-

-

PMV Pump Stator

What is Pump Stator Stators are metal tubes with internally molded cavities of synthetic or natural rubber. The rotor seals tightly against the flexible rubber inside the stator as it rotates, forming tightly sealed cavities which carry the liquid toward the discharge port.

-

-

Pump Screw-PMV Pump

People Also Ask

-

-

-

PMV Progressing Cavity Pump Manufacturers

What is PMV Progressing Cavity Pumps Manufacturers? PMV Pump Manufacture Co., Ltd was founded in 2003, is a professional pump enterprise integrating research, development, production, sales and service. Since its inception, quality management has always been the first goal. Therefore, we have designated staff responsible for raw material composition inspection, pump case bulge test, performance…

-

Type of Screw Pump-Pumpvv

What is a screw pump? Screw pump is a part of the dry compressed gas transfer pump series. They are positive displacement pumps that use one or more screws to move fluid or water along the screw shaft. These screws interlock to pressurize the fluid and move it into the system. These screws engage each…

-

Screw Pump-Pumpvv

The Description of Screw Pump A screw pump is a type of positive displacement pump that utilizes an intermeshing screw and housing to transfer fluids or viscous substances. The pump consists of two or more screws (also known as rotors) that rotate in opposite directions, creating chambers that trap and move the fluid along the…

-

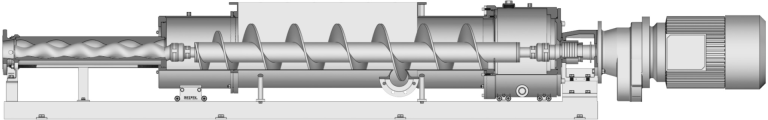

Screw Pump Diagram

Introduction to Screw Pump Diagram. A screw pump diagram is a schematic representation of the working principle and components of a screw pump. Screw pumps are positive displacement pumps that use rotating screws to move fluids or slurries through a system. They are widely used in various industries due to their ability to handle high…

screw pumps

The Description of Screw Pump

A screw pump is a type of positive displacement pump that utilizes an intermeshing screw and housing to transfer fluids or viscous substances. The pump consists of two or more screws (also known as rotors) that rotate in opposite directions, creating chambers that trap and move the fluid along the screw axis.

The Application of Screw Pump

Screw pumps are widely used in various industries for handling both thin and highly viscous liquids. They are commonly employed in oil and gas, chemical, food processing, wastewater treatment, and marine applications. Screw pumps are particularly suitable for pumping fluids with suspended solids, shear-sensitive materials, and high viscosity substances.

The Features of Screw Pump

1.High Efficiency: Screw pumps offer excellent efficiency levels due to their positive displacement design, ensuring a consistent flow rate even when handling challenging fluids.

2.Self-Priming Capability: These pumps are capable of self-priming, which means they can evacuate air from the system and start pumping without the need for external priming.

3.Gentle Fluid Handling: Screw pumps provide gentle fluid handling, making them suitable for delicate or shear-sensitive fluids that other pump types can damage.

4.Low Pulsation: The continuous flow of screw pumps results in minimal pulsation, providing a smooth and steady fluid transfer.

5.Viscosity Range: Screw pumps can handle a wide range of viscosity, from low-viscosity liquids to highly viscous substances, without losing their pumping efficiency.

Summary of Screw Pump

Screw pumps are versatile and reliable devices used for efficiently transferring fluids across various industries. Their positive displacement design, self-priming capability, gentle fluid handling, low pulsation, and ability to handle a wide viscosity range make them a preferred choice in many applications.