Direct-Coupled Progressing Cavity Pumps in Industrial Design

What is a direct-coupled progressing cavity pump in industrial design ? Direct-connected progressive cavity pump has no bearing seat, and the prime Mover …

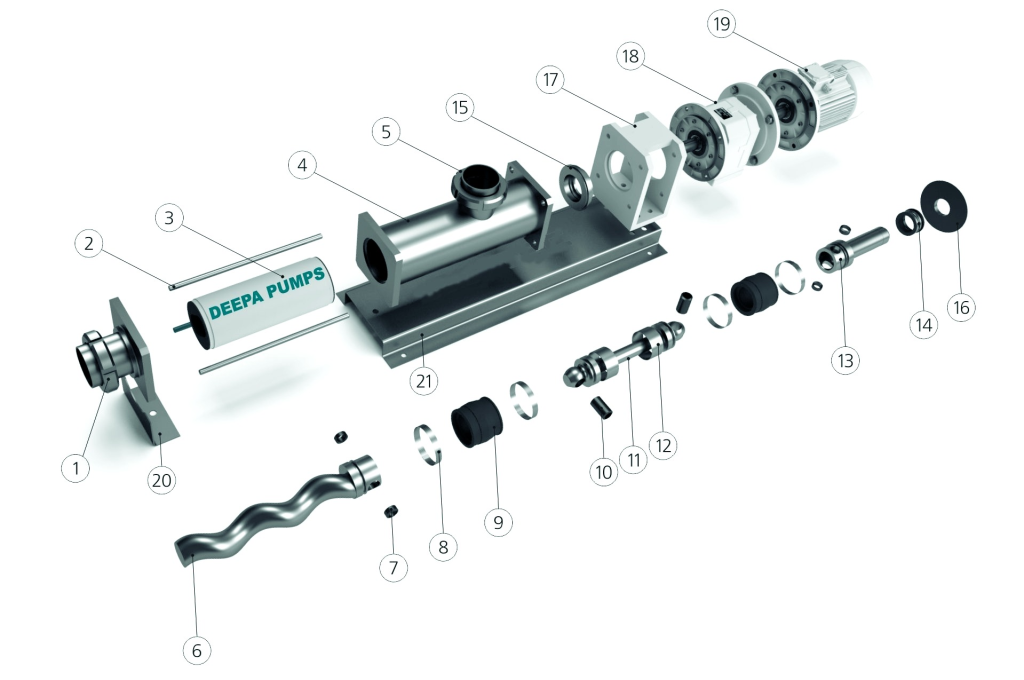

In industrial environments, various pump equipment plays a vital role. Among them, progressive cavity pumps are becoming increasingly popular due to their unique design and excellent performance. The main components of progressive cavity pumps include rotors, stators, and pump casings. The rotor is spiral-shaped, which matches the spiral shape of the stator’s inner cavity to form a unique working chamber. During the operation of the pump, these working chambers move along the rotor axis, resulting in a continuous delivery effect.

Progressive cavity pumps have many advantages, such as stable flow, wear resistance, and strong self-priming ability. This makes them widely used in many industries such as petrochemicals, food and beverages, and mining. In terms of maintenance, regular inspection and replacement of key components of progressive cavity pumps, such as rotors and stators, are essential to ensure the long-term stable operation of the equipment. Through optimized design and careful maintenance, progressive cavity pumps can provide reliable and efficient liquid delivery solutions for various industrial applications.

What is a direct-coupled progressing cavity pump in industrial design ? Direct-connected progressive cavity pump has no bearing seat, and the prime Mover …

PMV Pump has launched a new progressive cavity pump designed specifically to enable the precise dosing of fluids and pastes proportionate to …