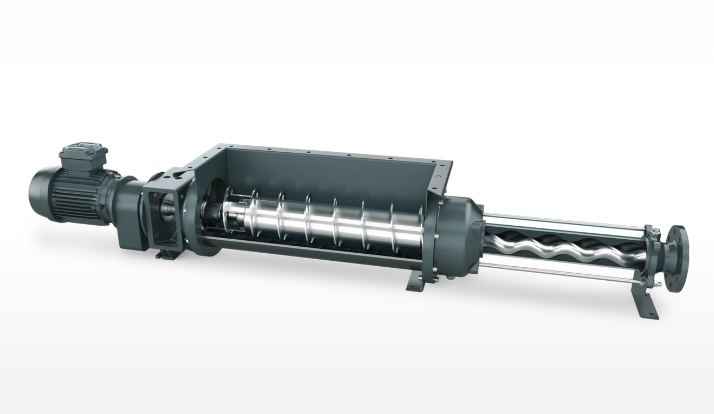

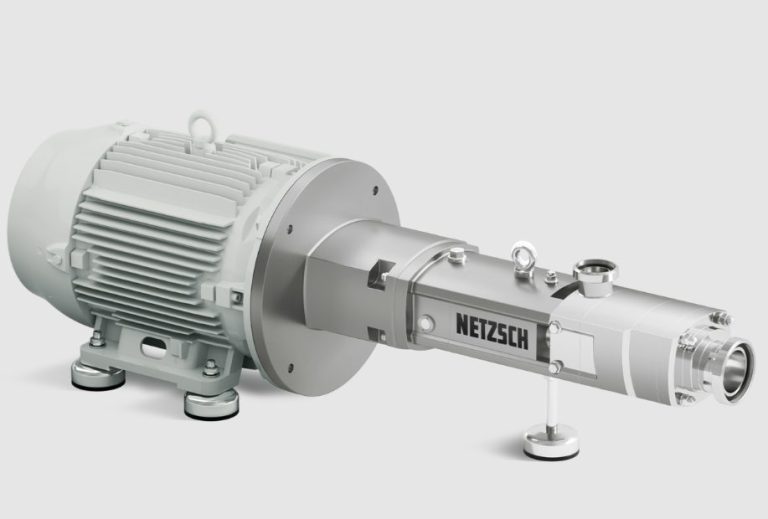

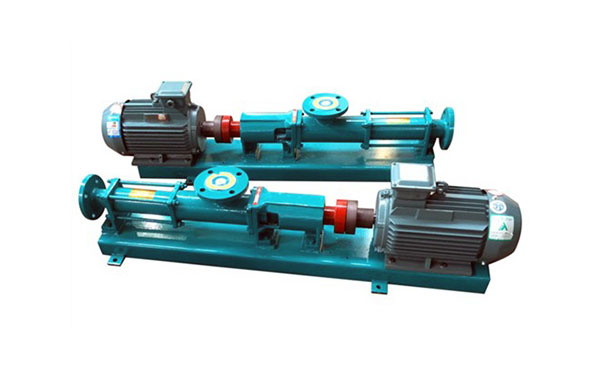

Hygienic Twin Screw Pump

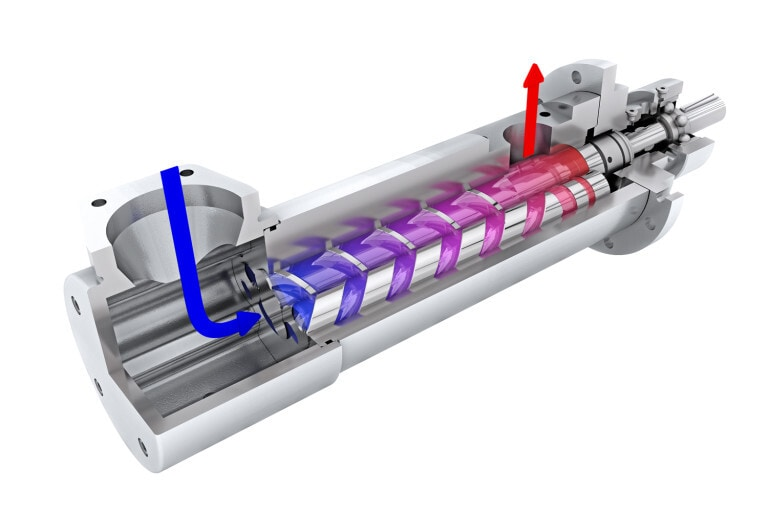

Hygienic Twin Screw Pump, More Commonly Known as Sanitary Twin Screw Pump. The hygienic twin screw pump is an advanced pumping solution designed for applications requiring high hygiene standards. It is generally know as a sanitary twin screw pump,and specifically developed to handle sensitive and viscous fluids in industries such as food and beverage, pharmaceuticals,…