Pump Screw-PMV Pump

People Also Ask

A sanitary screw pump is a specialized type of pump designed for the hygienic transfer of various fluids, particularly in industries such as food, beverage, pharmaceutical, and biotechnology. These pumps are engineered to meet stringent sanitation standards, ensuring the safe handling of sensitive materials.

Sanitary screw pumps are commonly used in various applications, including:

People Also Ask

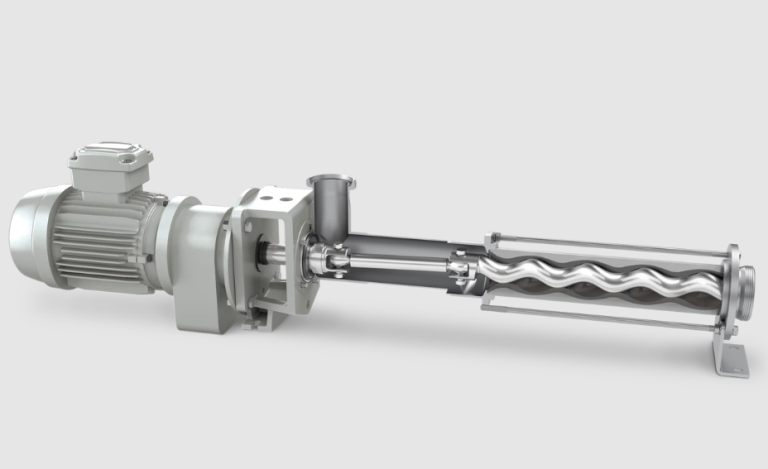

What is a screw pump? Screw pump is a part of the dry compressed gas transfer pump series. They are positive displacement pumps that use one or more screws to move fluid or water along the screw shaft. These screws interlock to pressurize the fluid and move it into the system. These screws engage each…

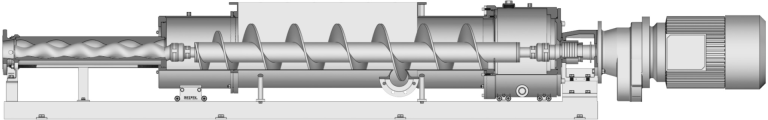

The Description of Screw Pump A screw pump is a type of positive displacement pump that utilizes an intermeshing screw and housing to transfer fluids or viscous substances. The pump consists of two or more screws (also known as rotors) that rotate in opposite directions, creating chambers that trap and move the fluid along the…

Introduction to Screw Pump Diagram. A screw pump diagram is a schematic representation of the working principle and components of a screw pump. Screw pumps are positive displacement pumps that use rotating screws to move fluids or slurries through a system. They are widely used in various industries due to their ability to handle high…

SANITARY PUMPS Low-shear, non-pulsating Sanitary Pumps transfer shear-sensitive materials with a minimum of turbulence or stress. People Also Ask

NEMO® BH Sanitary Advanced Pump in Compact Block Design NEMO® BH Sanitary Advanced Pump The NEMO BH hygienic pump in compact block design is used for hygienic applications in the food,pharmaceutical, cosmetic and chemical/biochemical industries because of its optimal process characteristics. People Also Ask

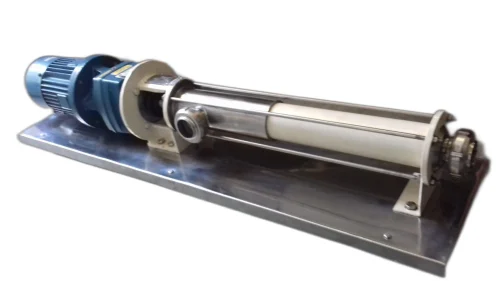

Sanitary Screw Pump Efficient and Hygienic Liquid Transfer Made Easy with Sanitary Screw Pumps Brief description: The sanitary screw pump meets the sanitary standards and is made of polished stainless steel. It can be customized with a cart funnel. It can transport a wide range of liquids with different types and viscosities. It can be…