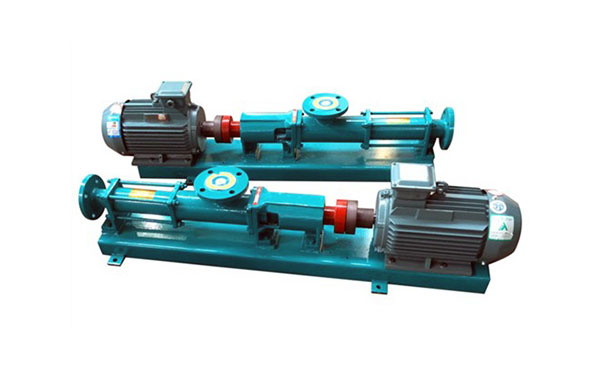

Pump Screw-PMV Pump

People Also Ask

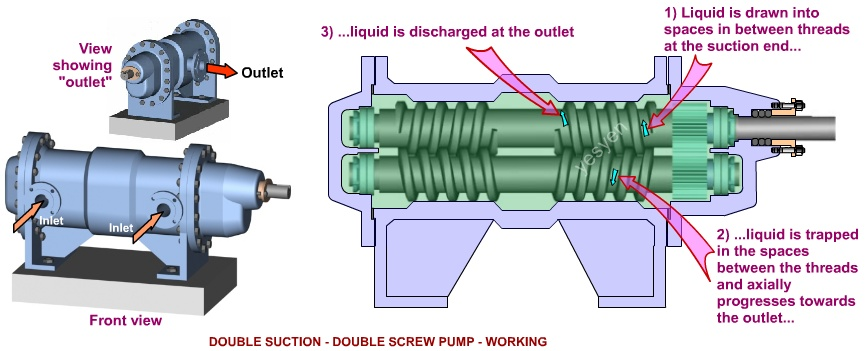

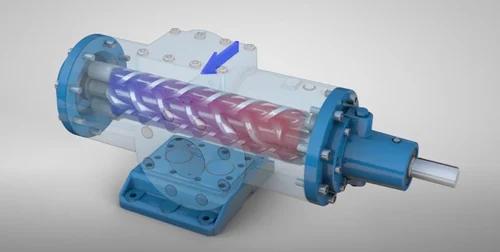

A rotary screw pump is a type of positive displacement pump that uses two interlocking screws to move fluids efficiently. This design allows for a continuous flow of liquid, making it suitable for various applications across multiple industries, including oil and gas, chemical processing, and water treatment.

Rotary screw pumps are utilized in a variety of industries and applications, including:

People Also Ask

What is a screw pump? Screw pump is a part of the dry compressed gas transfer pump series. They are positive displacement pumps that use one or more screws to move fluid or water along the screw shaft. These screws interlock to pressurize the fluid and move it into the system. These screws engage each…

The Description of Screw Pump A screw pump is a type of positive displacement pump that utilizes an intermeshing screw and housing to transfer fluids or viscous substances. The pump consists of two or more screws (also known as rotors) that rotate in opposite directions, creating chambers that trap and move the fluid along the…

Introduction to Screw Pump Diagram. A screw pump diagram is a schematic representation of the working principle and components of a screw pump. Screw pumps are positive displacement pumps that use rotating screws to move fluids or slurries through a system. They are widely used in various industries due to their ability to handle high…

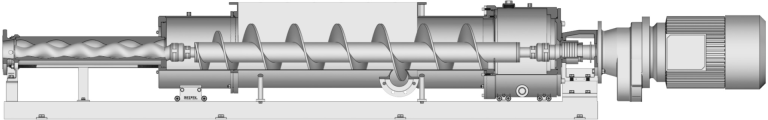

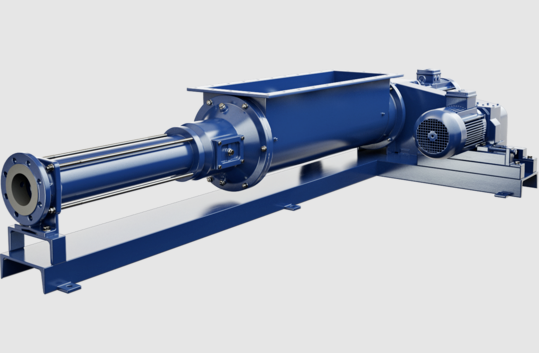

SIMULTANEOUSLY FAST AND SLOW Always the right speed: Because the ribbon screw of the BTH hopper pump from SEEPEX has its own separate second drive system, it can be operated at a different speed from the rotating unit. Thanks to the large diameter and elongated pitch of the edge-to-edge ribbon screw, even media that tend…

Sludge Screw Pump What is Sludge Screw Pump? Sludge screw pump that use one or several screws to move fluids or solids along the screw(s) axis. In its simplest form (the Archimedes’ screw pump), a single screw rotates in a cylindrical cavity, thereby moving the material along the screw’s spindle. The specific application of the…

Single Screw pump What is single screw pump? Single screw pump is a type of rotary positive displacement pump that operate according to the positive displacement principle. Single screw pump working principle is based on the interaction between a single-helix metal rotor and a double-helix elastic stator, which creates sealed cavities that move fluid from…