BN26-12 seepex BN

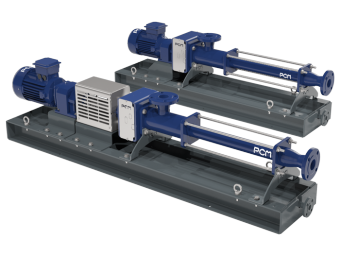

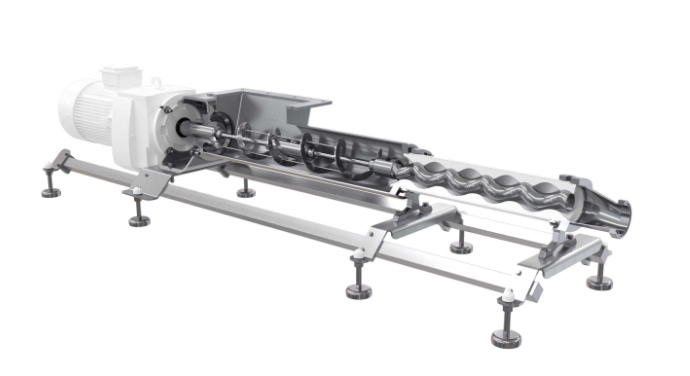

Parameters Innovative design of seepex BN26-12 seepex BN26-12 is a high-performance screw pump component designed to meet the needs of various demanding industrial applications. The component is made of high-quality wear-resistant and corrosion-resistant materials to ensure excellent performance when handling various corrosive or abrasive fluids. The core components of BN26-12 are rotor and stator. The…