G Type Single Screw Pump

Single Screw Pump Operating Principle and Benefits

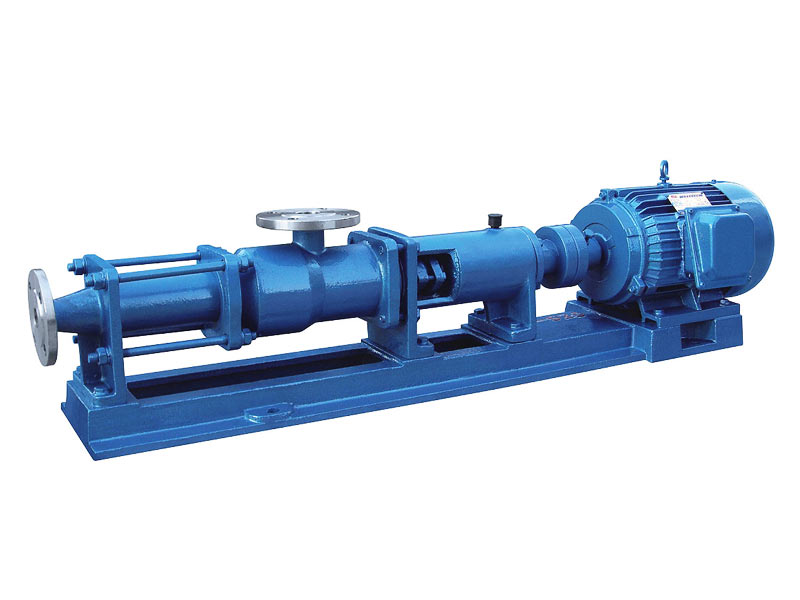

Single screw pump is a type of rotary positive displacement pump that operates based on the positive displacement principle. The pump works by creating sealed cavities through the interference fit of a single-helix metal rotor and a double-helix elastic stator.

Due to the special geometry of the two parts, separate sealing chambers are formed. The medium flows uniformly from the axial direction. The internal flow rate is low, the volume remains unchanged, and the pressure is stable. Therefore, there is no eddy current and agitation. The output pressure of each pump is 0.6MPa, the lift is 60m (clear water), and the self-priming height is generally 6m. It is suitable for conveying medium temperature below 80 ℃ (special requirements can reach 150 ℃).

Introduction and Technical Specifications of Single Screw Pump

Single screw pump is a new type of pump which works according to the principle of rotary meshing volume type. The main working parts are eccentric screw (rotor) and fixed bushing (stator).

Due to the special geometry of the two parts, separate sealing chambers are formed. The medium flows uniformly from the axial direction. The internal flow rate is low, the volume remains unchanged, and the pressure is stable. Therefore, there is no eddy current and agitation. The output pressure of each pump is 0.6MPa, the lift is 60m (clear water), and the self-priming height is generally 6m. It is suitable for conveying medium temperature below 80 ℃ (special requirements can reach 150 ℃).

Because the stator is made of a variety of elastic materials, this kind of pump is not competent for the transportation of high viscosity fluid and medium containing hard suspended particles or fiber. The flow rate is proportional to the rotational speed.

Transmission can be directly driven by coupling, or speed control motor, V-belt, gearbox and other devices.

This kind of pump has the advantages of less parts, compact structure, small volume and easy maintenance. The rotor and stator are vulnerable parts of the pump, and the structure is simple and easy to assemble and disassemble.

technical parameter

Flow: 0-150m3 / h;

Lift: 60-120m;

Power: 0.75-37kw;

Speed: 500-960r / min;

Caliber: 20-135mm;

Temperature: – 15-200 ℃

Model meaning

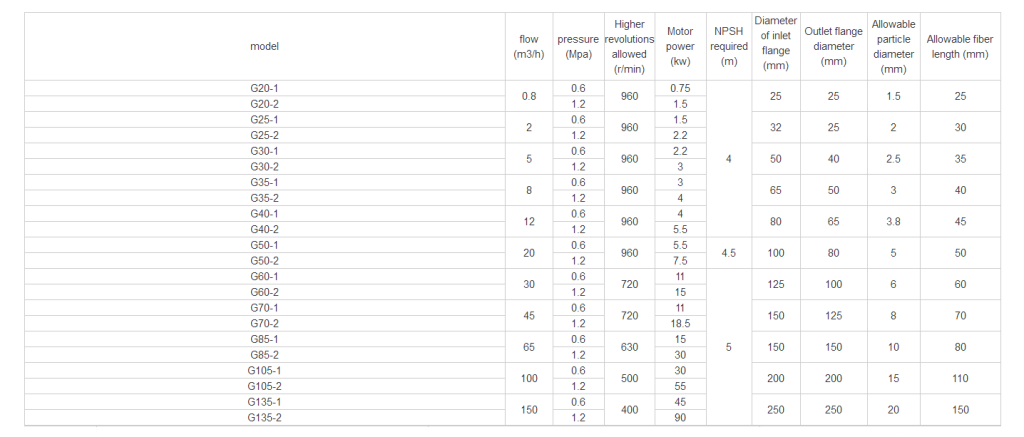

G Type Single Screw Pump List

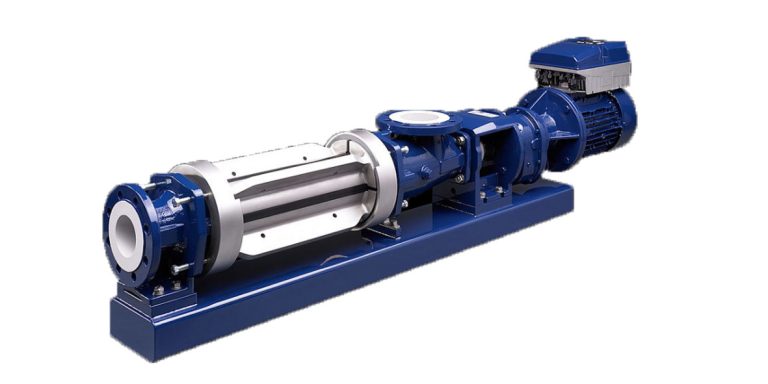

The Advantages and Applications of G-Type Screw Pump

The G-type screw pump has the advantages of compact structure, small volume and easy maintenance. It has strong adaptability to medium, stable flow rate, small pressure fluctuation and high self absorption ability. The working temperature can reach 120 ℃. If it is necessary to transport 120 ℃ – 350 ℃ high temperature medium, it can be customized. It is widely used in food, metallurgy, papermaking, printing and dyeing, chemical industry, chemical fertilizer, pharmaceutical and other industrial sectors.screw pump geometry

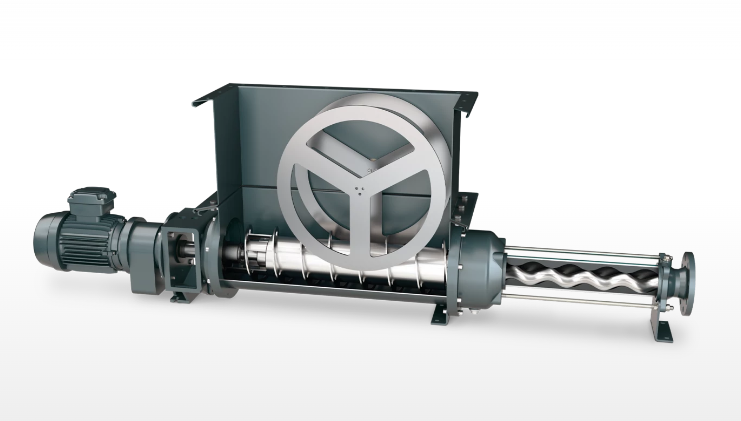

The screw pump rotor

The screw pump rotor is a vital component of a screw pump system. It is a helical-shaped rotating element that works in conjunction with the stator to create a sealed cavity and transfer fluid. The rotor’s design and precise manufacturing ensure efficient fluid displacement and minimal pulsation. It is typically made of high-quality materials such as stainless steel or hardened alloys to resist wear and corrosion. The screw pump rotor’s geometry and surface finish contribute to its ability to handle various types of fluids, including viscous and abrasive substances. Its reliable performance and durability make it a critical element in achieving consistent and reliable fluid transfer in screw pump applications.

The screw pump chart

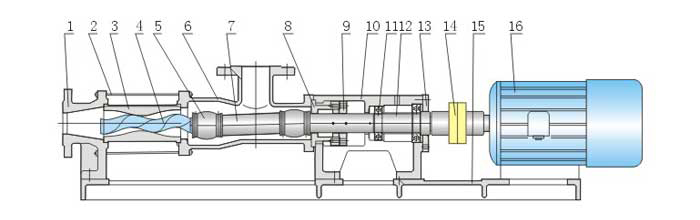

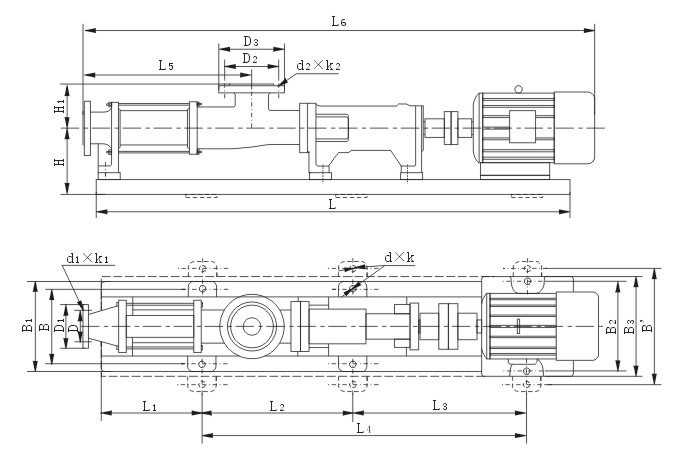

screw pump diagram

[video_lightbox_youtube video_id=”Cx2EmYbv-ls&rel=0″ width=”640″ height=”480″ alt=”G-type screw pump” anchor=”https://pumpvv.com/wp-content/uploads/2023/03/G-type-screw-pump-cover-1.jpg”]

People Also Ask

Send Your Enquiry :