G series single screw pumps

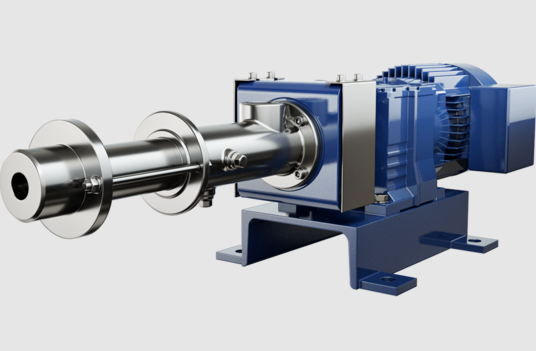

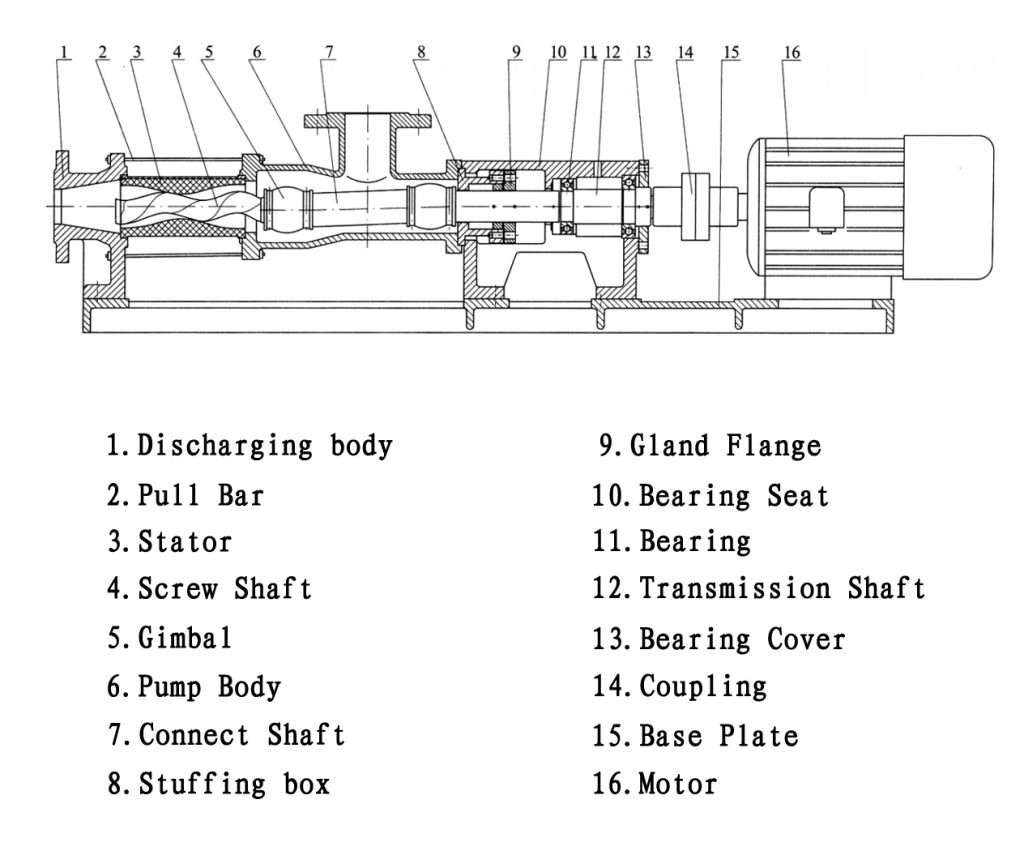

Single screw pumps are commonly called progressive cavity pumps. They work according to the positive displacement principle. The interference fit of the single-helix metal rotor and the double-helix elastic stator forms sealed cavitites. When the rotor moves inside the stator, the liquid moves in the axial direction from the suction port to the discharge port.

G series single screw pump is a name for progressive cavity pump in China, and it is also the earliest single screw pump in China.

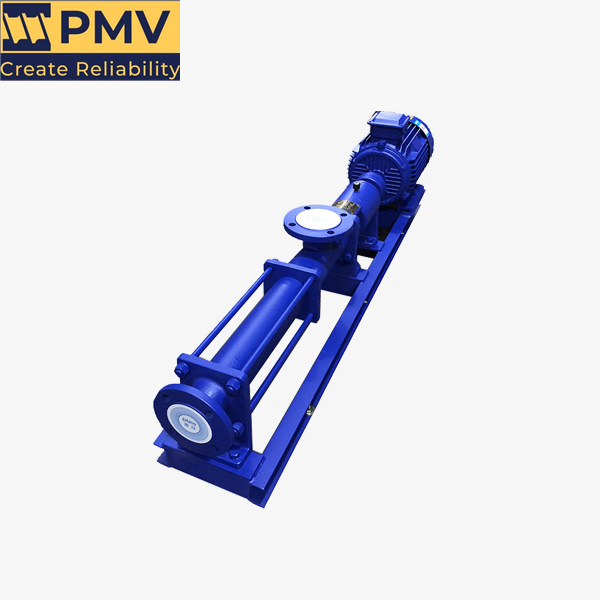

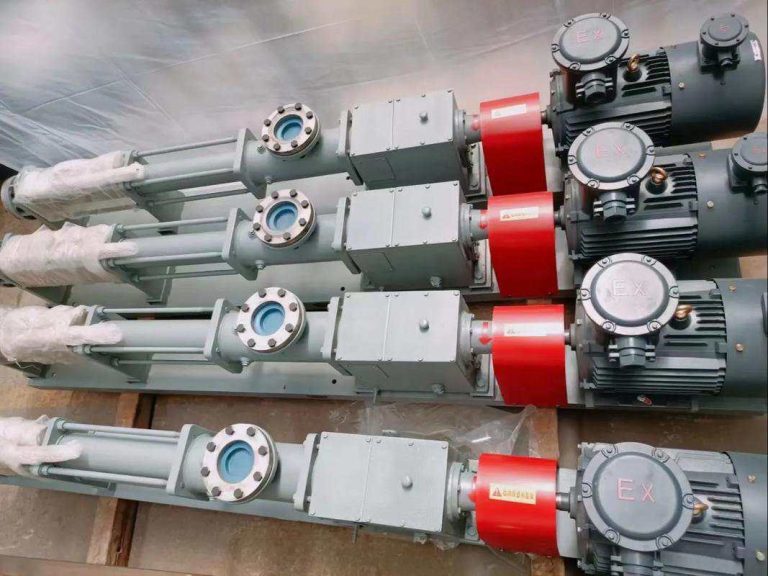

Without reducer

It is mainly used in sewage treatment and low viscosity medium transportation; Such pumps are usually mass-produced, so the price is often very advantageous.

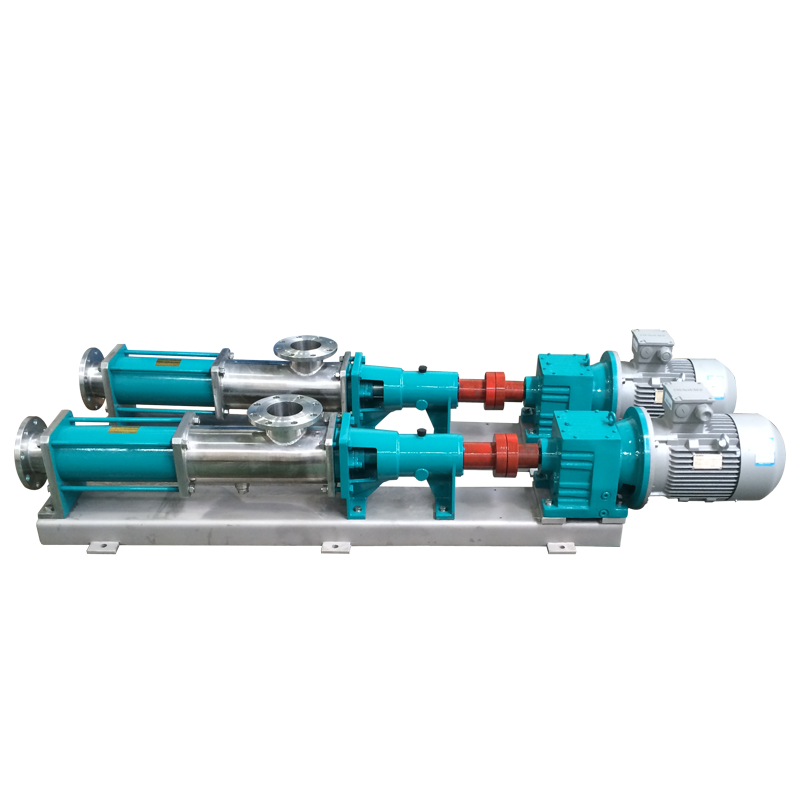

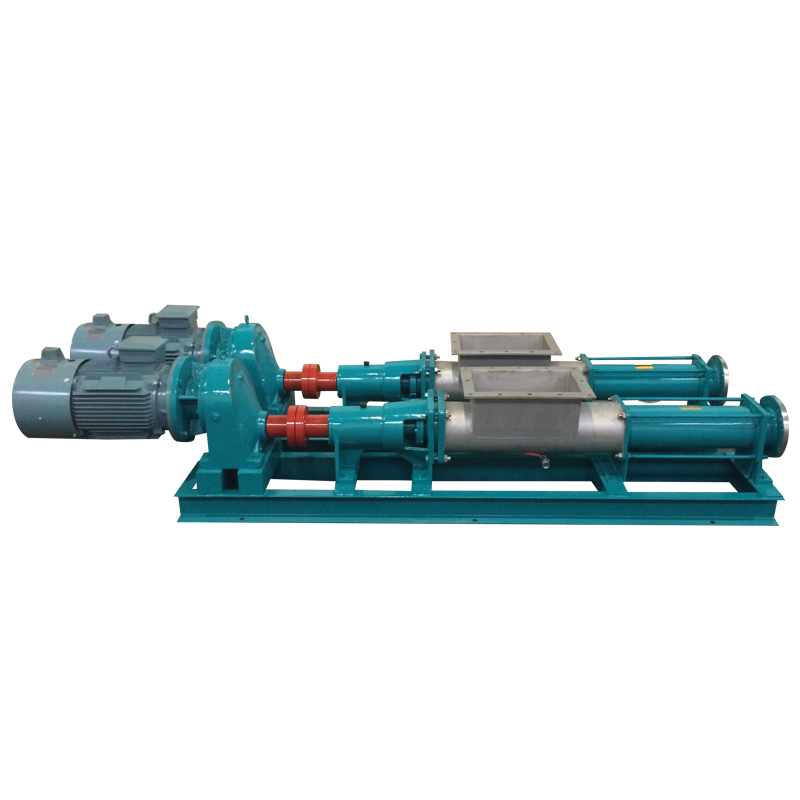

With reducer

(That is, progressive cavity pump with bearing seat.)

It is often used in the working conditions of large flow, high viscosity, poor fluidity and high pressure.

[video_lightbox_youtube video_id=”Cx2EmYbv-ls&rel=0″ width=”640″ height=”480″ alt=”G-type screw pump” anchor=”https://pumpvv.com/wp-content/uploads/2023/03/G-type-screw-pump-cover-1.jpg”]

Without reducer

- Simple structure

- Stable operation

- Packing / mechanical seal

- Transport medium with good fluidity, poor abrasiveness and low viscosity.

- Large stock

- Fast delivery

- Cheapness

With reducer

- High pressure stability

- Strong structure

- Low noise

- Long life cycle

- High efficiency

- Suitable for all kinds of media with high viscosity and solid particles

- The size can be customized according to your requirements.

G type single screw pump(without reducer) parameter table

| Type | Speed (rpm) | Flow (m³/h) | Pressure (Mpa) | Head (m) | Motor (Kw) | Inlet (mm) | Outlet (mm) | Allowable particle diameter (mm) | Allowable fiber length (mm) |

|---|---|---|---|---|---|---|---|---|---|

| G20-1 | 960 | 0.8 | 0.6 | 60 | 0.75 | DN25 | DN25 | 1.5 | 25 |

| G20-2 | 960 | 0.8 | 1.2 | 120 | 1.1 | DN25 | DN25 | 1.5 | 25 |

| G25-1 | 960 | 2 | 0.6 | 60 | 1.5 | DN32 | DN25 | 2 | 30 |

| G25-2 | 960 | 2 | 1.2 | 120 | 2.2 | DN32 | DN25 | 2 | 30 |

| G30-1 | 960 | 5 | 0.6 | 60 | 2.2 | DN50 | DN40 | 2.5 | 35 |

| G30-2 | 960 | 5 | 1.2 | 120 | 3 | DN50 | DN40 | 2.5 | 35 |

| G35-1 | 960 | 8 | 0.6 | 60 | 3 | DN65 | DN50 | 3 | 40 |

| G35-2 | 960 | 8 | 1.2 | 120 | 4 | DN65 | DN50 | 3 | 40 |

| G40-1 | 960 | 12 | 0.6 | 60 | 4 | DN80 | DN65 | 3.8 | 45 |

| G40-2 | 960 | 12 | 1.2 | 120 | 5.5 | DN80 | DN65 | 3.8 | 45 |

| G50-1 | 960 | 20 | 0.6 | 60 | 5.5 | DN100 | DN80 | 5 | 50 |

| G50-2 | 960 | 20 | 1.2 | 120 | 7.5 | DN100 | DN80 | 5 | 50 |

| G60-1 | 960 | 30 | 0.6 | 60 | 11 | DN125 | DN100 | 6 | 60 |

| G60-2 | 960 | 30 | 1.2 | 120 | 11 | DN125 | DN100 | 6 | 60 |

| G70-1 | 720 | 45 | 0.6 | 60 | 11 | DN150 | DN125 | 8 | 70 |

| G70-2 | 720 | 45 | 1.2 | 120 | 15 | DN150 | DN125 | 8 | 70 |

| G85-1 | 720 | 60 | 0.6 | 60 | 11 | DN150 | DN150 | 10 | 80 |

| G85-2 | 720 | 60 | 1.2 | 120 | 15 | DN150 | DN150 | 10 | 80 |

G type single screw pump(without reducer) parameter table

G type single screw pump(with reducer) parameter table

| Pump Type | Capacity Range (m³/h) | Pressure Range (bar) | Recommended speed (rpm) | Transmission ratio range | Shaft power range (Kw) |

|---|---|---|---|---|---|

| G10-1 | 0.060~0.104 | 6 | 230~362 | 6.3~4.0 | ≤0.55 |

| G10-2 | 0.030~0.054 | 12 | 230~362 | 6.3~4.0 | ≤0.55 |

| G15-1 | 0.12~0.21 | 6 | 230~362 | 6.3~4.0 | ≤0.55 |

| G15-2 | 0.12~0.22 | 12 | 230~362 | 6.3~4.0 | ≤0.55 |

| G20-1 | 0.25~0.52 | 6 | 204~362 | 7.1~4.0 | ≤0.55 |

| G20-2 | 0.25~0.52 | 12 | 204~362 | 7.1~4.0 | ≤0.75 |

| G30-1 | 0.5~0.98 | 6 | 204~362 | 7.1~4.0 | ≤0.55 |

| G30-2 | 0.5~1.0 | 12 | 204~362 | 7.1~4.0 | ≤1.1 |

| G35-1 | 0.85~2.0 | 6 | 204~362 | 7.1~4.0 | ≤0.75 |

| G35-2 | 0.85~2.1 | 12 | 204~362 | 7.1~4.0 | ≤2.2 |

| G40-1 | 1.6~3.5 | 6 | 204~362 | 7.1~4.0 | ≤2.2 |

| G40-2 | 1.65~3.7 | 12 | 204~362 | 7.1~4.0 | ≤3 |

| G50-1 | 2.6~8.2 | 6 | 181~362 | 8.0~4.0 | ≤3 |

| G50-2 | 2.7~8.4 | 12 | 181~362 | 8.0~4.0 | ≤5.5 |

| G60-1 | 3.8~11.2 | 6 | 161~362 | 9.0~4.0 | ≤3 |

| G60-2 | 3.8~11.3 | 12 | 161~362 | 9.0~4.0 | ≤5.5 |

| G70-1 | 4.0~16.5 | 6 | 145~362 | 10.0~4.0 | ≤7.5 |

| G70-2 | 4.0~17 | 12 | 145~362 | 10.0~4.0 | ≤15 |

| G85-1 | 7.5~34 | 6 | 129~362 | 11.2~4.0 | ≤11 |

| G85-2 | 8.0~35 | 12 | 129~362 | 11.2~4.0 | ≤18.5 |

| G105-1 | 18~70 | 6 | 129~362 | 11.2~4.0 | ≤22 |

| G105-2 | 19~72 | 12 | 129~362 | 11.2~4.0 | ≤45 |

| G135-1 | 30~112 | 6 | 102~290 | 14.2~5.0 | ≤30 |

| G135-2 | 32~116 | 12 | 102~290 | 14.2~5.0 | ≤75 |

G type single screw pump(with reducer) parameter table

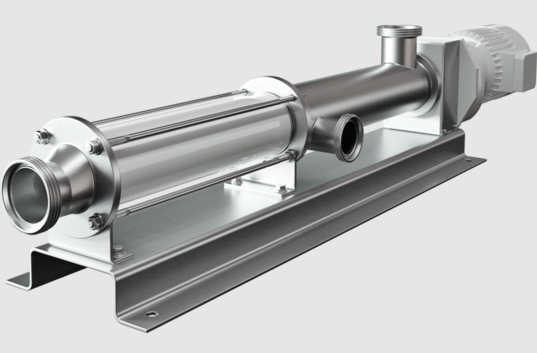

Direct-connected progressing cavity pump can be used to transport neutral or corrosive liquids, clean and abrasive liquids, liquids containing gas or easily generating bubbles, and liquids with high viscosity or low viscosity (including liquids containing fibers or solid substances)

Environmental protection: the transportation of industrial sewage, domestic sewage and sludge turbid water containing solid particles and short fibers, especially suitable for oil-water separators, plate filter presses and other equipment

Shipbuilding industry: used for transporting residual oil, cleaning tanks, sewage, seawater, etc.;

Petrochemical industry: used for transportation of various oils, especially crude oil;

Textile industry: used for conveying synthetic fiber liquid, viscose liquid, dye, nylon powder, etc.

Medicine and daily chemicals: transportation of various viscous pastes, emulsions and various ointment cosmetics, etc.

Canned food industry: transportation of all kinds of sticky starch, edible oil, honey, sugar sauce, fruit pulp, cream, fish and leftovers;

Brewing industry: all kinds of fermented viscous liquids, concentrated distiller’s grains, grain product residues, all kinds of sauces, pulps and mucus containing massive solid substances, etc.;

Construction industry: spraying and conveying of cement slurry, lime slurry, paint and other pastes;

Metallurgy and mining industry: used to transport oxides and wastewater, mine drainage and liquid explosives, etc.;

Chemical industry: transportation of various suspensions, grease, colloidal slurries, adhesives, paper making, printing, high viscosity ink, black liquor of paper pulp, PVC polymer plastic paste of paper, pulp with various concentrations, short fiber slurry, etc.

screw pump stator

G single screw pump wholesale price list of different materials( without reducer )

Cast iron G type single screw pump ex-factory price list

| Type | Flow (m³/h) | Motor (Kw) | Head (m) | Inlet (mm) | Outlet (mm) | Pump with base (without motor) | Whole pump |

|---|---|---|---|---|---|---|---|

| G20-1 | 0.8 | 0.75 | 60 | DN25 | DN25 | $180 | $260 |

| G20-2 | 0.8 | 1.1 | 120 | DN25 | DN25 | $240 | $330 |

| G25-1 | 2 | 1.5 | 60 | DN32 | DN25 | $260 | $380 |

| G25-2 | 2 | 2.2 | 120 | DN32 | DN25 | $310 | $460 |

| G30-1 | 5 | 2.2 | 60 | DN50 | DN40 | $320 | $470 |

| G30-2 | 5 | 3 | 120 | DN50 | DN40 | $400 | $600 |

| G35-1 | 8 | 3 | 60 | DN65 | DN50 | $380 | $580 |

| G35-2 | 8 | 4 | 120 | DN65 | DN50 | $440 | $670 |

| G40-1 | 12 | 4 | 60 | DN80 | DN65 | $400 | $630 |

| G40-2 | 12 | 5.5 | 120 | DN80 | DN65 | $450 | $720 |

| G50-1 | 20 | 5.5 | 60 | DN100 | DN80 | $530 | $800 |

| G50-2 | 20 | 7.5 | 120 | DN100 | DN80 | $650 | $1030 |

| G60-1 | 30 | 11 | 60 | DN125 | DN100 | $780 | $1240 |

| G60-2 | 30 | 11 | 120 | DN125 | DN100 | $940 | $1550 |

| G70-1 | 45 | 11 | 60 | DN150 | DN125 | $1160 | $1780 |

| G70-2 | 45 | 15 | 120 | DN150 | DN125 | $1650 | $2440 |

| G85-1 | 60 | 11 | 60 | DN150 | DN150 | $1640 | $2650 |

| G85-2 | 60 | 15 | 120 | DN150 | DN150 | $2360 | $3140 |

Cast iron G type single screw pump ex-factory price list

- Stator: NBR

- Rotor: Bearing steel

- Pump body: Cast Iron

- Seal: Packing seal

If you need other materials and configurations, please contact us.

SS304 G type single screw pump ex-factory price list

| Type | Flow (m³/h) | Motor (Kw) | Head (m) | Inlet (mm) | Outlet (mm) | Pump with base (without motor) | Whole pump |

|---|---|---|---|---|---|---|---|

| G20-1 | 0.8 | 0.75 | 60 | DN25 | DN25 | $310 | $360 |

| G20-2 | 0.8 | 1.1 | 120 | DN25 | DN25 | $340 | $430 |

| G25-1 | 2 | 1.5 | 60 | DN32 | DN25 | $460 | $530 |

| G25-2 | 2 | 2.2 | 120 | DN32 | DN25 | $490 | $640 |

| G30-1 | 5 | 2.2 | 60 | DN50 | DN40 | $550 | $650 |

| G30-2 | 5 | 3 | 120 | DN50 | DN40 | $590 | $800 |

| G35-1 | 8 | 3 | 60 | DN65 | DN50 | $650 | $800 |

| G35-2 | 8 | 4 | 120 | DN65 | DN50 | $660 | $890 |

| G40-1 | 12 | 4 | 60 | DN80 | DN65 | $660 | $840 |

| G40-2 | 12 | 5.5 | 120 | DN80 | DN65 | $690 | $960 |

| G50-1 | 20 | 5.5 | 60 | DN100 | DN80 | $970 | $1160 |

| G50-2 | 20 | 7.5 | 120 | DN100 | DN80 | $1070 | $1450 |

| G60-1 | 30 | 11 | 60 | DN125 | DN100 | $1360 | $1700 |

| G60-2 | 30 | 11 | 120 | DN125 | DN100 | $1550 | $2160 |

| G70-1 | 45 | 11 | 60 | DN150 | DN125 | $1820 | $2260 |

| G70-2 | 45 | 15 | 120 | DN150 | DN125 | $2380 | $3170 |

| G85-1 | 60 | 11 | 60 | DN150 | DN150 | $2500 | $3280 |

| G85-2 | 60 | 15 | 120 | DN150 | DN150 | $3070 | $3900 |

SS304 G type single screw pump ex-factory price list

- Stator: NBR

- Rotor: SS304

- Pump body: SS304

- Seal: Packing seal

If you need other materials and configurations, please contact us.

Food hygiene grade SS304 G type single screw pump ex-factory price list

| Type | Flow (m³/h) | Motor (Kw) | Head (m) | Inlet (mm) | Outlet (mm) | Pump with base (without motor) | Whole pump |

|---|---|---|---|---|---|---|---|

| G20-1 | 0.8 | 0.75 | 60 | DN25 | DN25 | $320 | $400 |

| G20-2 | 0.8 | 1.1 | 120 | DN25 | DN25 | $400 | $490 |

| G25-1 | 2 | 1.5 | 60 | DN32 | DN25 | $460 | $580 |

| G25-2 | 2 | 2.2 | 120 | DN32 | DN25 | $540 | $690 |

| G30-1 | 5 | 2.2 | 60 | DN50 | DN40 | $550 | $700 |

| G30-2 | 5 | 3 | 120 | DN50 | DN40 | $650 | $850 |

| G35-1 | 8 | 3 | 60 | DN65 | DN50 | $650 | $850 |

| G35-2 | 8 | 4 | 120 | DN65 | DN50 | $730 | $960 |

| G40-1 | 12 | 4 | 60 | DN80 | DN65 | $660 | $900 |

| G40-2 | 12 | 5.5 | 120 | DN80 | DN65 | $750 | $1020 |

| G50-1 | 20 | 5.5 | 60 | DN100 | DN80 | $980 | $1250 |

| G50-2 | 20 | 7.5 | 120 | DN100 | DN80 | $1200 | $1580 |

| G60-1 | 30 | 11 | 60 | DN125 | DN100 | $1360 | $1830 |

| G60-2 | 30 | 11 | 120 | DN125 | DN100 | $1600 | $2210 |

| G70-1 | 45 | 11 | 60 | DN150 | DN125 | $2000 | $2600 |

| G70-2 | 45 | 15 | 120 | DN150 | DN125 | $2610 | $3400 |

| G85-1 | 60 | 11 | 60 | DN150 | DN150 | $2470 | $3480 |

| G85-2 | 60 | 15 | 120 | DN150 | DN150 | $3850 | $4730 |

Food hygiene grade SS304 G type single screw pump ex-factory price list x-factory price list

- Stator: Food grade rubber / Silica gel

- Rotor: SS304

- Pump body: SS304

- Seal: Packing seal

If you need other materials and configurations, please contact us.