PCM HYFEED HYGIENIC HOPPER PROGRESSING CAVITY PUMPS

Hygienic PCM HyFeed progressive cavity pump The PCM force feeding pumps are adapted to your needs for the transfer of viscous and heterogeneous products. People Also Ask

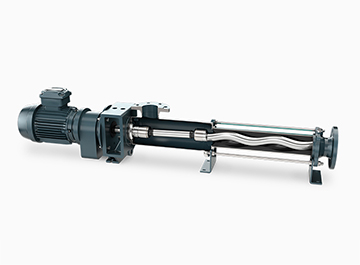

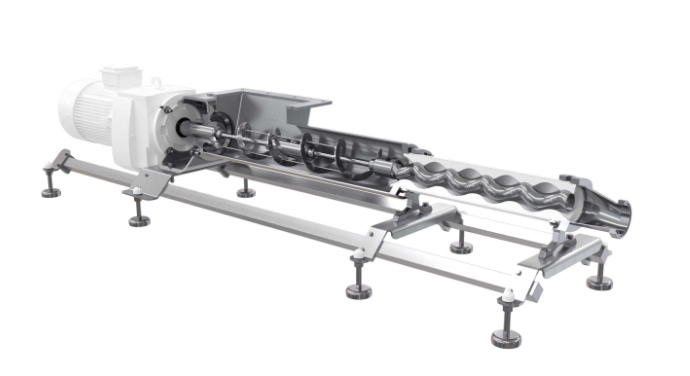

The main working parts of a single screw pump are composed of a sleeve (stator) with a double-headed spiral cavity and a single-headed eccentric screw (rotor) meshed with it in the stator cavity. Since the medium of a single screw pump is pushed axially and evenly to flow, the internal flow velocity is low, the pressure is stable, and no eddy current or agitation is generated; it is suitable for conveying high viscosity, containing solid particles or high fiber, and requiring continuous and stable pressure.

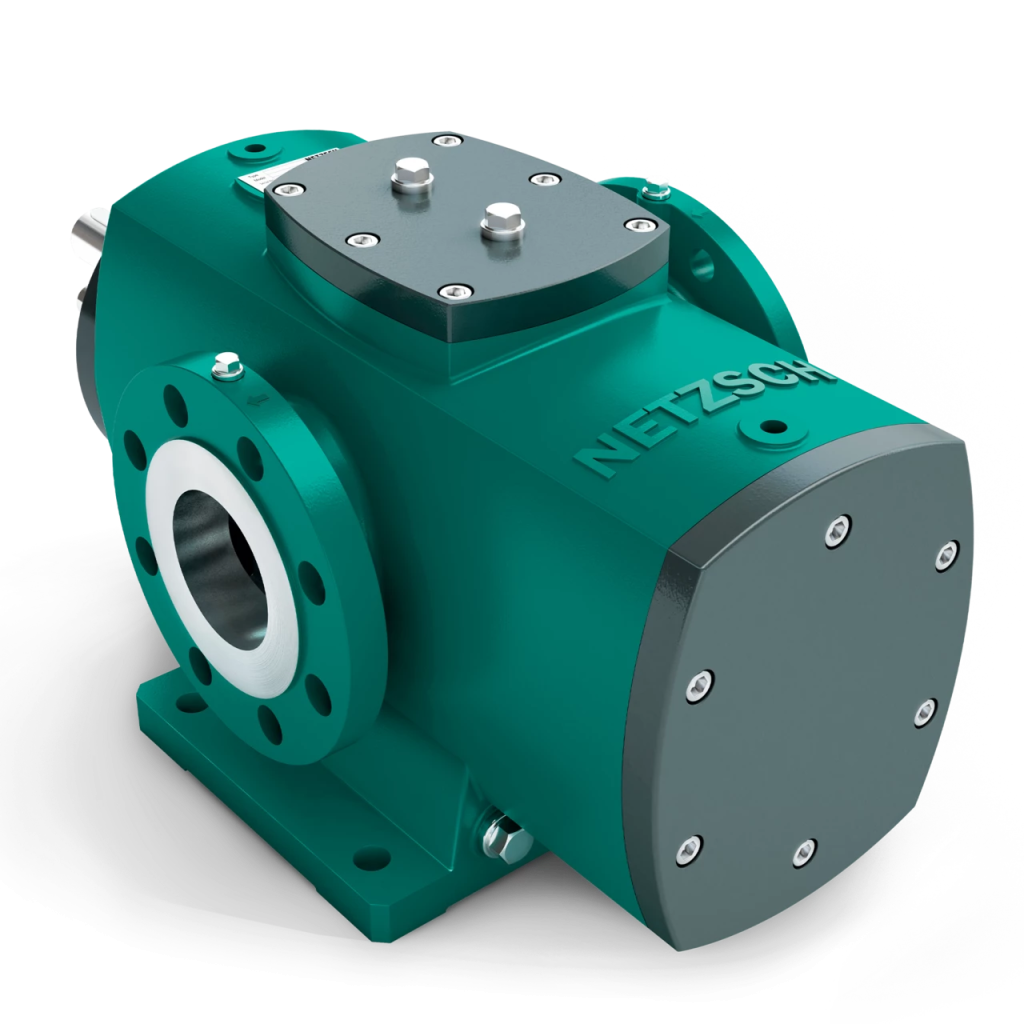

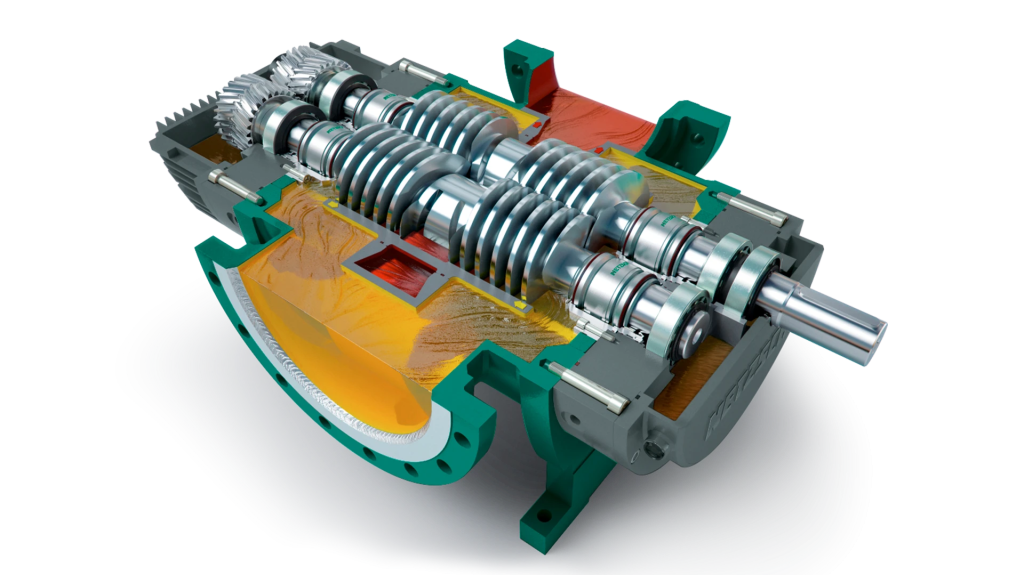

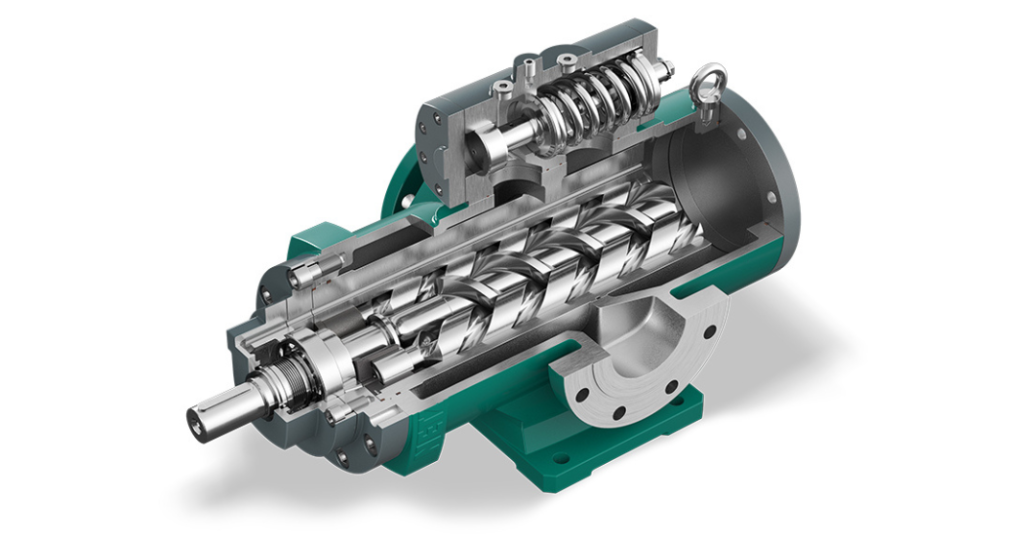

One of the twin-screw, three-screw, and five-screw pumps is an active screw, which is a right-handed convex screw, and the rest are driven screws, which are left-handed concave screws. When the screw rotates, the volume of the suction chamber increases and the pressure decreases. The liquid enters the suction chamber along the suction pipe under the action of the pressure difference between the inside and outside of the pump. As the screw rotates, the liquid in the sealed chamber moves continuously and evenly along the axial direction to the discharge chamber. As the volume of one end of the discharge chamber gradually decreases, the liquid is discharged.

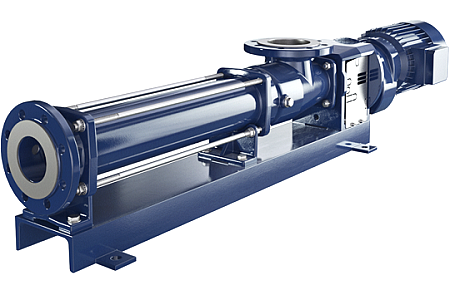

A twin-screw pump is an externally meshed screw pump, which uses two screws that mesh with each other and do not contact each other to pump liquid. The unique structure enables it to realize non-stirring, non-pulsating and stable conveying of various media; because the pump body structure ensures that the pumping liquid is always present in the working element of the pump as a sealing liquid, the twin-screw pump has a strong self-priming ability, and its special design also ensures that the pump has a high suction performance, that is, a very small NPSHr value.

The three-screw pump is mainly composed of a bushing fixed in the pump body, an active screw inserted in the pump cylinder, and two driven screws meshing with it. Since the two driven screws mesh symmetrically with the active screw, the radial force acting on the active screw of the three-screw pump is completely balanced, and the active screw does not bear bending load. The radial force on the driven screw is supported by the pump cylinder bushing along its entire length, and no bearing is required at the outer end, and it basically does not bear bending load. The remarkable features of the three-screw pump are simple structure, small pressure pulsation, stable flow, stable and reliable operation, high speed, low noise, high efficiency, long life, and self-priming ability.

Wide pressure and flow range;

Wide range of types and viscosities of transported liquids;

High speeds can be used because the rotating parts in the pump have low inertia;

Good suction performance and self-priming ability;

Uniform and continuous flow, low vibration and low noise;

Less sensitive to incoming gas and dirt than other rotary pumps;

Solid structure and easy installation and maintenance.

Hygienic PCM HyFeed progressive cavity pump The PCM force feeding pumps are adapted to your needs for the transfer of viscous and heterogeneous products. People Also Ask

PCM EASYFEED HOPPER PROGRESSING CAVITY PUMPS The growing demand for more concentrated and sophisticated products often implies an increase in the viscosity of the products being transferred. If your product is viscous, pasty, sticky, greasy, thick, or concentrated, PCM provides an appropriate solution for each type of rheology through its range of force feeding progressing…

ECOMOINEAU™ C SMALL INDUSTRIAL PROGRESSING CAVITY PUMPS The EcoMoineau™ C pump is the shortest stainless steel progressing cavity pump available in the market. People Also Ask

HYCARE™ SANITARY PROGRESSING CAVITY PUMP PCM HyCare™ is the world’s gentlest, most hygienic food sanitary pump. It’s been especially designed for food applications, featuring a patented body design developed using advanced computational fluid dynamics. This progressing cavity pump will treat your ingredients, food safety requirements and budget with the care and respect they deserve. People Also Ask

Slurry Pump EZstrip™ W Series The EZstrip™ W Series Pump features a specially designed feed chamber that can easily be disconnected allowing access to the rotating assembly. The rotor can be separated from the conveyor allowing removal of the rotor and stator all within its own assembled length. This process can take as little as 6…

EZstrip™ Z series Slurry Pump The Moyon EZstrip™ Z series slurry pump is a highly efficient and easy-to-maintain pump designed for handling abrasive slurries in industries such as mining, wastewater treatment, and chemical processing. Its unique design allows for quick and effortless disassembly and reassembly of the pump, significantly reducing downtime for maintenance and repair….

Dosing/Metering Progressing Cavity Pumps Moyno new line of pumps offering an efficient, reliable and low maintenance solution for applications where low flow, accurate dosing/metering is required. The Moyno dosing/metering pumps provide a smooth pumping action with no pulsation and very low shear. Ideal for either intermittent or continuous duties. People Also Ask

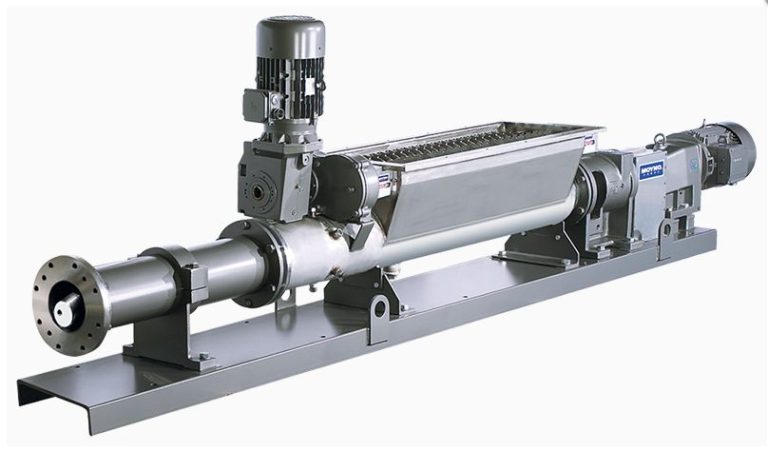

Chopper Hopper Pump Moyno has created a food products processor that combines solids reduction and transfer pumping into one efficient unit. The patented Chopper Hopper™ is a unique and aggressive solids reduction pumping system that reduces whole produce – papayas, pineapples, pumpkins or any other fruits or vegetables – into an easy to handle puree…

Moyno AugMentor Pump The AugMentor® Pump Stuffer handles high-viscosity materials otherwise unpumpable by conventional means. Materials in excess of 1,000,000 cps, such as cold processed meats and bakery dough, are easily fed by the AugMentor’s slow-speed, bottom-drive auger. People Also Ask

Moyno Sanitary High Pressure Pumps Moyno sanitary high pressure pumps are modified versions of the series 2000 progressive cavity pumps. Suitable for hygienic applications wher high flow rates at high pressure are required to pump high viscosity products. Pumps meet 3A and BISSC standards and also feature CIP capabilities. People Also Ask