G Type Single Screw Pump

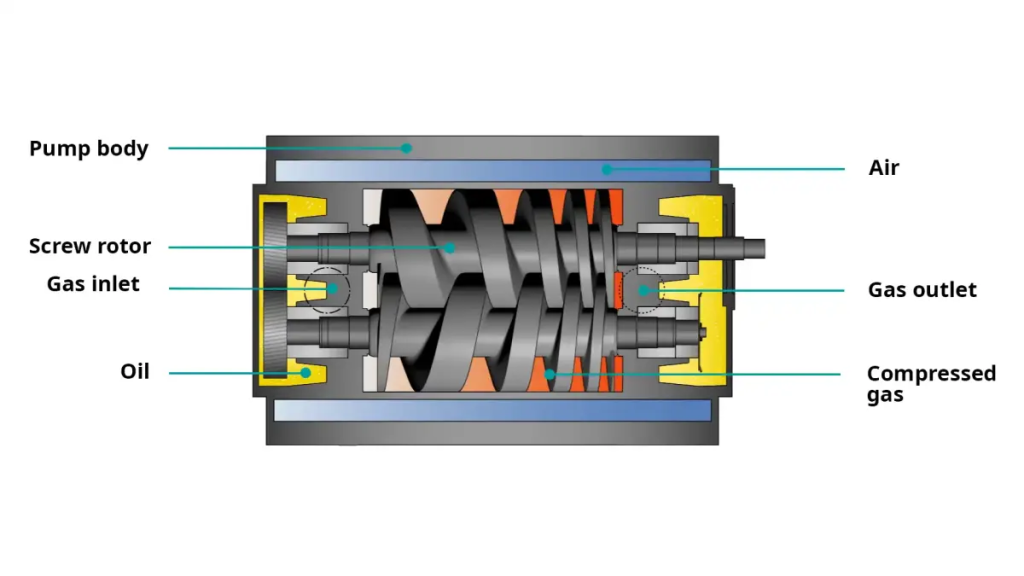

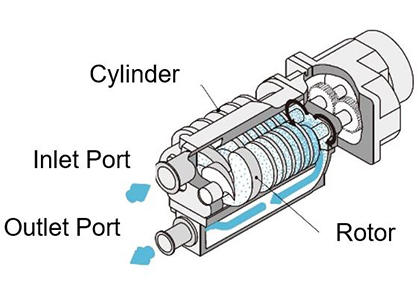

G Type Single Screw Pump Single Screw Pump Operating Principle and Benefits Single screw pump is a type of rotary positive displacement pump that operates based on the positive displacement principle. The pump works by creating sealed cavities through the interference fit of a single-helix metal rotor and a double-helix elastic stator. Due to the…